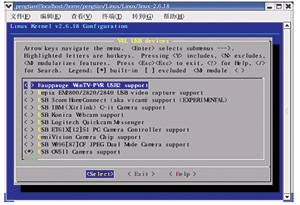

2 PC simulator development environment construction

Create your own development directory, unzip the files libminigui-1.3.3.tar.gz and minigui-res-1.3.3.tar.gz; compile and install the library file libminigui required for MiniGUI to run; install the resource file minigui-res-1.3.3; modify the /etc/ld.so.conf file, add a line /usr/local/lib, and then execute [root]# ldconfig to modify the minigui configuration file according to the hardware platform configuration and development environment settings, including modifying the path, screen resolution, etc.

After the PC simulator development environment is set up, you can develop applications on the PC and execute them in qvfb. After verifying the correctness of the program, you can cross-compile, download and run it.

3 Cross-compile Minigui1.3.3

Unzip the arm-Linux-2.95.3.bz2 file to install the cross-compilation tool? cross-2.95.3, modify it after installation. bashrc script, set the environment variable: PATH="$PATH:/sbin:/usr/local/arm/2.95.3/bin:/usr/local/bin:/usr/local".

Next, install the zlib library, png library, and libttf library in turn. Their functions are: compilation basis for other libraries, displaying PNG graphics, and displaying text. After completing the cross-compilation of the above additional libraries, you can compile libminigui. Copy the corresponding library in /usr/local/arm/2.95.3/arm-Linux/lib to the /usr/lib directory of the target board. When copying, execute the arm-Linux-strip command on the library file to remove the debugging information in the file. At the same time, copy the resource file to the /usr/local/lib directory of the target platform. In this way, the cross-compilation work is completed, and the application debugged on the PC can be downloaded to the target hardware platform for application.

Human-machine interface development for general industrial control platform

1 Human-computer interaction interface requirements analysis and overall design

The universal industrial control platform communication human-computer interaction interface is a human-computer interaction platform that integrates function demonstration, information collection, equipment status, communication interaction and other functions. It can efficiently and intuitively display the basic information of the universal industrial control platform, while effectively guiding the user's operation and improving the efficiency of use. It is the main way for users to interact with the universal industrial control platform.

The human-computer interaction interface display uses a 14-inch color display screen from PHILIPS. The software operating environment uses the embedded operating system Linux 2.6.21 and the GUI development environment MiniGUI 1.3.3. The entire software design process needs to complete the following functions:

(1) Display the specific information of the platform and the information of other industrial control equipment online in this network in real time;

(2) Using the platform as a controller, multi-threaded information collection and control of other common online devices in the network can be realized;

(3) Real-time control of the industrial control network using UDP and RS485 communication methods;

(4) Automatically disconnect industrial control equipment when it goes offline to prevent users from operating it incorrectly;

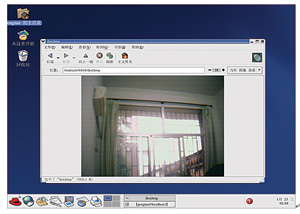

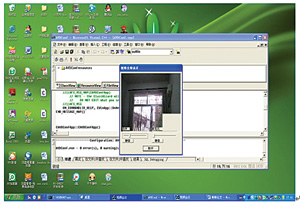

The general industrial control platform communication human-machine interaction interface is mainly based on the Modbus protocol to complete the function demonstration, information collection, equipment status, and communication interaction functions in the industrial control system for the two networking modes of UDP and RS485. The design requires simplicity, practicality, and easy operation. A complex interface will bring unnecessary overhead and affect performance. The overall design scheme and effect diagram of the human-machine interaction interface are set according to the demand analysis as shown in Figures 3 and 4.

Figure 3 Overall design of human-computer interaction interface

Figure 4 Overall effect diagram

2 Interface design process

The interface design process using MiniGUI is shown in Figure 5.

Figure 5 Interface design process

Communication implementation scheme based on industrial measurement and control Modbuss protocol

A good industrial control platform must have the function of efficient communication to keep up with the requirements of industrial development. The general industrial control platform designed in this paper can be used as a control center to collect and control data from other devices in the communication network, including typical digital-to-analog conversion equipment, analog-to-digital conversion equipment, digital quantity equipment, etc. in the industrial control field, so as to keep abreast of the situation of each work site at any time. Since the Modbus protocol is a standard communication protocol in the field of industrial measurement and control, the protocol is simple and widely used, so the design of the communication software of this platform adopts the Modbus protocol. The common networking methods in the field of industrial measurement and control mainly include UDP and RS485, which occupy a certain position in industrial networking with their own unique advantages. In order to achieve the design goal of the universality of the industrial control platform, this platform integrates the two networking methods into the communication human-computer interaction interface. Figure 6 is the topological structure diagram of the communication of this platform.

Figure 6 Communication topology

summary

In the development process of the general industrial control platform based on ARM and Linux, the hardware platform selects the appropriate ARM microprocessor AT91RM9200 and expands its peripheral components to adapt to the more abundant technical requirements of the current industrial control site, and combines fieldbus technology to expand a variety of communication interfaces to meet the communication needs of users; the software platform uses Linux, the most widely used operating system in the embedded field, and builds a cross-compilation environment at the same time, and makes full use of open source software. Based on the MiniGUI developed based on the graphical interface, an industrial control human-computer interaction interface based on UDP and RS485 two communication structures is designed for the bus protocol Modbus in the industrial control field, realizing a general industrial control platform based on ARM and Linux with strong network communication capabilities and rich interfaces as technical indicators.

The main features of this general industrial control platform are:

(1) Rich hardware interfaces to meet various needs in the field of industrial measurement and control;

(2) Use 3U slots to enhance versatility and expandability;

(3) Based on the Linux operating system and MiniGUI graphical interface development environment, the human-computer interaction interface is friendly and convenient;

(4) The industrial measurement and control Modbus communication protocol is adopted, and the communication topology is constructed based on serial RS485 and network UDP. It has a wide range of applications, reliable performance and high real-time performance.

Previous article:Establishment of ARM/uClinux development environment

Next article:Talking about the mutual growth of myself and ARM

- Popular Resources

- Popular amplifiers

- Naxin Micro and Xinxian jointly launched the NS800RT series of real-time control MCUs

- How to learn embedded systems based on ARM platform

- Summary of jffs2_scan_eraseblock issues

- Application of SPCOMM Control in Serial Communication of Delphi7.0

- Using TComm component to realize serial communication in Delphi environment

- Bar chart code for embedded development practices

- Embedded Development Learning (10)

- Embedded Development Learning (8)

- Embedded Development Learning (6)

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- Instrumentation amplifier of ordinary op amp

- Medical-grade computer with new and legacy ports

- [Erha Image Recognition Artificial Intelligence Vision Sensor] 1. Unboxing and Hardware Appreciation

- Internationalization of telecommunications companies

- Introduction to Gasoline Engine Sensors

- 01. Anlu SparkRoad domestic FPGA review [unboxing]

- Please tell me the difference between MPU6500/6050/6000

- Inductor Coil Introduction

- What is the IIC address of the LIS25BA bone vibration sensor?

- [GD32F350] Part 4: ModbusRTU protocol implementation

TC52N4948ECTRT

TC52N4948ECTRT

京公网安备 11010802033920号

京公网安备 11010802033920号