1 Introduction

In modern armored communication and command equipment, powerful, precise and reliable equipment is composed of more and more electronic extensions and components connected by dense cables, harnesses and networks.

The correctness and reliability of cable and network connections play an important role in ensuring the reliable operation of the entire electronic system. Automatic testing and inspection of the conductivity, insulation and other indicators of complex cables, harnesses and networks are an indispensable part of the cable assembly and production process. Traditional low-voltage and low-current manual and semi-automatic testing are far from meeting the needs of modern high-reliability electronic equipment production.

At present, the cable detection of armored communication and command equipment adopts the traditional and backward manual detection method, using a multimeter, buzzer and a simple homemade test bench to detect the continuity. The manual detection method has many insurmountable defects and can no longer meet the requirements of large-scale, high-precision and high-reliability cable detection:

(1) One or two people cooperate in point-by-point detection, which is inefficient, slow, labor-intensive, delicate, tedious, boring and easy to fatigue. It is necessary to compare drawings, wiring tables and core wire numbers, which is very easy to cause missed detection and wrong detection.

(2) It can only detect the path, but cannot detect short circuits (i.e. wrong connection or multiple connection) in dozens of core cables.

(3) It generally only detects continuity, but not on-resistance, and cannot detect poor contact or unreliable contacts.

For the above reasons, it is urgent to develop a special detection device that can automatically test the cables of armored communication and command equipment.

2 System Design Principles

The system structure is shown in Figure 1.

The functions of each functional block are as follows:

2.1 PC

The main function of the PC is the built-in "cable management system", including: cable model, specifications, socket model specifications, cable spectrum, etc., as well as the storage and analysis of test results.

2.2 Host

The host stores the spectrum of the tested cable downloaded from the "cable management system" through the serial port. Up to 150 cable spectra can be stored. It does not need to be connected to the PC during testing. The display mode uses a 320×240 wide temperature LCD display. During the test, the host sends a test command to the slave through the wireless according to the spectrum of the selected tested cable. The host and the slave cooperate in real time to complete the measurement.

2.3 Slave The slave

consists of a programmable switch matrix and a load, and receives the test command from the host. 2.4 Cable-specific conversion connector The cable-specific conversion connector is used to connect the tested cable to the host and the slave respectively through the conversion connector to complete the measurement. Each type of tested cable requires a pair of conversion connectors. 3 Hardware system on the system platform The host consists of a main control unit, a transceiver unit, a switch matrix, a display and keyboard, a power supply, etc. Its structure is shown in Figure 2.

3.1 Introduction to LH79520

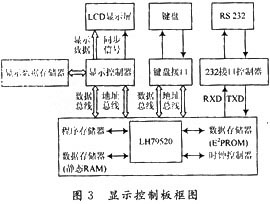

LH79520 is an integrated system-on-chip (SoC) based on the 32-bit ARM7 core. It includes a 32-bit ARM7TDMI RISC processor core designed by ARM, Cache RAM, a write buffer and a storage management unit. It has the characteristics of low power consumption and high performance. [page] 3.2 Block diagram of display control board The block diagram of the display control board is shown in Figure 3.

The display and keyboard control system consists of CPU, display, keyboard, RS 232 interface and data exchange. The CPU is LH79520. In order to meet the need of storing some data, 32 kB E2PROM is used as data storage to store some test results. The display part uses OKI's MSM6255 as the display controller, and an external 32 kB RAM is used as the display data storage. The horizontal synchronization signal, field synchronization signal and display data generated by MSM6255 are sent to the EL display screen. The keyboard part uses 8279 as the keyboard controller. In order to realize the control of the instrument by an external computer, the system uses the factory MAX202 as the interface level conversion control, and uses the RS 232 interface to connect to the external buffer. 3.3 Slave block diagram The slave block diagram is shown in Figure 4. The transceiver module is composed of the nrf401 single-chip transceiver module as the core and the peripheral circuit. The operating frequency is 133.92 MHz, the modulation mode is FSK, and the maximum transmission rate is 20 kb/s. The built-in antenna has a maximum straight-line transmission distance of 100 m.

4 Software system on the system platform

4.1 Design of continuity test algorithm

4.1.1 Establishing port relationship matrix

The design of port relationship matrix is shown in Table 1.

Note: (1) This matrix is used to describe the correspondence between cores and ports;

(2) N = 61:

(3) This matrix corresponds to the cable type spectrum;

(4) The upper triangular matrix is valid, including the diagonal;

(5) 0: indicates no connection; 1: indicates connection; X: indicates invalid.

