As automobiles become more intelligent, the closely related smart cockpits and autonomous driving functions place higher and higher demands on the chip's computing power. As the computing power of chips continues to increase, its power consumption is also increasing, and the scenarios it faces are becoming more complex and changeable. However, the market needs to reduce the overall power consumption as much as possible to extend the vehicle's cruising range. These changes and requirements bring to engineers A lot of new challenges:

High-speed computing chips use lower voltage power supplies, but inevitably bring greater current and smaller voltage margins

Scenarios are becoming more and more complex, resulting in more drastic load changes and higher current change rates.

Automotive safety requirements are higher, and any change in power supply caused by load changes may bring serious consequences.

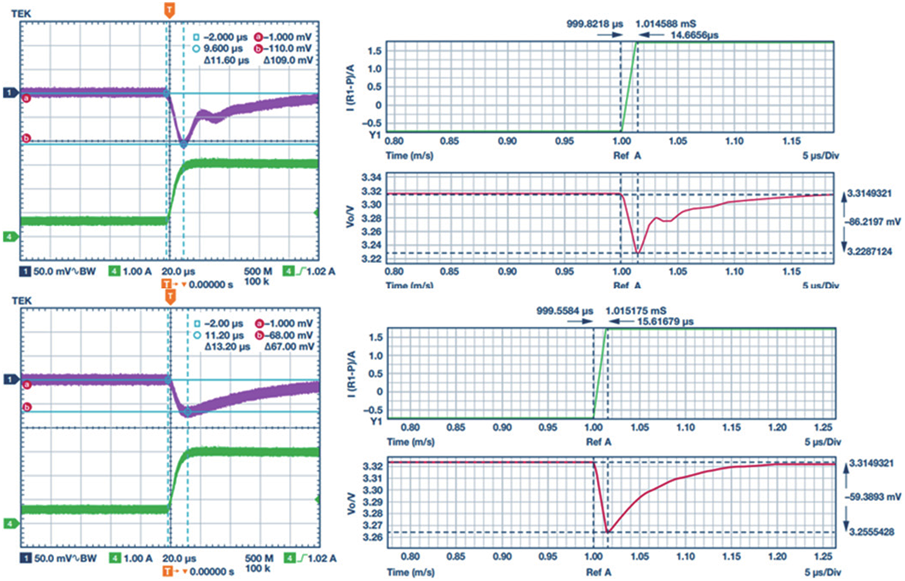

Chart 1. Under different loops, the same load change brings different voltage drops (refer to ADI)

As shown in the example above, under 3.3V power supply, when the load current jumps from 0.5A to 3A at a current change rate of 0.2A/us, using different power supply loops, the voltage drops are 67mV and 100mV respectively. Therefore, power loop response testing is an indispensable part of the current smart car domain controller hardware design and testing.

In the past, engineers usually needed to use specialized loop response testing equipment to complete power supply loop response testing; at the same time, oscilloscopes were also needed to complete testing of various other power supply parameters. This means that in order to complete the overall power supply test, companies not only have to spend more hardware investment costs, but also need engineers to spend more time learning and understanding related test equipment. So the question is, is there one device that can complete all power test items, thereby helping companies reduce hardware costs and employee learning costs?

In response to the above test pain points, Tektronix has added power loop analysis and testing capabilities that are essential for power supply testing to the existing 12-bit high-resolution oscilloscope MSO5/6B series oscilloscopes.

As shown in the figure, the AFG function generator function is integrated on the MSO5/6B series oscilloscope. The excitation signal is introduced into the loop through the injector. Through 12-bit high-precision acquisition, complete analysis of the entire loop is realized on the software. .

Tektronix MSO5/6B series oscilloscopes

In addition, the power supply test option of Tektronix MSO5/6 series oscilloscopes also includes the functions required for basic power supply testing, including power supply input and output stage analysis, power device analysis, power supply rejection ratio, output impedance test analysis and PDN Analysis of network impedance, etc. In this way, you only need a Tektronix high-precision oscilloscope to meet your domain controller power supply testing needs.

Tektronix MSO5/6B series oscilloscopes provide one-stop power test options and provide almost all power test items including loop response, which can help enterprises respond faster while reducing hardware cost investment and employee learning cost. The challenges of domain controller power supply testing under the current new electronic and electrical architecture help companies put products on the market faster and gain the upper hand.

Previous article:LIN/CAN bus automotive parts testing solution

Next article:Engineers say | Debugging/analysis solutions for in-vehicle multi-device

- Popular Resources

- Popular amplifiers

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- How much do you know about intelligent driving domain control: low-end and mid-end models are accelerating their introduction, with integrated driving and parking solutions accounting for the majority

- Foresight Launches Six Advanced Stereo Sensor Suite to Revolutionize Industrial and Automotive 3D Perception

- OPTIMA launches new ORANGETOP QH6 lithium battery to adapt to extreme temperature conditions

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions

- TDK launches second generation 6-axis IMU for automotive safety applications

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Melexis launches ultra-low power automotive contactless micro-power switch chip

- Molex leverages SAP solutions to drive smart supply chain collaboration

- Pickering Launches New Future-Proof PXIe Single-Slot Controller for High-Performance Test and Measurement Applications

- Apple faces class action lawsuit from 40 million UK iCloud users, faces $27.6 billion in claims

- Apple faces class action lawsuit from 40 million UK iCloud users, faces $27.6 billion in claims

- The US asked TSMC to restrict the export of high-end chips, and the Ministry of Commerce responded

- The US asked TSMC to restrict the export of high-end chips, and the Ministry of Commerce responded

- ASML predicts that its revenue in 2030 will exceed 457 billion yuan! Gross profit margin 56-60%

- Detailed explanation of intelligent car body perception system

- Exchange for E coins!!!

- The era of distributed edge computing is coming? What do you think about this?

- 5G commonly used terms, too comprehensive.

- [Teardown] What is the resolution of 20 million pixels? Do you really understand digital microscopes?

- LPS27HHTW MEMS Pressure Sensor

- CC2640R2F ADC

- Summary of the use of polarity and phase of MSP430 SPI

- How Designers Achieve Tri-Band Gigabit Speeds and High Throughput in Wi-Fi

- 【Development Kit for nRF52840】+ Evaluation of four Bluetooth serial port transparent transmission

- TMS320VC5502+ISP1581 USB2.0 high-speed data acquisition solution

AD8062AR

AD8062AR

京公网安备 11010802033920号

京公网安备 11010802033920号