Intel announces annual progress on net-zero greenhouse gas emissions commitment

In April 2022, Intel committed to achieving net-zero greenhouse gas emissions from its global operations by 2040. This is a further improvement of Intel's requirements based on its original commitment to accelerate industry-wide emission reductions. Recently, Keyvan Esfarjani, Intel's executive vice president, chief global operating officer and general manager of manufacturing supply chain and operations, published a signed article summarizing the progress Intel has made in the year since the commitment was released. The following is the full text:

For decades, Intel has brought technological advancement while also shouldering high standards of environmental protection responsibilities. Today, the journey continues.

Last April, Intel CEO Pat Gelsinger outlined Intel's commitment to reducing greenhouse gas emissions across its own operations and throughout its value chain, which included increasing requirements on its original commitments and establishing a We will achieve net-zero emissions of Scope 1 and Scope 2 greenhouse gas emissions from our global operations by 2040.

Due to the energy consumption caused by manufacturing chips and the unique technical requirements in the process, reducing greenhouse gas emissions is one of the most complex and severe challenges currently facing the semiconductor industry. It is even more difficult for the entire ecosystem to work hard to reduce its carbon footprint while vigorously expanding its global business to meet growing chip demand. To achieve net-zero emissions, we will need to develop and test new green chemicals, emission reduction solutions, equipment designs and facility systems, many of which do not yet exist on the market and await further exploration. As one of the world's largest semiconductor companies, spanning research, design and manufacturing, we are accelerating more sustainable computing by deepening our long-standing collaborations across the ecosystem.

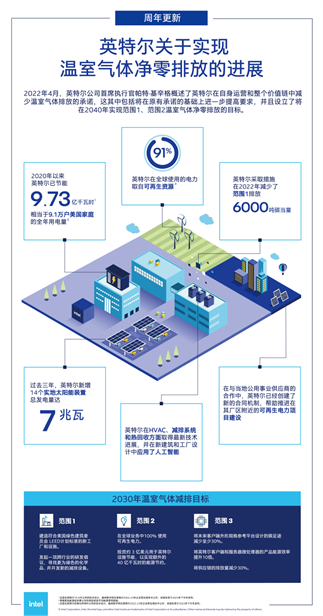

We are increasing our sustainability efforts to drive net-zero greenhouse gas emissions in three key areas. First, we developed a roadmap for reducing emissions from our production facilities and office buildings, which includes investments in renewable energy: by the end of 2022, our global renewable electricity usage exceeded 90%1. Second, we are working with industry and academia to develop alternatives to chemicals used in semiconductor processing and manufacturing and improve energy efficiency throughout the value chain, while establishing a system of standard reporting metrics. Third, we are improving the energy efficiency of our products and platforms to reduce our overall carbon footprint, which will also help our customers achieve their sustainability goals. For example, for data center operators, using 4th generation Intel® Xeon® Scalable processors can reduce carbon emissions by up to 60%2.

We remain focused on opportunities to achieve our shared goal of net-zero greenhouse gas emissions and help mitigate the impacts of climate change. I’m very proud of our collaboration so far, and I’m excited to share more details on our progress with you.

Reduce emissions at every stage of operations

Intel will continue to purchase renewable electricity and invest in the construction of related power generation facilities. Currently, Intel is actively promoting the construction of utility-scale renewable power projects near major manufacturing plants and new factories around the world, including the use of solar and wind energy, by working with local utilities to create new contract mechanisms. We have added 14 new solar installations in the park, with a total power generation capacity of up to 7 megawatts, which will bring Intel's global solar power generation capacity to more than 30 megawatts. By the end of 2022, our global renewable electricity usage has increased from 80% in 2021 to approximately 91%3. In order to achieve the goal of using 100% renewable electricity for our global business by 2030, we are committed to exploring some reliable and scalable renewable electricity development opportunities.

In order to further reduce our impact on the environment and help our customers reduce their carbon footprint while also reducing our operating costs, we have adopted energy-saving and efficiency-enhancing measures in every aspect of our operations. Since 2020, Intel has saved approximately 973 million kilowatt-hours4 through HVAC cooling, compressed air efficiency and other measures - equivalent to the annual electricity consumption of 91,000 U.S. households5. In 2022, we will use heat recovery measures As well as reducing heating demand, it successfully reduced direct energy emissions by 6,000 tons of carbon equivalent.

Going forward, we are committed to investing in unique technologies to further reduce our carbon footprint. This includes continuously upgrading and improving our systems to maximize the use of waste heat from the plant, thereby reducing reliance on natural gas. At the same time, we will also develop ultra-efficient emission reduction equipment and use the latest artificial intelligence technology, software systems and energy efficiency to create corresponding technologies to reduce reliance on fossil fuels in factory design and strive to eliminate the use of fossil fuels.

Working with the value chain

Intel is working with industry organizations Semiconductor Industries International (SEMI) and the Semiconductor Research Alliance to create the Sustainable Semiconductor Manufacturing initiative to develop safer alternatives to the various chemicals used in semiconductor manufacturing. At the same time, we are collaborating with other industry-leading partners to drive changes throughout the ecosystem for the better.

The newly created Semiconductor Climate Alliance brings together our suppliers, industry partners and customers to accelerate the development of solutions that reduce the industry’s greenhouse gas emissions. As a founding member of the Alliance, we set an example. Currently, more than 70 companies across the entire value chain have participated.

At the same time, we joined the Product Attribute Impact Algorithm Consortium sponsored by MIT to develop a universal method to calculate the carbon footprint of electronic products. Not only will this help our industry better measure the progress being made today, it will also give customers clear visibility into upstream emissions and the carbon emissions embodied in their products.