4.1.2 Establishing the cable relationship matrix

Note: (1) This matrix is used for short circuit judgment (the result is written in Table 2) and partial path judgment (the result is written in Table 3);

(2) M is the maximum number of cable cores (2≤M≤61);

(3) The upper triangular matrix is valid, excluding the diagonal;

(4) 0: indicates invalid;

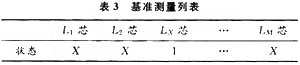

(5) X is initially 0; X=3 short; X=4 measurement failure (wireless communication error). [page] 4.1.3 Short circuit measurement Starting from the first row of the cable relationship matrix, scan the upper triangular matrix row by row. During the measurement process, if the result is a short circuit, set X=3; if the result is a measurement failure, set X=4 and continue. During the scanning measurement process, if the result is connected, the core numbers of the two connected cores LX and HY are changed to the corresponding column numbers of the reference measurement list. Reference measurement list (Table 3) column number: [LX]=LX; [LY]=HY Set the status of the reference measurement list column numbers [LX] and [LY] to X=1, and continue to scan the upper triangular array row by row with X=1. Definition of reference core: One of the two cores measured as connected is the reference core. This list is used to store the connection and disconnection results. X is initially 0; X=1 is connected; X=2 is disconnected; X=4 measurement failed (wireless communication error). Scan Table 3 to find the reference core. If all X are 0, the cables are all disconnected; if X is 1, the corresponding LX column number is used as the reference core. Use the reference core to judge the core with X as 0 in Table 3. If it is connected, set X=1; if it is disconnected, set X=2; if the measurement fails, set X=4. 4.1.4 Processing flow of cable continuity measurement

5 Conclusion

The continuity tester can automatically measure the special cables with 2 to 60 cores. Its main features are:

(1) Automatic and fast cable continuity test. The 750 points/s test speed enables the complex cables with dozens of cores to complete the continuity test in seconds.

(2) Automatic grouping and combination short-circuit test to detect all possible short-circuit errors (i.e. wrong connection, multiple connection).

(3) The program controls the automatic test process and can test the cables multiple times at any time, which is convenient for quality management and greatly improves work efficiency.

(4) Detects slight changes in contact resistance and finds out quality risks such as poor contact, broken wires, and missing parallel wires.

(5) Easy to use. Only one person is required to operate, the human-machine interface is friendly, and it is a handheld test device with ultra-low power consumption.

(6) It can store 512 types of cable spectra. The type input can be downloaded from the PC through the communication interface. The measurement results can be stored and transmitted to the management system.

Keywords:LH79520

Reference address:Design and implementation of automatic cable tester based on ARM7 core

In modern armored communication and command equipment, powerful, precise and reliable equipment is composed of more and more electronic extensions and components connected by dense cables, harnesses and networks.

The correctness and reliability of cable and network connections play an important role in ensuring the reliable operation of the entire electronic system. Automatic testing and inspection of the conductivity, insulation and other indicators of complex cables, harnesses and networks are an indispensable part of the cable assembly and production process. Traditional low-voltage and low-current manual and semi-automatic testing are far from meeting the needs of modern high-reliability electronic equipment production.

At present, the cable detection of armored communication and command equipment adopts the traditional and backward manual detection method, using a multimeter, buzzer and a simple homemade test bench to detect the continuity. The manual detection method has many insurmountable defects and can no longer meet the requirements of large-scale, high-precision and high-reliability cable detection:

(1) One or two people cooperate in point-by-point detection, which is inefficient, slow, labor-intensive, delicate, tedious, boring and easy to fatigue. It is necessary to compare drawings, wiring tables and core wire numbers, which is very easy to cause missed detection and wrong detection.

(2) It can only detect the path, but cannot detect short circuits (i.e. wrong connection or multiple connection) in dozens of core cables.

(3) It generally only detects continuity, but not on-resistance, and cannot detect poor contact or unreliable contacts.

For the above reasons, it is urgent to develop a special detection device that can automatically test the cables of armored communication and command equipment.

2 System Design Principles

The system structure is shown in Figure 1.

The functions of each functional block are as follows:

2.1 PC

The main function of the PC is the built-in "cable management system", including: cable model, specifications, socket model specifications, cable spectrum, etc., as well as the storage and analysis of test results.

2.2 Host

The host stores the spectrum of the tested cable downloaded from the "cable management system" through the serial port. Up to 150 cable spectra can be stored. It does not need to be connected to the PC during testing. The display mode uses a 320×240 wide temperature LCD display. During the test, the host sends a test command to the slave through the wireless according to the spectrum of the selected tested cable. The host and the slave cooperate in real time to complete the measurement.

2.3 Slave The slave

consists of a programmable switch matrix and a load, and receives the test command from the host. 2.4 Cable-specific conversion connector The cable-specific conversion connector is used to connect the tested cable to the host and the slave respectively through the conversion connector to complete the measurement. Each type of tested cable requires a pair of conversion connectors. 3 Hardware system on the system platform The host consists of a main control unit, a transceiver unit, a switch matrix, a display and keyboard, a power supply, etc. Its structure is shown in Figure 2.

3.1 Introduction to LH79520

LH79520 is an integrated system-on-chip (SoC) based on the 32-bit ARM7 core. It includes a 32-bit ARM7TDMI RISC processor core designed by ARM, Cache RAM, a write buffer and a storage management unit. It has the characteristics of low power consumption and high performance. [page] 3.2 Block diagram of display control board The block diagram of the display control board is shown in Figure 3.

