TechInsights discusses Apple smart watch metal case battery - a novel design suitable for portable and wearable electronics

TechInsights’ analysis report link for Desay A2663 Metal Can Battery Report

Among consumer electronics, wearable devices are one of the most form-constrained categories. Manufacturers are trying to achieve advanced functionality and increase processing and energy storage levels in small, lightweight devices. Wearable devices must withstand frequent charging and operate safely over the long term, regardless of temperature changes, vibrations and shocks. Based on our product-level disassembly results analysis (Tear Down), TechInsights analyzed various wearable products and found that in terms of appearance and size, a considerable number of batteries use pouch cells. And the Apple Watch is in a league of its own. In 2019, Apple Watch 5 series smart watches (including 40 mm and 44 mm models) were released. TechInsights discovered a metal-cased battery for the first time in the 40 mm model of the series. In order to further study the related applications of metal cases, we decided to characterize the metal case batteries by analyzing the Apple Watch 7 series smartwatch (41 mm) to explore the reasons for using metal cases instead of soft bags.

More details and analysis on this battery can be found in the "Desay A2663 Metal Case Battery (Apple Watch Series 7 - 41 mm) Overview" report. The report is available by subscribing to the TechInsights Rechargeable Battery Brief.

Battery appearance overview:

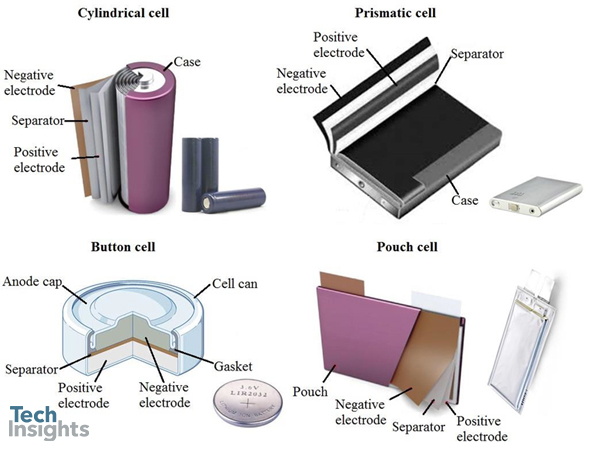

TechInsights found that the basic structure of most lithium-ion batteries consists of four parts: 1) cathode material coated on aluminum foil (consumer electronics usually use LiCoO2), 2) as anode material coated on copper foil layered graphite, 3) an ion-conducting electrolyte (usually a liquid) made from a solution of lithium salt dissolved in an organic solvent (usually a carbonate), and 4) made from layers of polyethylene and polypropylene and set in An insulating separator between the anode and cathode to avoid short circuit. Based on these components, there are currently four main lithium-ion battery configurations (form factors) on the market, namely cylindrical batteries, prismatic batteries, pouch batteries and button batteries, as shown in the figure below.

Figure 1: The most common lithium-ion battery types [1]

Popularity of soft pack batteries

Pouch batteries are the most common form factor in consumer electronics because they can be customized into different sizes to maximize the use of available space in the device and achieve 90%-95% packaging efficiency.

In pouch cell designs, stacks of anodes, cathodes, and separators are encased in a soft casing. Battery casings are often made from aluminum foil laminated on both sides with organic polymers. The battery casing's sealed multi-laminate prevents the lithium battery's electrode components from reacting with moisture, oxygen and other contaminants from the outside. The sealed multilayer board also prevents or reduces any leakage of electrolyte, thereby avoiding damage to other components of the portable electronic device.

Soft pack batteries and safety

Minimum critical distances are set for pouch battery enclosures in many devices. The minimum critical distance refers to the distance between the edge of the battery casing (or the edge of the seal in some embodiments) and its surrounding components. If the bag width is less than the minimum critical distance, tears or ruptures may occur, and the seal may be susceptible to failure, especially if it is subject to significant impact or expansion during cycling.

