As large-area image sensors continue to develop, the printed electronics market has also expanded to include applications such as piezoelectric sensors, temperature sensors, capacitive adaptive force sensors, and biosensors that can play a role in the COVID-19 pandemic...

The $3.6 billion, increasingly diversified printed electronics/sensors market is expected to grow 25% over the next decade, driven by the expansion of hybrid image sensors that can be manufactured with only minor modifications to existing CMOS sensor production lines.

Market research firm IDTechEx Research said that the above advantages have greatly reduced the barriers to entry into the market, so the agency optimistically predicts that by 2030, the fully printed sensor market will reach US$4.5 billion.

Printed sensor technology has always been driven by the demand for blood sugar concentration measuring devices (test strips) for diabetics, with billions of such test strips used each year. However, the applications of printed sensors are becoming more and more diverse, with other applications such as wearable electrodes and image sensors.

"These diverse applications range from very simple sensor structures with only a few layers to more complex ones requiring multiple deposited layers and the use of sophisticated, innovative materials," said Matthew Dyson, technology analyst at IDTechEx Research, in a blog post.

As large-area image sensors continue to develop, the printed electronics market is also expanding to include applications such as piezoelectric sensors, temperature sensors, capacitive adaptive force sensors, and biosensors that can play a role in the COVID-19 pandemic.

IDTechX also predicts the rise of hybrid image sensors, which are based on organic semiconductor technology or quantum dot nanoscale crystals printed on silicon circuits. Dyson said: "Hybrid image sensors can be manufactured using modified CMOS production lines, significantly reducing capital requirements."

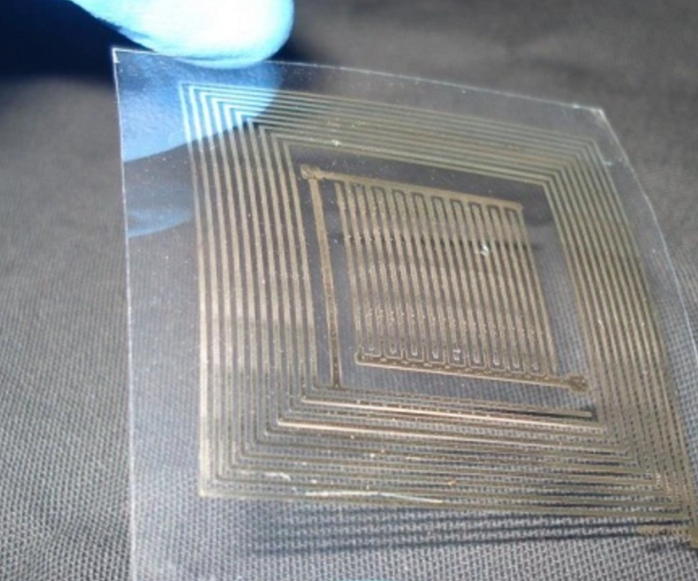

The application of printed electronics market is becoming increasingly diversified. (Image source: IDTechEx Research)

Image sensors based on printed organic photodiodes are another promising printed electronics technology; unlike traditional CMOS image detector components, this technology is softer and lighter than silicon image sensors that can be printed using cheap manufacturing technology.

While printed biosensors such as blood glucose test strips will continue to be the main driver of the printed electronics market, emerging wearable electrodes that can support a wide range of medical and fitness applications are expected to bring new growth momentum; IDTechX said: "The application of printed wearable electrodes in the medical and fitness fields is expected to grow with the development of continuous monitoring software and create a large demand."

The agency pointed out that the application market of traditional blood sugar test strips will gradually shrink, and skin patch solutions will become a new driver of the printed electronics market.

Previous article:ams high-level CT detector can improve the efficiency of COVID-19 diagnosis

Next article:2020 Medical Endoscopy Technology Development Seminar, OmniVision Promotes the Third Eye of Medicine

- Popular Resources

- Popular amplifiers

- High-speed 3D bioprinter is available, using sound waves to accurately build cell structures in seconds

- [“Source” Observation Series] Application of Keithley in Particle Beam Detection Based on Perovskite System

- STMicroelectronics’ Biosensing Innovation Enables Next-Generation Wearable Personal Healthcare and Fitness Devices

- China's first national standard for organ chips is officially released, led by the Medical Devices Institute of Southeast University

- The world's first non-electric touchpad is launched: it can sense contact force, area and position even without electricity

- Artificial intelligence designs thousands of new DNA switches to precisely control gene expression

- Mouser Electronics provides electronic design engineers with advanced medical technology resources and products

- Qualcomm Wireless Care provides mobile terminal devices to empower grassroots medical workers with technology

- Magnetoelectric nanodiscs stimulate deep brain noninvasively

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- The world's first integrated 5G baseband processor Kirin 990 5G was released today

- [CH579M-R1] + Help: Simulating I2C to read data failed (solved)

- CC2530 RF part use - to achieve point-to-point transmission and reception

- Cut the charging cable TI wireless charging solution to unlock a variety of applications

- Bicycle modification series: headlights

- [Qinheng RISC-V core CH582] I2C lights up the OLED screen

- Area Occupancy Detection Reference Design for mmWave Sensors

- Multi-axis drone airbag

- I bought an old power supply, and this method of cleaning dust is the most effective

- MSP430 MCU Development Record (27)

JM38510/10102BDA

JM38510/10102BDA

京公网安备 11010802033920号

京公网安备 11010802033920号