introduction

The panoramic vision system consists of an upward-facing camera and a reflective mirror. The camera obtains a 360-degree image through the reflective mirror. Because of its wide field of view, football competition robots usually use panoramic vision systems to obtain information about the entire field. The reflective mirror is an important factor affecting the image effect and observation range of panoramic vision. Simon Baker and Shree K. Nayar of Columbia University in the United States have conducted a detailed study and analysis of the geometric characteristics of panoramic vision systems and proposed the "single viewpoint" problem [1]. For a surface that conforms to a single viewpoint, all light rays directed to a focus are reflected and directed to another focus or parallel to the symmetry axis instead of being scattered.

Research shows that different mirrors are suitable for different observation requirements. Commonly used curved mirrors (such as paraboloids, cones, etc.) often cannot simultaneously meet the multiple observation requirements of robots performing special tasks. Therefore, some scholars have proposed to reverse the mirror surface based on the observation requirements or assumed imaging effects [2] to design a mirror profile that meets the requirements of special tasks. The mirror design process in this paper is to obtain the surface profile based on the reverse algorithm, and establish a corresponding model simulation to observe the imaging effect in advance, compare it with the expected imaging, optimize the parameters based on certain * estimation and analysis, and complete a large number of calculation processes and quantitative analysis by computer. This design method can efficiently design a mirror with good performance and low cost.

1 Mirror design principle and development of imaging simulation system

1.1 Mirror design principles and methods

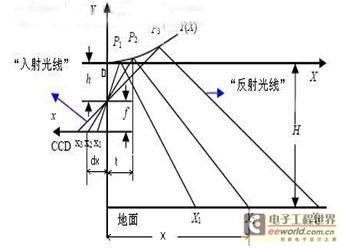

To predict the imaging effect after mirror reflection, it is necessary to know the mapping relationship between the mirror curve and the imaging point after mirror reflection (imaging unit on CCD) and the real space point.

Figure 1 Mirror imaging principle

Taking the pinhole imaging model as the imaging model of the camera, since the mirror surface is a rotationally symmetrical structure, only the two-dimensional mirror profile curve needs to be studied. As shown in the figure, according to the light reflection theorem and the pinhole imaging law, the following relationship can be obtained:

In the above formula, F(t) is the curve equation. For the derivation of the specific relationship, please refer to [4].

If the mirror curve equation is unknown, and the correspondence between the real point and the image point is given, the mirror contour line needs to be inferred. There are two methods to inversely obtain the mirror curve: analytical solution [2] and numerical solution [3]. This paper adopts the algorithm for numerical solution because it has low computational complexity and is easy to program. The main implementation process is shown in Figure 2:

Figure 2 Mirror profile design implementation flow chart

1.2 Imaging Simulation

In order to make the mirror curve design more intuitive and more convenient to adjust parameters, the simulation preview of the mirror imaging effect can make the design application more friendly, and at the same time help improve efficiency and design quality, avoid too much discrepancy between the design and the expected effect, resulting in waste of time and cost. The simulation system uses matlab as the development platform, because matlab has powerful mathematical calculation functions and image processing libraries, which can provide convenient function calls and shorten the time of simulation system development.

The imaging graphics are simulated according to the mapping relationship between the above-mentioned image and the actual space vector. First, it is necessary to obtain the environment for mirror imaging. The environment used for simulation in this article is the competition field of the soccer robot (including the white lines, goals, goal posts, etc. on the field) and the game ball. The object information on the field is a simple regular geometric body. After determining the global coordinate system, the spatial expression of each object, that is, their mathematical model, can be obtained. Assuming that the center of the field is the origin of the global coordinate system, according to the right-hand rule, the length direction is the x-axis (pointing to the yellow goal), the width direction is the y-axis, and the z-axis is perpendicular to the ground and upward, then the mathematical model of the main object is as follows (the calculation unit is mm):

ball:

(where r=110)

Yellow goal:

Blue goal:

Blue goal:

Assume the robot's position in the field is (dx, dy, θ) T, where dx and dy are the plane coordinate positions and θ is the robot's orientation angle. The mathematical model of the object (x, y, θ) T and the expression (x', y', z') T in the local coordinates with the robot's vision system as the origin have the following relationship:

Because the mirror is a rotationally symmetric mirror, in order to simplify the calculation of the simulated imaging, θ=0. So the transformation matrix is simplified to:

The imaging effect diagram of the designed virtual environment can be obtained based on the relationship between pixels and space vectors (points on the object model must pass through a certain space vector) calculated previously. Then, the parameters are modified according to the imaging effect diagram, and the desired effect is quickly achieved through imaging simulation, and the final mirror processing parameters can be obtained.

2 Experiments and Results

The mirror designed for the soccer robot must meet the following requirements:

1) When the robot is in the middle of the field, it needs to see the goal in order to distinguish its own goal from the opponent's goal and determine the direction of movement.

2) The distant ball should be seen with more accurate directional information.

3) The nearby ball must have relatively accurate direction and distance information, which means that the nearby observation resolution must meet certain requirements.

4) See as little of the robot itself as possible (useless information) so as to obtain more information about the environment around the robot.

According to the above requirements, the mirror can be divided into two parts, one for observing the range within 1m of the robot, and the other for observing information 1m away and the goal. The implementation process is as follows:

Consider the distribution of the observation area of the entire image in advance, allocate resolutions in different distance intervals, and then run the simulation program to obtain the mirror curve and imaging effect (see Figure 3), and save the coordinates of each point of the mirror curve into a data file to facilitate the subsequent CNC lathe processing and data extraction. The actual mirror imaging effect is shown in Figure 4.

Figure 3 Mirror cross-section and imaging effect diagram

Figure 4 The processed reflective mirror and the actual mirror image

3 Conclusion

Through the computer-aided design method of virtual simulation and the mirror inverse algorithm, the reflective mirror of the panoramic vision system can be conveniently and effectively designed to meet the pre-conceived task requirements and is well applied in soccer robots. With the help of computer-aided design and simulation methods, product design not only improves efficiency, but also improves the quality of design, and can focus on innovation rather than some tedious calculations and parameter refinement.

Previous article:Design of camera based on Gigabit Ethernet interface

Next article:Design of earthquake information acquisition module based on ADS1255

- Popular Resources

- Popular amplifiers

- High signal-to-noise ratio MEMS microphone drives artificial intelligence interaction

- Advantages of using a differential-to-single-ended RF amplifier in a transmit signal chain design

- ON Semiconductor CEO Appears at Munich Electronica Show and Launches Treo Platform

- ON Semiconductor Launches Industry-Leading Analog and Mixed-Signal Platform

- Analog Devices ADAQ7767-1 μModule DAQ Solution for Rapid Development of Precision Data Acquisition Systems Now Available at Mouser

- Domestic high-precision, high-speed ADC chips are on the rise

- Microcontrollers that combine Hi-Fi, intelligence and USB multi-channel features – ushering in a new era of digital audio

- Using capacitive PGA, Naxin Micro launches high-precision multi-channel 24/16-bit Δ-Σ ADC

- Fully Differential Amplifier Provides High Voltage, Low Noise Signals for Precision Data Acquisition Signal Chain

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- The talented photographer photographed 150 countries in 10 years, capturing the ultimate beauty of Chinese ink painting and astonishing the world!

- Can a multi-turn potentiometer be used for direction detection?

- SHT31 evaluation + mobile phone APP connection successful

- Analog Dialogue Reading Notes - High-Speed Op Amp Layout Tips

- Identification and identification of SMD diodes

- How to learn Altera Cyclone IV

- si114x infrared sensor

- How can we add isolation to an ADC without compromising its performance?

- [[HC32F460 development board review] (Part 2) Review of three low-power modes of the HC32F460 microcontroller

- TI's Sitara AM3352 processor with up to 1 GHz and rich peripheral resources

ISO164P

ISO164P

京公网安备 11010802033920号

京公网安备 11010802033920号