Introduction of metal case batteries

As mentioned earlier, in 2019, TechInsights encountered a metal-cased battery in an Apple Watch for the first time. Further investigation revealed that Apple applied for a patent for a metal-cased battery in the same year, which is still pending as of this writing. The patent describes how it is an "improved battery that reduces the space between the battery and electronic components." The patent details how to optimize the available space in an electronic device without requiring spacing between the battery housing and other components in the electronic device. In some designs, the metal casing can be connected to a common ground to allow other components to contact the battery casing without causing a short circuit. Additionally, metal casings can be used as structural elements in electronic devices. For example, a bracket can be attached to a metal housing, or a flange between two housing pieces can serve as a connection point.

Reverse engineering the Apple Watch Series 7 smartwatch (41mm) and its metal case battery

Here at TechInsights, we opened an Apple Watch Series 7 smartwatch (41mm) in order to describe its metal-cased battery. Figure 2 shows the inside of the device and its battery with the display removed.

Figure 2: Disassembly view of Apple Smartwatch Series 7 (41mm) with the display removed.

Table 1 compares the Apple Watch Series 7 smartwatch (41mm) battery with a larger version (both batteries are produced by Desai Group). Results showed that the metal shell design reduced coverage area by 10% without compromising area capacity (capacity per unit area). However, its energy density (energy per unit volume) is 19% lower than that of the larger watch. In the Apple Watch 7 series smartwatch (41 mm), the battery aspect ratio is 0.193, which is significantly larger than the 45 mm version. After looking at the real thing, we confirmed that the metal case was connected to a common ground point to allow other components to contact the battery case without causing a short circuit.

Table 1: Comparison of Apple Watch 7 Series smartwatch (41 mm) and (45 mm) batteries

Battery Characteristics Analysis

To further analyze the battery, the battery pack of the Apple Watch Series 7 smartwatch (41 mm) was removed and tested using Differential Capacity Analysis (DCA) at C/20. To compare the results to its larger siblings, TechInsights normalized the dq/dV values based on battery capacity (dq/dV divided by battery capacity). As shown in Figure 3, the two batteries have similar chemistry, with lithium cobalt oxide as the cathode and graphite as the anode.

Figure 3: Differential capacitance curve of the battery of the Apple Watch Series 7 smartwatch (41 mm) compared to larger sizes.

The impedance and internal resistance of the Apple Watch 7 series smartwatch (41 mm) battery were analyzed using the electrochemical impedance method (EIS) under different states of charge (SOC). EIS measurements were performed in the frequency range from 3 kHz to 50 mHz by applying a sinusoidal signal with an amplitude of 5 mV. Figure 4 gives the corresponding results in the form of a Nyquist plot. Comparison of different spectra shows that they have similar trends. Generally speaking, each spectrum consists of two semicircles for medium and high frequencies, and then a 45° line for the low frequencies. The intercept of the real and imaginary axes means that the total resistance is equal to 110mΩ. The first semicircle represents the solid electrolyte interface of the battery, while the second semicircle represents the electrochemical reactions at the anode and cathode. The 45◦ line corresponds to the diffusion of lithium ions. The sum of the diameters of each semicircle represents the resistance to electrochemical phenomena. For a fully discharged battery, this value is ~0.4Ω; as the battery charges, the charging resistance drops by 35%.

Figure 4: Nyquist plots of the Apple Watch Series 7 smartwatch (41mm) battery at 3%, 25%, 50%, 75% and 100% charge states.

Normally, the smaller the capacity, the higher the internal resistance of the battery. However, when it comes to the batteries in the Apple Watch 7 series smartwatches, the smaller version has a similar impedance compared to the larger version. (Figure 5)

Figure 5: Nyquist plots of Apple Watch 7 Series smartwatch (41mm and 44mm) batteries at SOC of 3% and 75%.

