Photovoltaic power supply is one of the most mainstream energy sources for outdoor equipment. The monitoring and control of solar panels and batteries require professional design. The photovoltaic power supply manager solution launched by Junlong Technology can improve power supply stability, extend battery life, and increase energy conversion efficiency. This article introduces the working principle and functional parameters of the manager module product, designs a complete and referenceable photovoltaic power supply system demonstration board, and conducts actual working conditions testing. This module product allows users to more easily build high-quality photovoltaic power supply solutions. Its real-time parameter monitoring output, battery health analysis, automatic path management and other functions make it bound to become an important cornerstone of the intelligence of photovoltaic power supply equipment.

The best choice for future energy

Photovoltaic power supply means that the sun directly irradiates solar panels to generate electricity. Compared with other ways of generating electricity, it is the most accessible clean energy. With the increasing awareness of energy conservation and emission reduction in the whole society in the new era, photovoltaic power supply, a long-established technology, has been re-emphasized.

As the intelligence level and deployment scale of contemporary industry have increased significantly, more and more instruments and equipment are deployed outdoors. The installation location of this kind of equipment is often remote and uncertain, and its power supply method is one of the very important design considerations, such as environmental monitoring instruments, remote sensing systems, highway equipment, etc. In the current design of such products, solar power supply has become a popular feature.

As the most important or even the only source of power supply for these instruments and equipment, the photovoltaic power supply system's stability and lifespan directly determine whether the instruments and equipment can work reliably for a long time. Junlong Technology has launched module products suitable for photovoltaic power supply systems, adding a "smart brain" to photovoltaic power supply, making it easy to deploy high-quality photovoltaic power supply solutions.

Difficulties in designing photovoltaic power supply

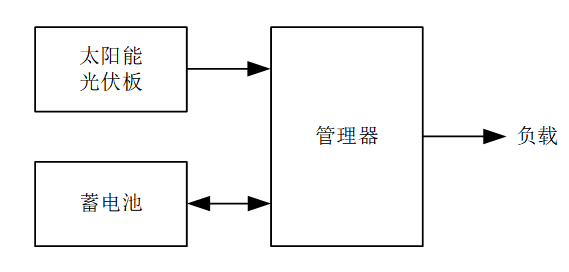

Photovoltaic power supply is a complete circuit system, including solar panels, batteries, managers and other parts, as shown in Figure 1. Among them, the manager is the core that determines the efficient and stable operation of the system. It is responsible for controlling the energy export of the solar panels throughout the process, and monitoring the charge and discharge of the battery. For the more sophisticated photovoltaic power supply manager, this control process needs to be dynamically combined with the load situation. adjustment to achieve the purpose of improving the energy utilization efficiency of the system.

Figure 1 Components of photovoltaic power supply system

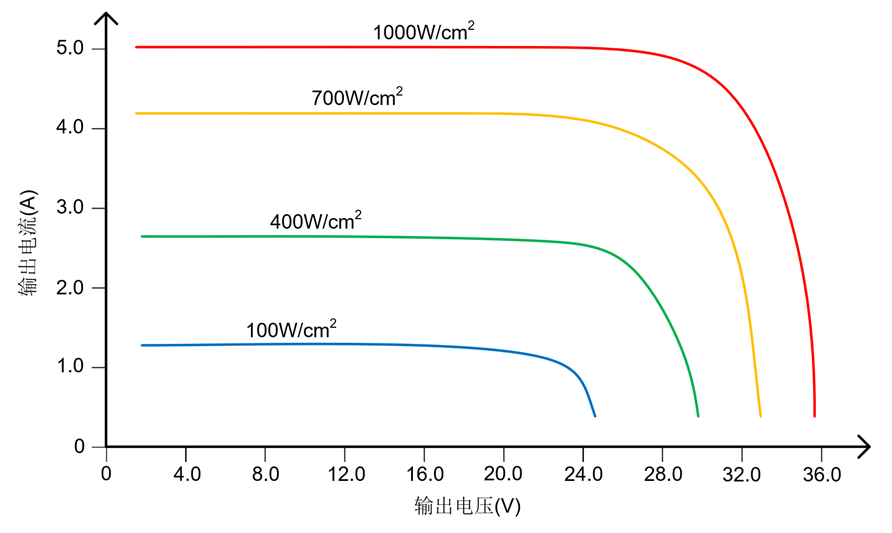

Although the photovoltaic power supply system has a simple structure, there are technical difficulties in operating and controlling each component. For solar photovoltaic panels, the main component is specially treated monocrystalline or polycrystalline silicon. For the output volt-ampere characteristic curve of the photovoltaic panel, its output power is directly related to the light intensity and has a maximum value, so it is not a single constant voltage. source or constant current source. When the light intensity is sufficient, the increase in the output current has basically no effect on the voltage amplitude; when the light intensity is weak, the change in the output current will significantly affect the output voltage.

