Mr. Wang Daheng, a famous scientist and academician of the Chinese Academy of Sciences and the Chinese Academy of Engineering, once pointed out: "Machines are tools for transforming the world, and instruments are tools for understanding the world." Instruments are "multipliers" of industrial production, "pioneers" of scientific research, "combat effectiveness" in the military, and "materialized judges" of modern social activities. It goes without saying that instruments play a very important role in promoting the development of science and technology and the national economy in today's era.

For industrial applications, instruments are the "five organs" of all equipment and transmission channels, and are one of the most important components of modern factory construction. The accurate data provided by instruments can help us know the status of industrial systems in a more timely manner.

So what is the current status of the technical indicators, evolution, and application of pressure sensors in industrial instruments? We will analyze it in detail here. I believe that through this understanding, you will have a better understanding and knowledge of the application of pressure sensors in the field of instrumentation.

The development trend of pressure sensors in industrial instrumentation industry

The most important development trend of pressure sensors is to meet the requirements of continuous development and innovation in the field of industrial instrumentation. High precision, miniaturization, intelligence, and dataization are the development trends of instrumentation. With the evolution of the complexity of the overall industrial system, more and more instruments are required to have higher precision to accurately measure and obtain various data and information of the overall system; secondly, due to the limitations of on-site location and weight, products are increasingly required to be miniaturized and miniaturized; thirdly, with the rise of the Internet of Things, 5G technology and other networking technologies, instruments need to collect more data and information, which not only requires more overall collection quantity, but also requires more accurate and diverse data or information for each node.

Pressure sensors can be divided into metal strain gauge pressure sensors, semiconductor strain gauge pressure sensors, silicon piezoresistive pressure sensors, inductive pressure sensors, capacitive pressure sensors, resonant pressure sensors, etc. according to their different working principles.

Among them, the most widely used is the silicon resistive pressure sensor, whose main principle is to use the piezoresistive effect of silicon to convert the change of the inductive force on the mechanical component into the change of the resistance. The change of resistance value of this silicon sensor when subjected to force is usually small. Generally, this silicon strain gauge is made into a Wheatstone bridge, and amplified by a subsequent instrument amplifier, and then transmitted to the back-end processing circuit.

How to choose the right pressure sensor

There are many types of industrial instruments and meters, and each type of product has completely different requirements for pressure sensors based on its specific characteristics and application areas.

When choosing a sensor, it is a better choice to choose a supplier with a wide range of products. A richer range of products means more choices and solutions for customers . As one of the world's leading connector and sensor companies, TE Connectivity (TE) continues to provide the industry with a wide range of product portfolios. It manufactures pressure sensors and transmitters for equipment in the fields of industry, test and measurement, automobiles, and medical, and provides a variety of materials, output methods, sensor technologies, and third-party certifications to meet customers' various requirements for liquid or gas pressure measurement.

TE's hundreds of pressure sensors have their own characteristics and can cover more application areas. They provide pressure sensors from sensing elements to system packaging, from board-mounted pressure elements to pressure transmitters with amplified output and complete packaging. Based on semiconductor micromachining (MEMS) technology and silicon strain gauge technology, TE's products can measure various pressures from a few inches of water column (<5mbar) to 100K psi (7K bar). It creates reliable and cost-effective pressure sensor solutions for general industrial applications, medical, HVACR, off-road vehicles/heavy equipment, altimeters/navigation systems and other applications.

How pressure sensors meet instrumentation needs

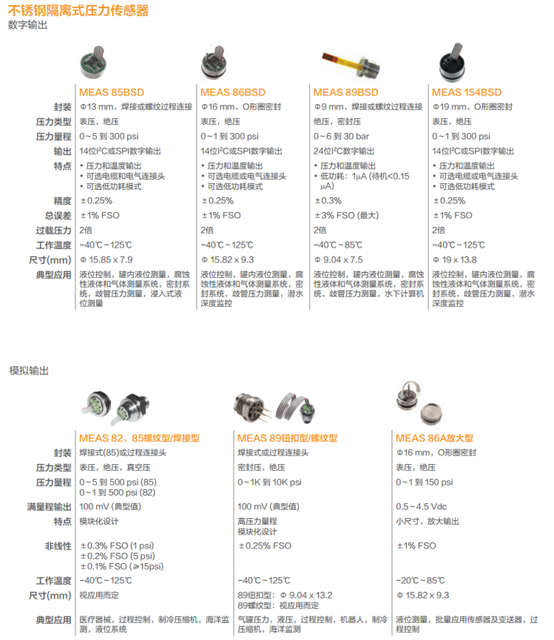

Taking TE stainless steel isolated pressure sensor as an example, we explain how pressure sensors meet the needs of the development of industrial instrumentation.