The display and keyboard control system consists of CPU, display, keyboard, RS 232 interface and data exchange. The CPU is LH79520. In order to meet the need of storing some data, 32 kB E2PROM is used as data storage to store some test results. The display part uses OKI's MSM6255 as the display controller, and an external 32 kB RAM is used as the display data storage. The horizontal synchronization signal, field synchronization signal and display data generated by MSM6255 are sent to the EL display screen. The keyboard part uses 8279 as the keyboard controller. In order to realize the control of the instrument by an external computer, the system uses the factory MAX202 as the interface level conversion control, and uses the RS 232 interface to connect to the external buffer. 3.3 Slave block diagram The slave block diagram is shown in Figure 4. The transceiver module is composed of the nrf401 single-chip transceiver module as the core and the peripheral circuit. The operating frequency is 133.92 MHz, the modulation mode is FSK, and the maximum transmission rate is 20 kb/s. The built-in antenna has a maximum straight-line transmission distance of 100 m.

4 Software system on the system platform

4.1 Design of continuity test algorithm

4.1.1 Establishing port relationship matrix

The design of port relationship matrix is shown in Table 1.

Note: (1) This matrix is used to describe the correspondence between cores and ports;

(2) N = 61:

(3) This matrix corresponds to the cable type spectrum;

(4) The upper triangular matrix is valid, including the diagonal;

(5) 0: indicates no connection; 1: indicates connection; X: indicates invalid.

4.1.2 Establishing the cable relationship matrix

Note: (1) This matrix is used for short circuit judgment (the result is written in Table 2) and partial path judgment (the result is written in Table 3);

(2) M is the maximum number of cable cores (2≤M≤61);

(3) The upper triangular matrix is valid, excluding the diagonal;

(4) 0: indicates invalid;

(5) X is initially 0; X=3 short; X=4 measurement failure (wireless communication error). [page] 4.1.3 Short circuit measurement Starting from the first row of the cable relationship matrix, scan the upper triangular matrix row by row. During the measurement process, if the result is a short circuit, set X=3; if the result is a measurement failure, set X=4 and continue. During the scanning measurement process, if the result is connected, the core numbers of the two connected cores LX and HY are changed to the corresponding column numbers of the reference measurement list. Reference measurement list (Table 3) column number: [LX]=LX; [LY]=HY Set the status of the reference measurement list column numbers [LX] and [LY] to X=1, and continue to scan the upper triangular array row by row with X=1. Definition of reference core: One of the two cores measured as connected is the reference core. This list is used to store the connection and disconnection results. X is initially 0; X=1 is connected; X=2 is disconnected; X=4 measurement failed (wireless communication error). Scan Table 3 to find the reference core. If all X are 0, the cables are all disconnected; if X is 1, the corresponding LX column number is used as the reference core. Use the reference core to judge the core with X as 0 in Table 3. If it is connected, set X=1; if it is disconnected, set X=2; if the measurement fails, set X=4. 4.1.4 Processing flow of cable continuity measurement

5 Conclusion

The continuity tester can automatically measure the special cables with 2 to 60 cores. Its main features are:

(1) Automatic and fast cable continuity test. The 750 points/s test speed enables the complex cables with dozens of cores to complete the continuity test in seconds.

(2) Automatic grouping and combination short-circuit test to detect all possible short-circuit errors (i.e. wrong connection, multiple connection).

(3) The program controls the automatic test process and can test the cables multiple times at any time, which is convenient for quality management and greatly improves work efficiency.

(4) Detects slight changes in contact resistance and finds out quality risks such as poor contact, broken wires, and missing parallel wires.

(5) Easy to use. Only one person is required to operate, the human-machine interface is friendly, and it is a handheld test device with ultra-low power consumption.

(6) It can store 512 types of cable spectra. The type input can be downloaded from the PC through the communication interface. The measurement results can be stored and transmitted to the management system.

Previous article:Design of two power supply modes in handheld terminal tester based on ARM

Next article:Research on the Design of GPRS/CQT Test System Based on S3C2410

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Microcontroller Articles

- Learn ARM development(16)

- Learn ARM development(17)

- Learn ARM development(18)

- Embedded system debugging simulation tool

- A small question that has been bothering me recently has finally been solved~~

- Learn ARM development (1)

- Learn ARM development (2)

- Learn ARM development (4)

- Learn ARM development (6)

He Limin Column

Microcontroller and Embedded Systems Bible

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Guess you like

- An important representative enterprise in 70 chip sub-sectors in China!

- 【Badminton training monitor project】--main function realization

- [Repost] Impedance matching and 0 ohm resistor in PCB design

- PYB Nano UF2 bootloader beta version

- Is there any place in Beijing that can do small batch ASIC bare die bonding?

- How ADI builds a bridge from the physical world to the digital world through product changes

- Unboxing Review

- Supplementary information on the two disassembled isolators and detailed disassembly pictures

- MCU reset problem

- Please advise on PMOS high-side driver under wide voltage range!

LT1784CS5#PBF

LT1784CS5#PBF

京公网安备 11010802033920号

京公网安备 11010802033920号