Figure 2 is the volt-ampere curve of a certain model of 150W photovoltaic panel. The four curves are the volt-ampere curve under different light intensities. From the perspective of the power of voltage multiplied by current, the turning point of the curve is the power peak. When the photovoltaic panel works at this point At this time, the utilization efficiency of solar energy is the highest. As the light intensity changes, the power peak point will shift, which requires the manager to determine and actively adjust to this operating point. This technology is called maximum power point tracking (MPPT).

Figure 2 Volt-ampere curve of a certain type of photovoltaic panel

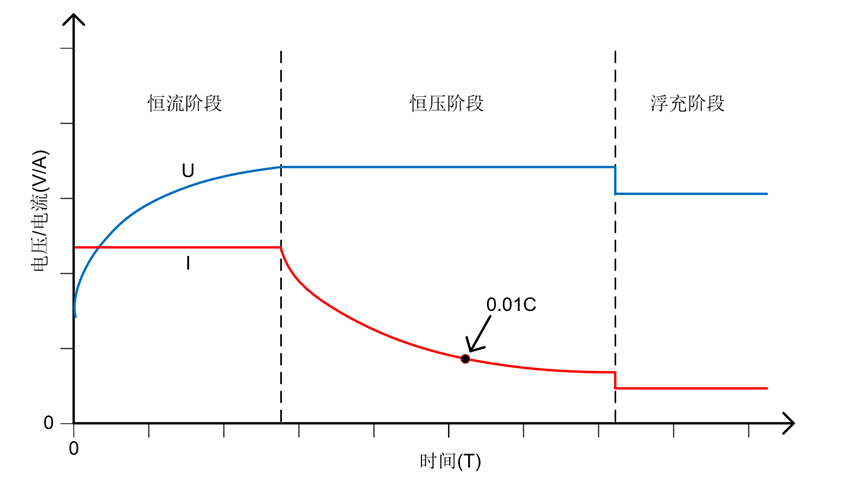

As for the battery part, lead-acid maintenance-free batteries are still the main type of instruments and equipment deployed outdoors for a long time. Due to electrochemical characteristics, the charging process of lead-acid batteries needs to be controlled regularly to extend its service life as much as possible.

Figure 3 shows the common "three-stage" charging control curve of lead-acid batteries. When the remaining battery power is very low, constant current charging is performed first. At this time, the battery voltage rises steadily; when the specified voltage is reached, constant voltage charging is performed. , at this time, the charging current of the battery will continue to decrease until the current drops to 0.01 times the maximum charging current value (0.01C), and it will enter the charging countdown stage; the charging duration below 0.01C is generally limited, and the countdown time After arriving, it will enter the constant pressure float charging stage. The entire control process above is completed by the manager. If the battery starts charging from a state in the middle of the curve, the manager should also accurately judge and execute it. Currently, lithium-ion polymer batteries, lithium iron phosphate batteries and other types of batteries are also used in the industry. These batteries also have their own characteristic charging control curves. You can also consult the technical staff of Junlong Technology for specific technologies.

Figure 3 Charging control curve of lead-acid battery

Smart brain simplified design

From the previous technical analysis, we can see the importance of the manager in the photovoltaic power supply system. A high-quality photovoltaic power supply manager can significantly improve the energy efficiency and continuous service life of the system. To this end, Junlong Technology has launched a highly integrated and intelligent manager module solution, providing a "smart brain" for the photovoltaic power supply system. The module model is MCUM4162-SLR, which has the following features:

Compatible with solar panels up to 36V

Supports batteries up to 33.6V

Maximum charging current 3.2A, charging efficiency over 95%

Automatically switch load power supply source (photovoltaic panel or battery)

