Today we summarize some common problems that are more likely to occur during the design process.

-

The two CC1 and CC2 pins of the TYPE-C USB charging case cannot be short-circuited together, and each must be connected to a pull-down resistor independently:

If CC1 and CC2 are short-circuited, the PD adapter will not charge the battery, because the PD device has a detection mechanism.

2. The distance between the Hall device and the magnet on the charging box should be controlled within 3MM. If it exceeds this distance, detailed reliability verification is required, because the magnet will demagnetize after high temperature. If the distance between the two is too far, the Hall sensor may fail.

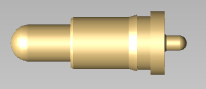

3. The bottom of the charging ejector pin needs to have a PCB through hole, so that the reliability of the design is more guaranteed.

4. The MIC structure of the headset must have a sealed design, especially for projects with ANC and ENC functions.

5. The charging pins and pads on the headset PCB are recommended to be designed according to the following ratios:

Because if the ejector pin is larger than the PCB pad, the reliability will not pass, and there may be a risk of falling off during the barrel test.

6. The speaker of the headset should not be placed too close to the battery. The two are very likely to interfere with each other, especially some highly sensitive speakers, which are more likely to be interfered with, such as hearing noise. So be especially careful.

7. The length of the battery cable should be controlled well, as it will have some impact on RF.

8. Antenna: The stability of RF signal is the most core hard indicator. The antenna types are mainly ceramic antenna and FPC antenna. The performance indicators of the antenna and the location of the antenna must be verified before the mold is opened. Once the structural mold is finalized, it is difficult to change. The RF performance of PCBA is relatively easy to verify. The most troublesome thing is the coordination between PCBA and structure, and the coordination between antenna and structure is the most time-consuming.

Previous article:Causes and solutions for howling during video calls

Next article:Introduction to High-Fidelity Audio Amplifier Chip

- Popular Resources

- Popular amplifiers

- Red Hat announces definitive agreement to acquire Neural Magic

- 5G network speed is faster than 4G, but the perception is poor! Wu Hequan: 6G standard formulation should focus on user needs

- SEMI report: Global silicon wafer shipments increased by 6% in the third quarter of 2024

- OpenAI calls for a "North American Artificial Intelligence Alliance" to compete with China

- OpenAI is rumored to be launching a new intelligent body that can automatically perform tasks for users

- Arm: Focusing on efficient computing platforms, we work together to build a sustainable future

- AMD to cut 4% of its workforce to gain a stronger position in artificial intelligence chips

- NEC receives new supercomputer orders: Intel CPU + AMD accelerator + Nvidia switch

- RW61X: Wi-Fi 6 tri-band device in a secure i.MX RT MCU

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- Why use WDM-PON in 5G fronthaul

- 【Iprober 520 Current Probe】Evaluation Report (II) Basic Performance Test

- MicroPython Hands-on (28) - Yeelight for the Internet of Things

- Basic operations and precautions for exporting Gerber files from PCB design (Part 1)

- Allegro cannot be installed due to VC2005. Is there any way to fix this?

- Has anyone used Sensortile Box? Please help~

- RFID semantic events in supply chain environment

- 【GD32307E-START】Light up an LED

- The MP3 purchased with E coins has arrived. It’s never too late to learn English!

- MSP430F5529 library functions

ISL70227SEHF/PROTO

ISL70227SEHF/PROTO

京公网安备 11010802033920号

京公网安备 11010802033920号