Battery structural and physical analysis

To gain a deeper understanding of the battery's design and chemistry, we took it apart to understand the structure and stacked layers of the battery inside the box. Figure 6 shows the battery with the metal case removed. The anode current collector is welded to the nickel tab (anode electrode), and the nickel tab is welded to the metal shell to form a common ground for the entire metal shell. The cathode current collector is connected to the aluminum tab. However, the plastic seal prevents the cathode connector from contacting the metal, causing a short circuit, as shown in the picture. To prevent any possible direct contact between the pole core and the tab, a polymer plate is incorporated into the metal soft case as shown in the picture.

Figure 6: Disassembly view of the Apple Watch 7 series smart watch (41mm) battery after opening the metal case.

Electrode structure analysis

Figure 7 shows a SEM (scanning electron microscope) cross-sectional micrograph of the electrode. Energy dispersive X-ray spectroscopy (EDX) analysis proved that the chemical composition of the battery is mainly based on cobalt oxide-based cathodes and graphite-based anodes. The thickness of the electroactive material and the relatively thin current collector provide optimal conditions for maximizing energy density without compromising the cell's power-handling capabilities.

Figure 7: Detailed battery stack – SEM cross-section of an Apple Watch Series 7 smartwatch (41mm) battery.

The separator of this battery is an organic polymer coated with a ceramic layer on both sides. Desai used a special ceramic to improve the safety of the battery in the event of thermal runaway.

Figure 8: SEM cross-sectional view of the battery metal case of the Apple Watch 7 series smart watch (41mm).

Battery size discussion

One of the goals of metal case battery sizing is to reduce the size of the battery. This begs the question, what if the pole core (Figure 6) was housed in a traditional polymer housing? Polymer cases are typically thicker, ~100μm thick, adding 200μm (0.2mm) to the total cell thickness in terms of width, length and height. Secondly, in the case of polymer pouch batteries, it is not possible to connect the entire body and other electronic components of the device within the case to a common ground, thus losing other safety features. In addition, the expansion of the battery cannot be controlled because this design allows the metal case to expand in a controlled manner, as shown in the report [2].

Previous article:Lenovo/Motorola's new phone passed 3C certification, supports 68W fast charging

Next article:Dalian Da Quanding Group launches smart TWS headset charging box solution based on Qualcomm and Richtek products

Recommended ReadingLatest update time:2024-11-15 05:39

- Popular Resources

- Popular amplifiers

- Apple and Samsung reportedly failed to develop ultra-thin high-density batteries, iPhone 17 Air and Galaxy S25 Slim phones became thicker

- Micron will appear at the 2024 CIIE, continue to deepen its presence in the Chinese market and lead sustainable development

- Qorvo: Innovative technologies lead the next generation of mobile industry

- BOE exclusively supplies Nubia and Red Magic flagship new products with a new generation of under-screen display technology, leading the industry into the era of true full-screen

- OPPO and Hong Kong Polytechnic University renew cooperation to upgrade innovation research center and expand new boundaries of AI imaging

- Gurman: Vision Pro will upgrade the chip, Apple is also considering launching glasses connected to the iPhone

- OnePlus 13 officially released: the first flagship of the new decade is "Super Pro in every aspect"

- Goodix Technology helps iQOO 13 create a new flagship experience for e-sports performance

- BOE's new generation of light-emitting devices empowers iQOO 13 to fully lead the flexible display industry to a new level of performance

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- [Important] Core Route FPGA Learning Motherboard Schematic Diagram PCB Engineering File Open Source Sharing

- Application of the concepts of virtual short and virtual disconnect in operational amplifiers in actual product circuits

- What is the application of PWM

- Detailed explanation of protection circuit design for intelligent motor system

- Guess the questions in the electronic competition and win prizes!

- MSP430f5529

- I am a PCB newbie and would like to ask about the relationship between PCB trace width and current carrying capacity.

- A single-phase three-phase static AC dual power supply conversion switch device

- MicroPython asyncio documentation

- 【MM32 eMiniBoard Review】3. Testing ADC Accuracy and Linearity + A Little Technique That May Have Been Lost

Battery Management Systems for Electric and Hybrid Vehicles

Battery Management Systems for Electric and Hybrid Vehicles

京公网安备 11010802033920号

京公网安备 11010802033920号