Recently, Intel has achieved mass production of the Intel 3 process node as scheduled in accordance with its "four-year five process nodes" plan. The first product using this node, the Intel® Xeon® 6 Energy Efficient Core processor code-named Sierra Forest, has been launched to the market. The new product is aimed at data centers and is born for the cloud, bringing a double improvement in performance and energy efficiency. The

Intel® Xeon® 6 Performance Core processor (code-named Granite Rapids), which is expected to be launched in the third quarter of 2024, will also be built on Intel 3.

How does Intel 3 process technology help new products achieve a leap forward?

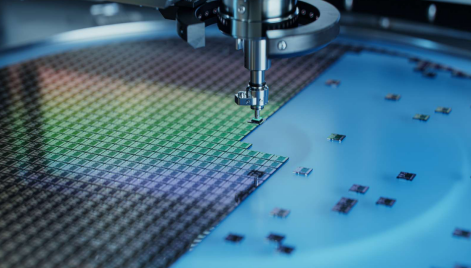

Compared with the previous process node Intel 4, Intel 3 achieved about 0.9 times the logic shrink and 17% performance per watt improvement. The current practice in the semiconductor industry is that the naming of process nodes is no longer based on the actual physical feature size of the transistor, but is based on a certain percentage of performance and energy efficiency improvement. Compared with the general industry standard, Intel 3's 17% is a higher level of improvement. In addition, compared with Intel 4, Intel is more proficient in the use of EUV (extreme ultraviolet lithography) technology, and has increased the use of EUV in more production processes of Intel 3. Intel 3 also introduced a higher density design library, improved transistor drive current, and optimized the interconnect technology stack by reducing through-hole resistance. It should also be emphasized that thanks to the practical experience of Intel 4, Intel 3 has also achieved faster production increases.

In the future, Intel will also launch multiple evolutionary versions of Intel 3 to meet the diverse needs of customers. In response to the huge demand for advanced packaging in the AI era, Intel 3-T will optimize 3D stacking by using through-silicon via technology; Intel 3-E will achieve functional expansion, such as RF and voltage adjustment; Intel 3-PT will achieve at least 5% performance improvement while adding through-silicon via technology.

Intel 3 is an important node, and its mass production marks the entry of the "four-year five-process node" plan into the "sprint stage" . Next, Intel will usher in the "Angstrom era" of semiconductors, and more new technologies will be put into use. Intel 20A will begin production in the second half of 2024 with Arrow Lake client processors, and Intel 18A will begin production in 2025 with Clearwater Forest server processors and Panther Lake client processors, and will be open to Intel foundry customers.

Previous article:China Academy of Information and Communications Technology announces AI code large model evaluation, Alibaba Cloud, Huawei, SenseTime and others are among the first to pass

Next article:Fastest chipset to help build next-generation wireless systems, with transmission speeds of 640Gbps, 10 to 100 times faster than current 5G systems

- Popular Resources

- Popular amplifiers

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Qualcomm launches its first RISC-V architecture programmable connectivity module QCC74xM, supporting Wi-Fi 6 and other protocols

- Microchip Launches Broadest Portfolio of IGBT 7 Power Devices Designed for Sustainable Development, E-Mobility and Data Center Applications

- Infineon Technologies Launches New High-Performance Microcontroller AURIX™ TC4Dx

- Rambus Announces Industry’s First HBM4 Controller IP to Accelerate Next-Generation AI Workloads

- NXP FRDM platform promotes wireless connectivity

- WPG Group launches Wi-Fi 7 home gateway solution based on Qualcomm products

- Exclusive interview with Silicon Labs: In-depth discussion on the future development trend of Bluetooth 6.0

- Works With Online Developer Conference is about to start, experience the essence of global activities online

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- Bidirectional thyristor circuit wiring problem

- CMS32F033SS24 wireless charging and security chip

- Selection and application of DCDC module power supply

- Basic Concepts of Wireless Communication

- Download: Qorvo "Basics of Power Management"

- [National Technology N32G457 Review] 4. Serial port 2 DMA interrupt reception and transmission

- When a person gets an electric shock, is the current more harmful or the voltage more harmful?

- TMS320C6748 Development Board——EDMA

- Variable assignment in Verilog parallel statements

- [National Technology N32G430] 7. CAN test

ISO121G

ISO121G

京公网安备 11010802033920号

京公网安备 11010802033920号