In 2022, under the dual stimulation of policy support and market demand, energy storage has suddenly become one of the hottest industries. The essence behind this is the continuous increase in the installed capacity of renewable energy . Unlike thermal power and other units that can actively control power generation, renewable energy power generation is affected by the natural environment, has strong uncertainty, and is even incompatible with the power grid. Therefore, it needs to be equipped with an energy storage system to solve the problems of consumption, peak shaving, Various issues such as frequency regulation and power grid stabilization.

According to data from the National Energy Administration, between 2016 and 2021, China's average wind and light curtailment rates have dropped from 17.0% and 10.3% to 3.1% and 2.0% respectively . In addition to power grid operation optimization, one of the reasons is technological progress. In addition, it is also inseparable from the development of energy storage. Moreover, Chen Yongchong, leader of the energy storage technology research group of the Institute of Electrical Engineering of the Chinese Academy of Sciences, recently stated that although my country’s energy storage installed capacity ranks first in the world, the ratio of energy storage to wind power and photovoltaic new energy installed capacity (referred to as the “new storage ratio”) is less than 7 %; relatively speaking, the average storage-to-new ratio in other countries and regions has reached 15.8%. With the rapid increase in the scale of new energy power generation, there is still a lot of room for growth in my country's new energy storage ratio.

In terms of energy storage technology, although pumped hydropower storage currently occupies the absolute dominant market, this century-old technology is giving way to electrochemical energy storage (BESS) that uses batteries as buffer storage media. The latter Because it is not restricted by natural conditions and has the characteristics of rapid response and flexible deployment, it is fully consistent with the characteristics of renewable energy with small capacity, dispersed layout and large quantity. It can be deployed flexibly on the household side, industrial and commercial side and grid side. According to statistical data from the "2022 Energy Storage Industry Application Research Report" released by the Energy Storage Application Branch of the China Chemical and Physical Power Supply Industry Association, there will be 146 new energy storage projects in China in 2021, and there will be 131 electrochemical energy storage projects. Among them, there are 120 lithium-ion battery energy storage projects. At the same time, in addition to large-scale projects, more small and micro energy storage stations represented by industrial, commercial and household applications are blooming.

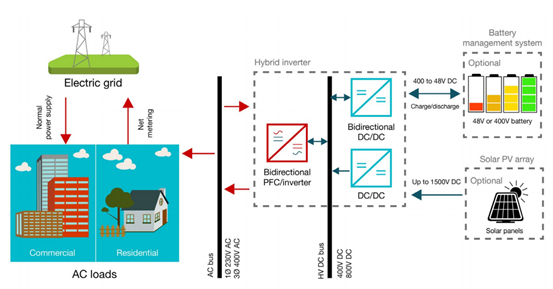

Although in the long run, the development of BESS is the general trend, at this stage, issues such as cost, safety, service life, and environmental protection still hinder the industry to a certain extent, and technological development has become a very important factor. In short, BESS is the power conversion between DC and AC, battery charging and discharging, and the control process of the entire industrial system. Naturally, it is inseparable from power electronics technology to ensure the safety and high efficiency of the energy storage system. Therefore, generally speaking, a typical BESS contains the following parts: PCS (power conversion system) is responsible for power conversion between the battery DC link and the inverter AC bus (i.e. battery and grid), BMS (battery Management system) is responsible for monitoring key information of the battery, and EMS (energy management system) is responsible for operating and controlling the entire system.

No matter any part of the energy storage system, it is inseparable from the support of chips. This article will use specific products and solutions to let everyone understand the key components of the BESS system and how to overcome the challenges faced. In this field, Texas Instruments (TI), one of the major suppliers of power electronics, has decades of relevant technology accumulation. At the same time, TI also has rich product and system experience in battery management and industrial control, and can build a complete system for the entire ESS system. signal and energy transfer links, so this article selects several representative products and solutions from TI.

Bidirectional power conversion system

In the past, when there was no supporting energy storage, the power flow from renewable energy sources was often transmitted directly to the grid side in one direction. Adding an energy storage system to this architecture makes it obvious that a two-way system is better than two one-way systems. Therefore, bidirectional DC/DC charge and discharge management needs to be added to the energy storage side. At the same time, the AC/DC side also needs to be changed to a bidirectional architecture and integrate PFC (power factor correction) and inverter. This more flexible two-way structure helps achieve better peak shaving and valley filling, storing electric energy when the electricity price is cheap or generating a lot of electricity, and releasing it in time when there is demand.

Generally speaking, this bidirectional architecture means two independent conversion systems, including power, control, protection, etc. , which brings higher system cost, more complex layout and wiring, and larger volume.

Bidirectional PFC and inverter stage

Since the power devices in the topology are essentially the same, the two can be combined to achieve high efficiency and small size of the system. Among them, the bidirectional DC/DC power stage is specially built for energy storage inverters. The common topologies of bidirectional DC/DC power stage are CLLLC and DAB. For the off-grid/grid-connected bidirectional inverter/PFC power stage, no special topology is required to implement it, because the inverter power stages commonly used in standard string inverters, such as two-stage H-bridge, HERIC, three-level TNPC, three-level NPC and three-level ANPC can all achieve bidirectional conversion.

These complex topologies bring many challenges to power conversion and control. At the same time, for high-power inverters, there may be several parallel connections, so synchronization requirements with each other and with the grid are also required.

