The CPU you see looks like this:

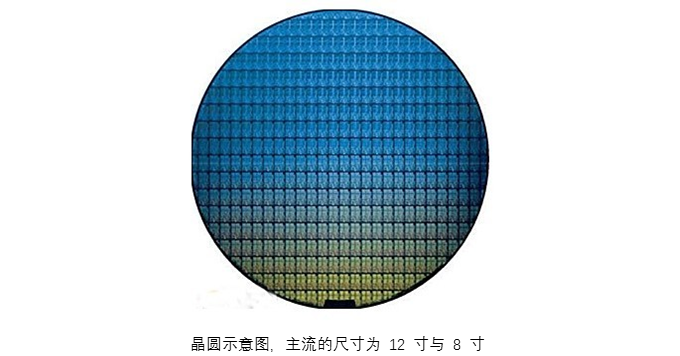

This is the packaged form. The shell and silicon circuit board are actually worthless. The most expensive part comes from the chip inside. The chip is in this wafer form before it is cut:

Those who have no idea about chips and the semiconductor industry can watch this film to catch up.

The longer you stay in this industry, the more you will feel that the chip business is really super difficult to do. Why is our country now developing the semiconductor/chip industry with the whole country's strength instead of relying on the spontaneous behavior of the market?

One of the most important reasons is that the cost is too high. Without policy and financial support from the national level, almost no company can survive the huge, money-burning investment in the R&D and startup stages.

In what aspects are the costs high?

1. High tape-out cost

Before mass production, a small number of wafer verifications are required. Although the number of wafers is small, the number of photomasks is not less. The photolithography steps of the CPU are about one or two hundred steps, and each step requires a photomask. The cost of the photomask accounts for a large part of the cost of the wafer production stage.

The patterns in the mask are extremely fine and difficult to manufacture, so they are expensive.

After tape-out, it is often discovered that the pattern design in the mask needs to be optimized, and this optimization is not limited to one layer of the mask. In many cases, multiple layers of masks need to be modified at the same time, which further increases the cost.

2. High process cost

The process steps of advanced CPU chips are about 1000-3000 steps. Each step has material costs. Cheap processes like scrubbing cost about one cent or one gross per chip. The cost of some steps may reach hundreds of yuan, for example, if expensive materials are used. The sum of all the steps is a relatively large number.

The more advanced the chip, the more complex the chip structure and the more process steps there are, so the cost per wafer will be higher.

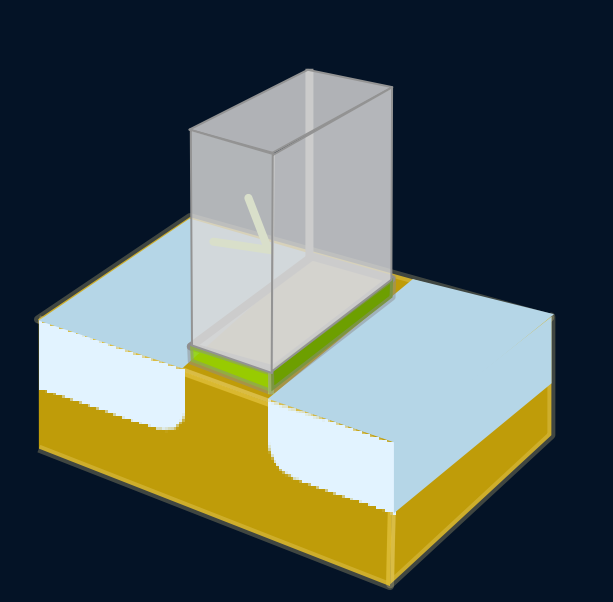

Take the simplest MOSFET (metal oxide semiconductor field effect transistor) structure as an example. The early MOSFET had the following physical structure:

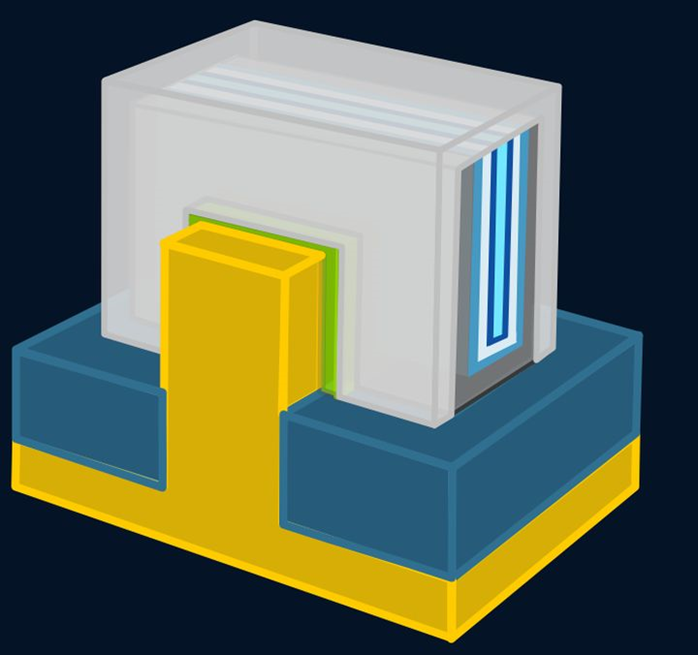

Now, MOSFET has evolved into FinFET (Fin Field Effect Transistor), and the process steps have obviously increased. It looks like this:

In addition to material costs, the production clean room needs to be powered 24 hours a day, 365 days a year. Air purification, humidity maintenance, constant temperature maintenance, and pollution particle removal in such a large space all require electricity costs. Some media even broke the news that about one-third of the increase in Taiwan's electricity consumption was contributed by TSMC. This shows how much electricity semiconductor production lines consume.

3. High equipment cost

Semiconductor factory production equipment is extremely expensive, and the price of consumable parts of many equipment is enough to easily buy a Land Rover. The depreciation cost of the equipment will naturally be converted into the cost of the chip.

The most expensive one is the photolithography machine because the process it needs to achieve is too sophisticated.

4. High risk cost

The more advanced the process and product, the higher the requirements for product technology. From the first step to the final processing of the wafer, advanced chips often take several months to complete this process. They can "die" halfway at any time, including but not limited to the following ways of death:

1) The technician was distracted by his girlfriend and installed the wrong equipment part.

2) Equipment malfunctions but no alarm is given, resulting in process deviation.

3) The automation system crashed...

4) The wafers were not used to the local climate and for unknown reasons broke into pieces in the FOUP (container for wafers).

5) He was thrown away during the rotation and smashed to pieces...

There are many reasons. Let’s not talk about the failure of the process itself. It’s lucky to be able to avoid various accidents and rush to the last step. And those “dead” wafers cannot die in vain, and they will be reflected in the selling price of the chip.

Even the most advanced factories cannot avoid these risk events. TSMC once scrapped 100,000 wafers due to risky processes, of course, this was due to its poor supplier Dow Chemical.

TSMC's 10,000 wafers scrapped may be caused by Japanese companies Shin-Etsu, JSR and Dow Chemical

In addition to these, there are also chip design costs, labor costs, packaging costs, transportation costs, sales promotion costs...

After reading this, do you still think that CPU is expensive? A CPU that has gone through thousands of processing steps and is the product of almost all the wisdom of mankind, only costs a few thousand yuan after adding up all the costs. It is really cheap.

Previous article:Cross-border "chip manufacturing", 15 listed companies entered the semiconductor industry through mergers and acquisitions

Next article:ON Semiconductor: Automotive chip shortage will not be alleviated until the second half of the year at the latest

Recommended ReadingLatest update time:2024-11-15 02:35

- Popular Resources

- Popular amplifiers

-

Learn CPLD and Verilog HDL programming technology from scratch_Let beginners easily learn CPLD system design technology through practical methods

Learn CPLD and Verilog HDL programming technology from scratch_Let beginners easily learn CPLD system design technology through practical methods -

MCU C language programming and Proteus simulation technology (Xu Aijun)

MCU C language programming and Proteus simulation technology (Xu Aijun) -

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang) -

Principles and Applications of Single Chip Microcomputers 3rd Edition (Zhang Yigang)

Principles and Applications of Single Chip Microcomputers 3rd Edition (Zhang Yigang)

- Red Hat announces definitive agreement to acquire Neural Magic

- 5G network speed is faster than 4G, but the perception is poor! Wu Hequan: 6G standard formulation should focus on user needs

- SEMI report: Global silicon wafer shipments increased by 6% in the third quarter of 2024

- OpenAI calls for a "North American Artificial Intelligence Alliance" to compete with China

- OpenAI is rumored to be launching a new intelligent body that can automatically perform tasks for users

- Arm: Focusing on efficient computing platforms, we work together to build a sustainable future

- AMD to cut 4% of its workforce to gain a stronger position in artificial intelligence chips

- NEC receives new supercomputer orders: Intel CPU + AMD accelerator + Nvidia switch

- RW61X: Wi-Fi 6 tri-band device in a secure i.MX RT MCU

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- How to quickly start embedded system development

- Cheer for the college entrance examination

- Mathematical formula solving

- TI millimeter wave radar evaluation report summary

- Share experience [RK3399] Type-C to normal USB

- [TI recommended course] #Live replay: TI's new generation C2000? microcontroller#

- IAR burning program shows error

- Application of state machine principle in control program design.pdf

- The board has been mailed, please check the courier number in the post~

- Crazy Shell AI open source drone timer (LED flight status light, indicator light flashing)

Learn CPLD and Verilog HDL programming technology from scratch_Let beginners easily learn CPLD system design technology through practical methods

Learn CPLD and Verilog HDL programming technology from scratch_Let beginners easily learn CPLD system design technology through practical methods

京公网安备 11010802033920号

京公网安备 11010802033920号