In the context of increasingly fierce global competition for civilian machines such as mobile phones and household appliances, personalized design has become an important factor. Therefore, designs and display methods created using various devices are being adopted by people, especially with the recent development of LEDs towards miniaturization and thinness, various display parts of electronic devices are equipped with LED dot matrix displays, and the keyboards and casings of mobile phones are decorated with gorgeous LEDs, and more and more electronic devices with improved design are increasing. In addition, in the field of white goods, the markets in China, India and other countries, which are maturing to a considerable extent, are also developing towards high performance. Many displays and decorations using LEDs can easily make people feel different visually, so the demand is expanding.

LED driver development trends

In this context, decorative LED driver ICs that supply current to LEDs to light them are required to be able to control a larger number of LEDs with more flexible lighting patterns.

However, the constant current LED drivers used in LCD backlights and other applications in the past used a structure that used one constant current circuit for one LED element. Increasing the number of LED lights would increase the chip area and cost, so they were often avoided. However, in recent years, LEDs have made progress in terms of high brightness, and a smaller current value can be used to light up the LED with sufficient brightness without increasing the constant current circuit itself. The power supply (positive electrode) side of the LED has built-in PMOS transistors that are driven in sequence to light up in time, so that a larger number of LEDs can be controlled separately (Figure 1). As shown in the figure, the conventional LED driver uses a 6-channel constant current circuit to light up 6 LEDs, while the dot matrix driver uses a 3-channel SW circuit and a 3-channel constant current circuit to control the lighting of 9 LED elements separately.

[Figure 1] Circuit structure of traditional LED driver and dot matrix LED driver

Control 119 LED elements individually

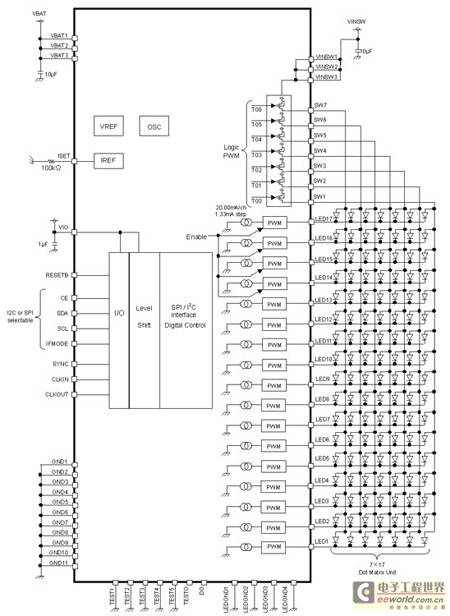

Generally speaking, the frequency that human vision can perceive is below 100Hz. Even if the LED flashes at a faster speed, it will be seen as the brightness averaged by the ON/OFF ratio (=Duty). This is called PWM (=Pulse Width Modulation) control method, which is widely used as a dimming method for LED drivers. By controlling the ON duty of the constant current circuit, the DC constant current value (=LED brightness) can be adjusted (for example, when the constant current value is set to 20mA and the ON duty is set to 50%, it is the same as a constant current of 10mA passing through continuously). The dot matrix LED driver uses the matrix connection and combination method shown in Figure 1 to control the number of LED elements equal to the SW circuit × constant current circuit part (Figure 2). The dot matrix driver connects the positive and negative poles of the LED elements in a matrix shape, and turns on the SW circuit on the positive side in a time-sharing manner. The constant current circuit on the negative side drives the constant current value set for each LED element at its own ON timing to light the LED. The BD26502GUL developed by ROHM has a built-in 7-channel SW circuit and 17-channel constant current circuit, and can control a total of 7x17=119 LED elements (Figure 3).

BD26502GUL lights up in a time-sharing manner with a cycle of about 4msec (=250Hz). Since the SW circuit has 7 channels, the lighting time of each LED element is 1/7 of the cycle. Therefore, the LED current averaged over time is equal to 1/7 of the value set by the constant current circuit. For the BD26502GUL type, even if it is calculated according to the maximum value set by the constant current circuit (=20mA), that is, 20mA/7≒2.9mA, the luminous efficiency of the LED is improved, and it can ensure a high enough brightness for display and decoration purposes.