Support MPPT to improve solar light efficiency

Battery health analysis and early warning function

Visual output of system operating status and abnormal alarms

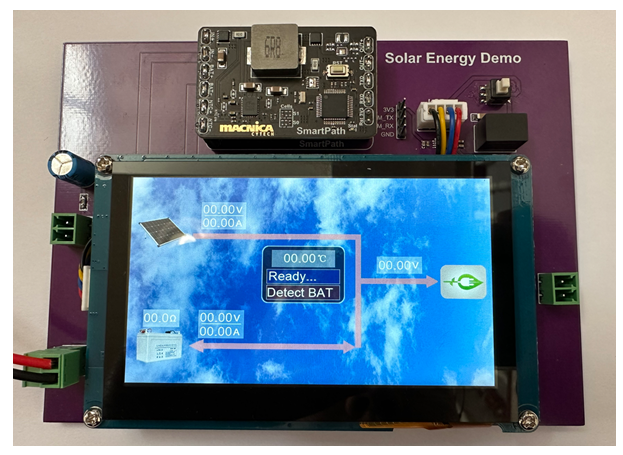

In order to facilitate product function display and users to quickly get started, Junlong Technology has designed a photovoltaic power supply system demonstration board. Figure 4 and Figure 5 show the structural block diagram and physical diagram of its lead-acid battery version. Among them, the core functional module MCUM4162-SLR is the manager in the photovoltaic power supply system. Due to its high degree of integration, peripherals can almost be directly connected to the manager module. The demonstration board shown in Figure 5 is equipped with a configuration display screen, and its display content is controlled by the MCU on the functional module. In this demonstration board, the display screen can display the output voltage and current of the photovoltaic panel, the real-time voltage and current of the battery, the voltage output to the load, battery impedance, board temperature, as well as various working status and alarm information. Comprehensive output information can help users understand the working status of each part of the photovoltaic power supply system and monitor its stability, power efficiency and lifespan.

Figure 4 Junlong Technology photovoltaic power supply demonstration board structure

Figure 5 Junlong Technology photovoltaic power supply demonstration board in action

The structure diagram of the photovoltaic power supply demonstration board shown in Figure 4 can be directly used for reference design by users. There are several design details that need to be paid attention to. At the access point of the photovoltaic panel, a series circuit of 150uF capacitor and 2.5 ohm resistor to ground is added. This is mainly used to impedance match the photovoltaic panel and give full play to the MPPT function of the manager module. In the photovoltaic panel output volt-ampere curve mentioned earlier, it can be divided into two parts: the front-end constant current and the back-end constant voltage. The photovoltaic panel in the constant voltage stage shows low impedance, while the constant current stage exhibits high impedance, which will lead to management The input impedance loop of the converter module is unstable, and the impedance can be stabilized through compensation of the resistor-capacitor series circuit.

For the matching display screen, users can also use MCU or other terminal forms instead. The information output of the MCUM4162-SLR module uses the TTL serial port form. The HMI serial port display used in this demonstration board has a built-in display control unit. Users also need to consider the display control function when designing the system, because the onboard MCU on the MCUM4162-SLR module is dedicated to photovoltaic control and can only Output module working parameter information. The power supply of the display screen is taken from the load end of the photovoltaic power supply system, which is stepped down by DCDC, and a switch is connected in series to turn off the screen in time to save power.

In addition, the module integrates automatic path management capabilities. As shown in Figure 6, solar photovoltaic panels can supply power to the load while charging the battery. Therefore, it can be understood that the load energy comes primarily from the photovoltaic panels. This can avoid the situation of the battery "charging and discharging at the same time" and prolong the Battery service life; when the photovoltaic panels are insufficient to support the power required for charging, the manager will automatically switch the load to the battery power supply path. For the timing of switching, the manager needs to comprehensively consider the load demand current, the voltage and current output by the photovoltaic panel, and the minimum starting threshold for charging. This is a dynamic and comprehensive decision-making process.

Previous article:Core Technology empowers China's new infrastructure and talks about the black technology behind energy storage

Next article:Advantech’s smart energy solutions accelerate the realization of carbon neutrality

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

- Focusing on promoting innovation and transformation, UHV field creates more possibilities in the era of clean energy

- Infineon Technologies Launches SECORA™ Pay Green, World’s First Contactless Payment Card Technology, Reducing Plastic Waste by Up to 100%

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- Finding hope in despair

- Please recommend a 48 to 12V DCDC step-down chip

- Happy Valley facility malfunctioned, many children were hanging upside down in the air~~

- [LAUNCHXL-CC2650] simple_peripheral routine analysis

- Is it a tax on IQ?

- CCS compilation error: unresolved symbols remain solution

- Fiber Optic Project Overview

- Bluetooth module problem

- Switching Power Supply Interest Group 13th Task

- Is the ST website down? Or is it crashing?

ST Power Management Guide

ST Power Management Guide

京公网安备 11010802033920号

京公网安备 11010802033920号