Since LED is a semiconductor device with sensitive characteristics and negative temperature characteristics, it needs to be stabilized and protected during the application process, which gave rise to the concept of drive. LED devices have almost harsh requirements for driving power supplies. Unlike ordinary incandescent bulbs, LEDs can be directly connected to 220V AC mains. LEDs are driven by a low voltage of 2 to 3 volts, so complex conversion circuits must be designed. LED lamps for different purposes must be equipped with different power adapters. In the international market, foreign customers have very high requirements for the efficiency conversion, effective power, constant current accuracy, power supply life, and electromagnetic compatibility of LED driving power supplies. Designing a good power supply must comprehensively consider these factors, because the role of the power supply in the entire lamp is as important as the human heart.

LED is a typical current-driven device. Accurately controlling the LED driving current can determine many parameters including light efficiency, power efficiency, heat dissipation and product brightness. Driving LEDs is mainly about controlling their current. Whether it is directly increasing or decreasing the driving current, or reducing the switching time ratio by using the duty cycle (PWM), they are all ways to control the current, but the purposes they achieve are different. This article will explain the differences between different drivers in different applications.

1 Introduction to the principle of distributed constant current drive

In the past incandescent lamp and energy-saving lamp markets, the mainstream lamp models with limited specifications formed by large companies are difficult for LEDs to continue to comply with. LEDs have their application flexibility and will bring more power supply specifications in future designs.

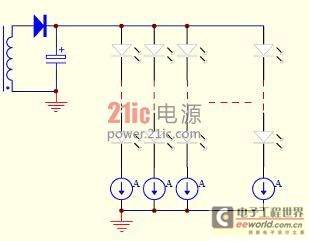

The principle of distributed constant current is to set up independent constant current sources at each parallel branch point to manage, maintain and control the stability of branches and branches, branches and the overall line. The distributed constant current circuit can be regarded as a complete line structure in use, and the actual application is distributed at each node of the line. It is a circuit structure that can be controlled by constant current and can communicate with each other.

At present, there is a big gap between the claimed lifespan of LED products and their actual lifespan. The stability of the driving circuit will directly affect the overall stability of the product.

The reason why distributed constant current technology has high reliability is that the AC power supply part continues to use the traditional switching power supply and adopts a constant voltage power supply mode. The accumulation of switching power supply technology will create quality conditions for LED power supply design. Under the same power supply specification, there is no need to develop new power supply models, and the power can be backward compatible, which greatly reduces the power supply specifications and improves the uniformity of the power supply.

2. Precision control ideas combining soft and hard

In daily drive power supply design, it is very difficult to handle the accumulated errors of peripheral devices, resulting in the drive power supply parameters being far from the original design intention. Constant current drive requires current detection. The usual practice is to connect a milli-resistance in series in the branch to obtain feedback information. To achieve high efficiency, the resistance value will be smaller. Too small milli-resistance brings inconvenience to production and testing. General instruments cannot verify the correct value, and the production process will also affect the accuracy. The resistance method is a fixed method to set the current, and it is not convenient to adjust.

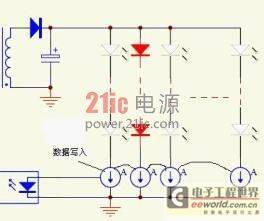

The combination of software and hardware will usher in a leap in LED application technology. The softwareization of LED constant current precision value can greatly improve the flexibility of LED application. The circuit current setting can be completed by microcomputer operation software with intuitive digital writing.

Our goal is to reduce the number of peripheral components in the driving circuit. The peripheral components will not cause the accumulation of design device parameter errors, thereby greatly improving the accuracy of constant current.

Our goal is to reduce the number of peripheral components in the driving circuit. The peripheral components will not cause the accumulation of design device parameter errors, thereby greatly improving the accuracy of constant current.my country's IC manufacturing process currently cannot meet the LED drive accuracy requirements, but we can use new technologies and methods to achieve the world's top constant current accuracy level. Precision drive control is one of the methods.

When performing precise control of the driver, the first thing to look at is what the design purpose is? Is it designed according to the highest light efficiency or the consistency of the lamp? If it is limited to the precision of the driving current, it is actually very easy to do. For example, the driving current is stable and accurate, or there is protection with temperature changes. Customers require that all parameters can meet the requirements, such as product consistency and efficiency.

We need to work hard on design drive to meet these requirements of customers. It all comes down to how to control the accuracy and finally adjust the current according to our design intention to improve the stability of the product.

The value can be realized. You can choose to build in non-volatile E2PROM. I believe that any register can complete its task, and the type of memory can be determined according to the application needs and the conditions allowed by the process.

The division and design of current levels may vary depending on the market. Due to manufacturing process reasons, the output current always has errors, which will be improved after softwareization.

Changyuntong's driver IC can provide different current output values according to different customer needs when it leaves the factory, eliminating the batch calibration process. Customers with small quantities can also rewrite the current value by themselves through the included microcomputer software.

3 New design method to improve drive efficiency

It is feasible to drive LEDs with AC power in a single series branch, but single series connection is only a small part of LED driver applications, and most applications involve parallel connection. In the case of parallel LED drive, the branch LEDs in the overall constant current design do not necessarily work in a constant current state, and the LED currents of the entire product affect each other.

Among high current designers, such as LED street light designers, designers will not directly connect multiple LEDs in parallel, because this will cause danger immediately. The usual practice is to first constant voltage and then DC constant current, and complete it through these two levels of design. We know that DC drive efficiency is under reasonable voltage and load conditions, so how to ensure that the number of load LEDs or the change of LEDs with temperature are within a reasonable range? How to flexibly allow customers to change the number of LED drivers? Solving the above problems requires the design of an AC to DC constant current feedback mechanism, but so far there is no technical condition for this.

Changyuntong adopts another approach: the company's distributed constant current driver can provide optocoupler driving capabilities, and one branch can be used as a representative of all branches. Distributed constant current branches can communicate with each other to achieve an adaptive linkage mechanism, while being compatible with control and data read and write interface functions. In addition, the peripheral design is zero-device, and the power supply output voltage matches the load impedance, thereby realizing the integration of constant current source and light source.

Previous article:Design and implementation of LED driver based on I2C interface

Next article:Experts teach you how to choose LED lighting driver chips

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

- Brief Analysis of Automotive Ethernet Test Content and Test Methods

- How haptic technology can enhance driving safety

- Please help provide the entire PCB board production process and the SMD component mounting process animation. Thank you

- Summary of DSP's real clock system--Explained with TI's DSP TMS320F2812 as an example

- E840-DTU device unresponsive problem

- Is it better to first increase the voltage to 5V and then decrease it to 3.3V when using a 3.7V lithium battery? Or is it better to first decrease it to 3.3V and then increase it to 5V?

- Download the Pomona Connectors catalogue and win a Xiaomi Mosquito Repellent!

- Are smaller components better?

- Anyone have any ADS simulation tutorials to share?

- The Xiaomi IoT module wifi version only costs 9.99 yuan. What would you most like to use it for?

- EEWORLD University ---- EDDP Motor Control Demonstration Platform Usage Guide

- SILICON LABS PG22-DK2503A EFM32PG22 Development Kit Unboxing Review

TC52N3844ECTRT

TC52N3844ECTRT

京公网安备 11010802033920号

京公网安备 11010802033920号