Fault detection mechanisms are essential for industrial systems such as motor drives and photovoltaic inverters, as well as automotive systems including electric vehicle (EV) chargers, traction inverters, on-board chargers, and DC/DC converters.

Fault detection uses current, voltage, and temperature measurements to diagnose any AC power line fluctuations, mechanical or electrical overloads within the system . Upon detecting a fault event, the host microcontroller (MCU) performs protective actions such as shutting down or modifying the switching characteristics of a power transistor or tripping a circuit breaker.

To improve efficiency and reduce system size, designers are migrating from insulated gate bipolar transistors (IGBTs) to wide-bandgap silicon carbide (SiC) and gallium nitride (GaN) switching transistors, which enable faster switching speeds (>100kHz) and shorter withstand times (<5µs).

To protect the power switching transistors from fault conditions, the first step is to use a shunt-based or Hall-effect-based solution to detect overcurrent conditions. While Hall-effect-based solutions support a single-module approach, their measurement accuracy is low, especially at elevated temperatures. Other factors to consider when choosing between shunt-based or Hall-effect-based solutions include isolation specifications and primary conductor resistance. While the primary conductor resistance in both solutions may produce the same amount of heat dissipation, improvements in shunt technology now have much lower resistance, minimizing heat dissipation and providing very high accuracy over temperature and lifetime.

Let’s look at several shunt-based fault detection methods:

Using an isolated amplifier

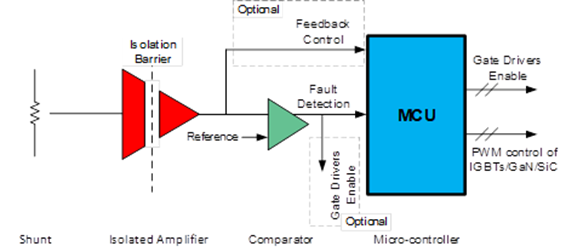

Figure 1 shows a shunt-based overcurrent detection solution with an isolated amplifier and a non-isolated comparator. You can use the same isolated amplifier for feedback control if necessary. The MCU receives the output of the comparator and sends a signal to control the enable pin of the gate driver or change the pulse width modulation period going into the gate driver input.

Figure 1: Fault detection using an isolated amplifier and a nonisolated comparator

The shunt-based approach provides high measurement accuracy for fault detection and feedback control using isolated amplifiers that provide basic or reinforced isolation.

However, the propagation delay of the isolated amplifier is 2µs - 3µs. Depending on the delay requirements for overcurrent detection , the isolated amplifier-based approach may not be fast enough.

Using an isolated modulator

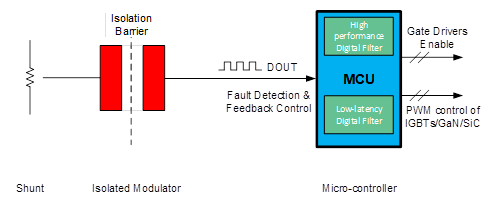

As shown in Figure 2, overcurrent detection and feedback control can be performed simultaneously using an isolated modulator. The isolated data output (DOUT) of the isolated modulator provides a digital bit stream consisting of 1s and 0s at a significantly higher frequency. The time average of this bit stream output is proportional to the analog input voltage, and the digital filter within the MCU reconstructs the measurement signal. The MCU can use the same bit stream output to run multiple digital filters in parallel, with one digital filter configured for high-precision feedback control and another digital filter configured for low-latency overcurrent detection.

Figure 2: Fault detection using an isolated modulator

Compared to isolated amplifiers, the shunt-based approach with an isolated modulator provides higher measurement accuracy for fault detection and feedback control. The propagation delay for overcurrent detection can be as low as 1µs in the worst case.

Using Standard Comparators and Digital Isolators

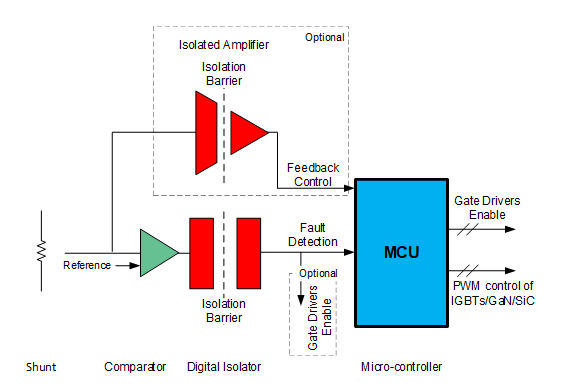

Figure 3 shows a standard non-isolated comparator followed by a digital isolator for overcurrent detection, and an isolated amplifier or modulator for feedback control. The propagation delay for overcurrent detection can be less than 1µs in the worst case, depending on the comparator and digital isolator selected. However, a discrete implementation takes up more printed circuit board (PCB) space and can become expensive for designs that require higher accuracy.