First of all, in terms of parameters, this series of products has a wide range of types, ranging from 0-1 PSI to hundreds or even tens of thousands of PSI, which can cover the pressure measurement of a variety of liquids and gases. At the same time, a higher range also means that the device has higher reliability.

Secondly, the hysteresis and repeatability reach ±0.02%, the thermal hysteresis reaches ±05%, the long-term stability is ±01%, and the accuracy can be guaranteed within a few thousandths, which provides reliable guarantee for accurate measurement and avoids the accuracy of the entire system being affected by the error at the acquisition end. This has outstanding advantages in the semiconductor industry and the precision gas flow meter industry.

Third, a wider temperature compensation range (-20℃ to 85℃) and operating temperature range (-40℃ to 125℃). Since instruments need to face complex on-site environments and maintain stable working conditions at low and high temperatures, the reliability and adaptability of the products can be ensured. Even in the cold Northeast region or the hot steelmaking site, the sensors can work normally.

Fourth, it supports digital and analog signal output. Analog sensors and digital sensors are very different in terms of the technology, interface, output signal, etc., so they can be selected according to customer needs. At the same time, in terms of digital interface, TE also provides different selection modes including SPI, I2C, and even wireless transmission systems. Users can choose according to the system function of reading and processing signals.

Fourth, it supports a variety of connection methods to meet the different application requirements of customers. Although TE provides standard configurations, special structures can also be customized according to the special requirements of users. Threaded connections can be male and female, and can be designed with conical seals, O-rings or metal face-to-face seals.

Fifth, we provide a flat diaphragm design. In certain medical, chemical, food processing and other instruments, there must be no cavities or gaps around the sensor diaphragm that is in contact with the medium to prevent foreign matter from remaining. Our flat diaphragm pressure sensors can meet a variety of demanding user applications.

Sixth, there are many types of materials for customers to choose from. TE uses pressure chambers and joints made of a variety of materials to meet different test environments, including 17-4PH stainless steel, 316L, alloy 718, alloy C276 and titanium alloy. For example, 17-4PH stainless steel is suitable for most gases and special liquids such as hydraulic oil, air (nitrogen, oxygen, etc.), natural gas, Freon, paint, steam, plastic molding, diesel, carbon dioxide, etc. 316 L stainless steel is suitable for applications such as hydrogen, chlorinated water, ammonia refrigerant, petroleum products (crude oil or refined oil).

Everything is application-oriented, which is the purpose of TE product development.

By covering standards such as different measuring ranges, different resolutions, different packages, and different interfaces, TE has built a broad product line portfolio to meet the needs of different application scenarios.

Star product interpretation

The 85BSD series pressure sensors are widely used by TE and the industry. They have distinct product features and advantages and are widely used in various industrial instruments and meter fields.

85BSD Pressure Sensor

The 85BSD pressure sensor product is a silicon piezoresistive pressure sensor with a compact shape and good media compatibility, packaged in a 316L stainless steel housing. This 14-bit digital pressure sensor supports I2C and SPI output protocols, with a power supply voltage of 3.3 or 5.0Vdc, and can be welded or directly connected to the process through threads. The sensor transfers pressure from the 316L stainless steel isolation diaphragm to the sensing element through silicone oil. The 85BSD pressure sensor product can be widely designed and applied in high-performance, low-pressure range applications. Due to the use of digital processing technology, TE has specially customized ASIC chips to achieve temperature compensation and deviation correction of the sensor, and can provide two output modes of 10~90% range or 5~95% range to facilitate data collection and processing for different customers.

In addition to achieving industrial automation by providing sensors that match instruments and meters, TE also uses its strong system integration capabilities to launch a variety of transmitters and wireless modules that can be directly used in industrial automation sites.