At the same time, in order to achieve higher conversion efficiency and energy storage density, energy storage systems are increasingly introducing wide bandgap semiconductors as their power devices. Compared with traditional silicon devices, wide bandgap semiconductors can achieve higher switching frequencies. , thereby improving conversion efficiency and reducing size, but this higher switching frequency also brings challenges from driver design to layout and wiring, EMI, thermal management, etc.

Efficiency, volume and cost are important, but reliability and safety always come first. For example, a grid-connected bidirectional inverter needs to have detection and isolation functions. When the power grid fails (such as power outage, power outage, overvoltage, etc.), it should be disconnected in time.

Just like the above challenges, no matter what type of power topology, design is never easy. Therefore, the best solution is to choose an optimized reference design solution and a one-stop supplier as much as possible. TI provides a variety of topology reference solutions to meet the needs of various power conversion systems.

TIDA-010210 Reference Design

Taking TI's GaN-based 11kW bidirectional three-phase ANPC reference design TIDA-010210 as an example, this reference design provides a design template for implementing a three-level three-phase ANPC inverter power stage based on gallium nitride (GaN). The use of fast-switching power devices enables higher switching frequencies of 100kHz, which not only reduces the size of the filter's magnetic components, but also increases the power density of the power stage. The multi-level topology allows the use of 600V rated power devices at higher DC bus voltages up to 1000V, which is not possible in other topologies. At the same time, lower switching voltage stress can reduce switching losses, resulting in a peak efficiency of 98.5%, and also improve system reliability.

The solution integrates a number of TI's star products, including C2000 32-bit MCU, GaN FET with integrated driver, protection and temperature reporting, gate drivers, switching converters and other power products, as well as digital isolators, amplifiers and other signal chain products.

Multilevel topologies allow the use of low-voltage switching devices, but also mean that more switches need to be driven and overvoltages need to be avoided even during abnormal operation. In this reference design, TI uses only one C2000 to control 18 power components under limited PWM, and implements hardware-based chain protection through the integrated CLB, eliminating the need for an external FPGA or CPLD. And only software control is needed to realize the reversing function.

High reliability battery management system

Similar to the power conversion system, the battery management system must first ensure sufficient safety and reliability, and then optimize it in terms of efficiency, volume and cost, and BMS is the most important system to ensure battery safety.

Typical energy storage BMS systems can be roughly divided into BMU, BDU and BCU . The BMU implements independent battery information collection, the BDU manages the battery cluster, and the BCU is responsible for the overall control and communication.

Since the battery management system pays more attention to battery charge and discharge management, it needs to collect various types of information in detail, including battery information storage, collection, equalization control, charge and discharge management, etc. Therefore, a high-performance AFE is the key to achieving a high-level BMS and should solve customer pain points in terms of accuracy, robustness, safety, and system cost.

Previous article:Solvay adds sustainable raw materials to ReCycle portfolio of specialty polymers

Next article:Junlong Technology recently launched the MCUM4162-SLR module - equip your photovoltaic power supply with a "smart brain"

- Popular Resources

- Popular amplifiers

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- STMicroelectronics IO-Link Actuator Board Brings Turnkey Reference Design to Industrial Monitoring and Equipment Manufacturers

- SABIC further deepens strategic partnership with Boao Forum for Asia

- Using 3.3V CAN transceivers to achieve reliable data transmission in industrial systems

- Nidec Precision Testing Technology will be exhibited at SEMICON Japan 2024

- HARTING and TTI announce strategic partnership now extended to Asia

- Samtec Connector Science | Connecting Artificial Intelligence in Smart Factories

- Advantech and Innodisk collaborate to unlock AMR vision capabilities with AFE-R360 MIPI camera module

- Laird Thermal Systems Announces New Line of Micro-Thermoelectric Coolers for Next-Generation Optoelectronic Devices

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- RAQ #223: How to measure and determine soft-start timing without a soft-start equation?

- RAQ #223: How to measure and determine soft-start timing without a soft-start equation?

- GigaDevice's full range of automotive-grade SPI NOR Flash GD25/55 wins ISO 26262 ASIL D functional safety certification

- GigaDevice's full range of automotive-grade SPI NOR Flash GD25/55 wins ISO 26262 ASIL D functional safety certification

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- Infineon Technologies Launches ModusToolbox™ Motor Kit to Simplify Motor Control Development

- STMicroelectronics IO-Link Actuator Board Brings Turnkey Reference Design to Industrial Monitoring and Equipment Manufacturers

- Melexis uses coreless technology to reduce the size of current sensing devices

- KiCAD 6 is about to be released, and a great guy has made a comparison with 5

- Overview of the top ten most popular majors in 2006

- Testing of piezoelectric ceramics

- Op amp input overvoltage protection: clamping vs. integration

- 【NXP Rapid IoT Review】 The first test program

- Buzzer, DC motor and stepper motor interface for TMS320C28x series TMS320F2837x development board

- 50A μModule regulator achieves cool operation

- Embedded learning exchange group. 11048324

- How to Reduce Ripple in a PWM DAC in a Microprocessor

- A certain unit of the Second Artillery Corps has successfully developed a new type of missile simulation training equipment

Multi-port and shared memory architecture for high-performance ADAS SoCs

Multi-port and shared memory architecture for high-performance ADAS SoCs

京公网安备 11010802033920号

京公网安备 11010802033920号