Figure 3: Fault detection using standard comparators and digital isolators

Using an Isolated Comparator

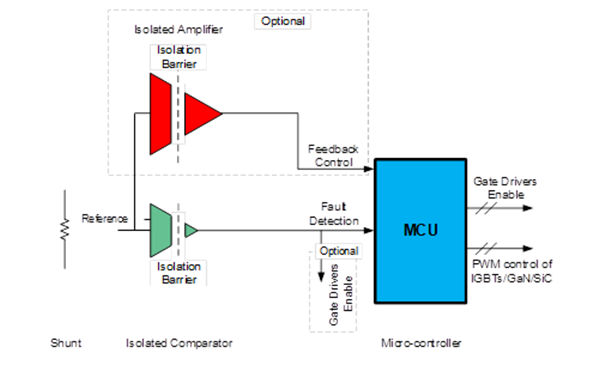

The isolated comparator shown in Figure 4 provides a small and ultrafast method for overcurrent detection by integrating the functionality of a standard comparator and a digital isolator. You can use either an isolated amplifier or an isolated modulator for feedback control.

Figure 4: Fault detection using isolated comparators

Isolated comparators such as the AMC23C12 provide a cost-effective, small form factor solution for fault detection. These devices feature very low latency (<400ns) for faster overcurrent detection . The AMC23C12 integrates a wide input range (3V - 27V) low dropout regulator to power the high side, a single window comparator, and a galvanic isolation layer, reducing PCB area by up to 50% and bill of materials compared to discrete implementations. With adjustable trip thresholds and less than 3% accuracy (worst case), the AMC23C12 family meets the growing demand for overcurrent, overvoltage, overtemperature, undervoltage, and undercurrent detection.

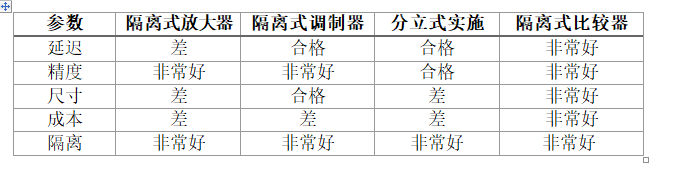

Table 1 compares various shunt-based fault detection methods.

Table 1: Comparison of shunt-based overcurrent detection methods

As the need for improved system resilience and adoption of faster switching transistors such as SiC and GaN surges, the need for accurate and fast fault detection becomes more important. The AMC23C12 series of isolated comparators can quickly detect a variety of fault events, helping designers develop high-voltage systems with higher fault tolerance.

Additional Resources

• Check out TI's isolated amplifiers and modulators.

• Read the Analog Design Journal article, “Using Isolated Comparators for Overcurrent and Overvoltage Fault Detection in Motor Drives.”

Previous article:WPG World Peace Group launches low-voltage brushless motor application solution based on MindMotion products

Next article:Nidec Air Purifier wins 2021 Energy Saving Award

- Popular Resources

- Popular amplifiers

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

- Focusing on promoting innovation and transformation, UHV field creates more possibilities in the era of clean energy

- Infineon Technologies Launches SECORA™ Pay Green, World’s First Contactless Payment Card Technology, Reducing Plastic Waste by Up to 100%

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- Can RS485 communicate stably using parallel wires (non-twisted pair)? 5m wire length, 9600bps

- TI Wired and Wireless Communications in Electric Vehicle Battery Management

- Do you know the audio and video expansion port and asynchronous serial port expansion of DSPs?

- [CH563L Review] Part 1 Based on the official uCos introductory Hello World

- Why is there a "red dot" on my forum icon?

- Is the signal mentioned in Nyquist sampling theorem limited to sine (cosine) signal form?

- Thank you for being there, thank you for being polite!

- How to locate the code and data of C program

- Color screen printing limit for color segment screen

- RF Personal Experience Sharing Series

TC52N2547ECTRT

TC52N2547ECTRT

京公网安备 11010802033920号

京公网安备 11010802033920号