M3200 Series Pressure Transmitter

TE's M3200 pressure transmitter has analog or digital output and is suitable for measuring liquid or gas pressure, as well as special media such as sewage, steam, and mildly corrosive liquids. The pressure chamber of the M3200 pressure transmitter is made of 17-4PH stainless steel. TE's proprietary micro-melting technology is derived from demanding aerospace applications. This technology uses high-temperature micro-melting glass to adhere micro-machined piezoresistive silicon strain gauges to stainless steel isolation diaphragms. This solution provides very high long-term stability while reliably and efficiently obtaining media compatibility, avoiding the PN junction effect that occurs in pressure transmitters during traditional micro-machining manufacturing processes.

This product is particularly suitable for industrial and commercial customers with medium and large volume requirements. The optional pressure range is between 0-100 and 5,000 PSI, supporting a variety of accuracy options. It provides five standard analog output signals as well as 14-bit digital pressure and 11-bit digital temperature output signals. The higher integration level means that customers do not need to design additional interface circuits and temperature sensors. In addition, it can also directly provide a 4-20 mA output signal, making it convenient for customers to access traditional industrial systems.

M5600 Wireless Pressure Sensor

The M5600 pressure sensor is a pressure sensor that uses micro-melting technology and modular wireless signals. It uses a stainless steel and polycarbonate shell packaging structure. This 24-bit ADC wireless digital output sensor eliminates the hard wiring of the signal and can provide remote process control and monitoring through Bluetooth 4.0 technology. This series of products is suitable for measuring liquids and gases, as well as special media such as sewage, steam and mildly corrosive liquids. The isolation material of the pressure port is 17-4PH or 316L stainless steel, and there is no seal, weld or any organic material in the contact part between the sensor and the pressure medium, so it has excellent durability and reliability. The M5600 pressure sensor has good wind and rain resistance, which is better than the latest heavy industry CE standards. This wireless pressure sensor is particularly suitable for medium and large-volume customers. Because it is a wireless Bluetooth connection, users can view data directly on the mobile phone APP, which is very in line with the development trend of future smart factories.

TE's excellent sensor family

As a leading company in the field of industrial sensors, in addition to a rich range of pressure sensor products, TE also provides more sensor varieties, covering pressure, temperature, photoelectric, electromagnetic and other technologies, which are used in many fields including automobiles, industry, medical care, electrical appliances, aerospace and so on.

The biggest competitive advantage of TE products and TE's purpose is to provide the most suitable products for different application scenarios of our customers by adopting different sensor combinations and different sensor characteristics, and to provide and support customized and modular products and services.

Previous article:Pressure interface chip MLX90328 DBA version calibration method

Next article:What are the requirements of the oil industry for pressure sensors?

- Popular Resources

- Popular amplifiers

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Milestone! SmartSens CMOS image sensor chip shipments exceed 100 million units in a single month!

- Taishi Micro released the ultra-high integration automotive touch chip TCAE10

- The first of its kind in the world: a high-spectral real-time imaging device with 100 channels and 1 million pixels independently developed by Chinese scientists

- Melexis Launches Breakthrough Arcminaxis™ Position Sensing Technology and Products for Robotic Joints

- ams and OSRAM held a roundtable forum at the China Development Center: Close to local customer needs, leading the new direction of the intelligent era

- Optimizing Vision System Power Consumption Using Wake-on-Motion

- Infineon Technologies Expands Leading REAL3™ Time-of-Flight Portfolio with New Automotive-Qualified Laser Driver IC

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Three steps to govern hybrid multicloud environments

- Three steps to govern hybrid multicloud environments

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Analysis of the design steps of RS-485 bus interface circuit

-

[NXP Rapid IoT Review] +

NXP Rapid IoT Online IDE Air Quality Test - How to remotely control a two-wheeled balancing vehicle via the Internet?

- How to get the most out of your low noise amplifier solution?

- Android4.4.2 source code compilation-iMX6Q/D core board-non-device tree source code

- 【GD32E503 Review】 Unboxing and Powering on the Machine

- JHIHAI APM32E103VET6 Review: External Interrupt (EINT)

- PYPL Programming Language Popularity Index, September 2022

- I don't quite understand this thermal imager resolution comparison chart

- [TI recommended course] #Amplifier design in test and measurement#

HCPL-7840#300E

HCPL-7840#300E

京公网安备 11010802033920号

京公网安备 11010802033920号