[Figure 2] Example of operation based on a dot matrix LED driver (Figure 1)

[Figure 3] Example of LED control circuit configuration of BD26502GUL

[page]

Features of BD26502GUL

In addition, it is not just about lighting up multiple LEDs. It is also important to realize a "eye-catching" and "beautiful" lighting mode without increasing the CPU load for control. The BD26502GUL has built-in 13 modes of tilt function and 8-direction automatic scrolling function, which can achieve expressive LED lighting effects without adding load to the CPU (Figure 4, 5). In addition, it is equipped with a RAM that can store 7x17 matrix lighting data on both sides, and by repeatedly displaying and erasing these data, a dynamic effect like an animation can be achieved.

BD26502GUL has a control clock input and output port, and multiple ICs can be operated simultaneously (Figure 6). Tilt and scroll functions usually use a built-in oscillation circuit to generate a clock to control the time, but the internal oscillation circuit has frequency deviations among multiple ICs, so it is impossible to form a completely unified lighting pattern in terms of time. With this IC, this clock can be switched to an external input from a pin, so that the lighting timing and tilt and scroll time between multiple ICs can be synchronized using the same clock. As shown in Figure 6, all ICs can be controlled synchronously with the same clock signal by inputting a clock from the clock source to each IC in parallel or by connecting the clock input/output ports of this IC in series. With this function, even applications with more than 7×17=119 LED components can achieve completely synchronized lighting control without any sense of disharmony.

[Figure 4] 13-mode tilt function that can be set for each LED element (reducing CPU load)

[Figure 5] Example of the scrolling function of BD26502GUL

[Figure 6] An example of a configuration where multiple BD26502GULs operate simultaneously

[page]

In addition, ROHM's original technology has been used to reduce the saturation voltage of the constant current circuit to a very low 50mV (ROHM's evaluation). The so-called saturation voltage is the minimum operating voltage of the transistor used in the constant current circuit. If the voltage is lower than the saturation voltage, the drive current of the constant current circuit decreases, and the desired LED brightness cannot be obtained. In recent years, the market for smartphones is expanding, with large display screens and multiple functions. Users are dissatisfied with the so-called "battery is dead", and strict requirements have been put forward for reducing the power consumption of LED drivers, which account for a large proportion of the power consumption of the entire mobile phone. Conventional LED drivers require a boost circuit to ensure the Vf of the LED element. The efficiency of this boost circuit is an important factor that determines the durability of the battery and is therefore valued by people.

However, as the Vf of LEDs decreases, there are many cases where Vf can be achieved without a boost circuit and only with the battery power supply voltage, so the key is the saturation voltage mentioned above. Since a voltage as low as the Vf of the LED is applied to the constant current driver pin using the power supply voltage, the lower the saturation voltage, the wider the range in which the LED can be lit normally without a boost circuit (Figure 7).

[Figure 7] Constant current drive circuit and drive time of LED driver

ROHM has made full use of the LED driver technology cultivated over many years to develop not only dot matrix drivers, but also display and decoration LED dot matrix drivers corresponding to the personalization and sophistication of devices in various product fields (Table 1).

The company plans to continue expanding and enriching its product line, including products for RGB decoration (BD1606MUV, BD28xx) and OpenDrain type display drivers (BD7844EFV) that can be adapted to various applications, so that users can choose according to various applications.

[Table 1] LED dot matrix driver product list (☆Under Development ★Under Planning)

Previous article:Design and implementation of personalized digital TV user interface

Next article:ROHM's original LED high heat dissipation packaging technology and the latest development trends

Recommended ReadingLatest update time:2024-11-16 18:11

- Popular Resources

- Popular amplifiers

- Innovation is not limited to Meizhi, Welling will appear at the 2024 China Home Appliance Technology Conference

- Enjoy big-screen gaming anytime, anywhere: Making portable 4K UHD 240Hz gaming projector a reality

- AMD surpasses Intel: CPU shipments surge in Q3 this year

- Exynos is losing ground, Samsung plans to use Qualcomm chips in home appliances

- Intel and 50 partners unveiled a full range of 30 notebook and desktop AI PCs equipped with Intel Core Ultra (2nd Generation)

- Innovation leads the new trend of mobile refrigeration GMCC will present new products at 2024 CIAAR

- Lenovo and NVIDIA expand collaboration to jointly launch new liquid-cooled AI servers

- Ceiling fan solution based on XMC1302

- Gartner: Global AI PC shipments are expected to account for 43% of total PC shipments in 2025

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Installation and Testing of Analog Electronic Products (Edited by Chen Jingzhong and Tang Mingjun)

Installation and Testing of Analog Electronic Products (Edited by Chen Jingzhong and Tang Mingjun)

京公网安备 11010802033920号

京公网安备 11010802033920号