In addition, we recently announced a European academic research initiative with Merck KGaA in Darmstadt, Germany. It will focus on using artificial intelligence and machine learning technology to promote innovation in semiconductor manufacturing processes and technologies.

Improving energy efficiency of Intel products and platforms

The new generation of Intel products is designed to achieve dual improvements in performance and energy efficiency. Intel has launched the fourth-generation Intel® Xeon® Scalable processor, a highly sustainable data center processor that uses built-in accelerators to increase performance per watt by an average of 2.9 times for specific workloads6. Its other features can save up to 20% of energy with little impact on performance7 when handling specific workloads.

To reduce the generation of electronic waste, Intel is working with the Open Compute Project (OCP) to promote modular design so that more server components can be reused in iterations.

By combining the above measures with operational efforts, we are helping customers accelerate sustainable development with a comprehensive strategy covering products, platforms, software and solutions.

Commitment to achieve net-zero greenhouse gas emissions

Leadership means more responsibility. Environmental commitments and greenhouse gas emission reductions are not nice-to-haves but imperatives. This is an opportunity that requires the entire value chain to come together and innovate to achieve a common goal, and no one company can do this alone.

Intel remains fully committed to taking the necessary actions, investing, collaborating and innovating to achieve net-zero greenhouse gas emissions from our business. I am pleased with the progress we have made so far and look forward to even more achievements we will achieve in the future.

1 This is a preliminary estimate disclosed in Intel's proxy statement. The final numbers will be made public in Intel's 2022-23 Corporate Responsibility Report, which will be released in the second half of 2023.

2Calculations as of March 28, 2023, based on Intel® Total Node Cost and Power Calculator, using default cost, power, and total cost assumptions, 50 units using Intel to Old servers with Xeon 4110 processors were replaced with new servers using the new Intel Xeon 5420+ processors. Results may vary. Performance measurements are based on SPECrate®2017_int_base published on spec.org as of March 28, 2023.

3 This is a preliminary estimate released in Intel's proxy statement. The final numbers will be made public in Intel's 2022-23 Corporate Responsibility Report, which will be released in the second half of 2023.

4 This is a preliminary estimate published in Intel's 10-K. The final numbers will be made public in Intel's 2022-23 Corporate Responsibility Report, which will be released in the second half of 2023.

5 Based on average U.S. household energy use data published by the U.S. Energy Information Administration.

6 See 4th Generation Intel® Xeon® Scalable Processor Announcement E1. Results may vary.

7 See: 4th Generation Intel Xeon Scalable Processor Announcement E6. Results may vary.

Previous article:Avant showcases latest solutions to embrace circular economy at Chinaplas 2023

Next article:Infineon drives decarbonization and digitalization with innovative semiconductor solutions at PCIM Europe 2023

Recommended ReadingLatest update time:2024-11-23 11:27

- Popular Resources

- Popular amplifiers

-

Microcomputer Principles and Interface Technology 3rd Edition (Zhou Mingde, Zhang Xiaoxia, Lan Fangpeng)

Microcomputer Principles and Interface Technology 3rd Edition (Zhou Mingde, Zhang Xiaoxia, Lan Fangpeng) -

Microcomputer Principles and Interface Technology Examples and Exercises (Kong Qingyun, Qin Xiaohong)

Microcomputer Principles and Interface Technology Examples and Exercises (Kong Qingyun, Qin Xiaohong) -

Design and application of autonomous driving system (Yu Guizhen, Zhou Bin, Wang Yang, Zhou Yiwei)

Design and application of autonomous driving system (Yu Guizhen, Zhou Bin, Wang Yang, Zhou Yiwei) -

x86 Assembly Language: From Real Mode to Protected Mode (2nd Edition)

x86 Assembly Language: From Real Mode to Protected Mode (2nd Edition)

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- STMicroelectronics IO-Link Actuator Board Brings Turnkey Reference Design to Industrial Monitoring and Equipment Manufacturers

- SABIC further deepens strategic partnership with Boao Forum for Asia

- Using 3.3V CAN transceivers to achieve reliable data transmission in industrial systems

- Nidec Precision Testing Technology will be exhibited at SEMICON Japan 2024

- HARTING and TTI announce strategic partnership now extended to Asia

- Samtec Connector Science | Connecting Artificial Intelligence in Smart Factories

- Advantech and Innodisk collaborate to unlock AMR vision capabilities with AFE-R360 MIPI camera module

- Laird Thermal Systems Announces New Line of Micro-Thermoelectric Coolers for Next-Generation Optoelectronic Devices

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- The clock signal is followed by an inverter.

- Some common IC integrated circuit quality judgment methods

- EEWORLD University Hall----Live Replay: TI Wireless Product Update: Wi-Sun Standard Helps Smart City Construction

- TI automotive solution puzzle, do you dare to challenge it?

- PIC12Cxxx series microcontroller selection (I)

- American semiconductor company recruits FAE- Chongqing, please enter for details.

- Summary of pull-up resistor and pull-down resistor

- [Fifth Batch of Shortlist] GigaDevice GD32L233 Review Event

- [SAMR21 new gameplay] 8. Serial communication-1

- Design of wireless data transmission transmitter based on PIC

Microcomputer Principles and Interface Technology 3rd Edition (Zhou Mingde, Zhang Xiaoxia, Lan Fangpeng)

Microcomputer Principles and Interface Technology 3rd Edition (Zhou Mingde, Zhang Xiaoxia, Lan Fangpeng)

京公网安备 11010802033920号

京公网安备 11010802033920号