LinkSwitch-PH ICs enable the design of cost-effective, low-component-count LED drivers that meet power factor and harmonic limits while delivering an exceptional end-user experience. Features include an ultra-wide dimming range, flicker-free operation (even with low-cost AC input TRIAC dimmers), and fast, smooth turn-on.

The topology used is an isolated flyback operating in continuous conduction mode. Output current regulation is sensed entirely from the primary side, eliminating the need for secondary feedback components. No external current sensing is required on the primary side either, but rather is done inside the IC, further reducing components and losses. An internal controller adjusts the MOSFET duty cycle to keep the input current sinusoidal AC, ensuring high power factor and low harmonic currents.

The LNK406EG also offers a variety of sophisticated protection features, including automatic restart in the event of an open loop or output short circuit. Input overvoltage provides enhanced immunity to input faults and surges, output overvoltage protects the power supply when the load is disconnected, and precise hysteresis thermal shutdown ensures that the average PCB board temperature is within a safe range under all conditions.

In any LED lighting installation, the performance of the driver directly determines the end customer (user) experience of the lighting, including startup time, dimming, flicker, and consistency between drivers. The focus in this design is to be compatible with as many dimmers as possible and as wide a dimming range as possible under 115 VAC and 230VAC conditions. Even so, the two single input voltage operating ranges can still achieve design simplification, including applications where dimming is not required or the dimming range of the dimmer (high quality) is limited.

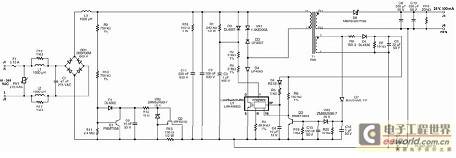

1. Circuit Schematic Diagram

Figure 1 Circuit diagram

2. Circuit Analysis

LinkSwitch-PH is an integrated controller and 725 V MOSFET device for LED driver applications. LinkSwitch-PH uses a single-stage continuous conduction mode flyback topology to provide a primary-side regulated constant current output while maintaining high power factor from the AC input.

1. Input filtering

Fuse F1 provides protection in the event of component failure, while RV1 is used to clamp the maximum voltage that may occur during differential mode surge testing. RV1 is rated for 275 VAC, which is slightly higher than the maximum specified operating voltage of 265 VAC. Diode bridge BR1 rectifies the AC line voltage, and capacitor C2 provides a low impedance path (decoupling) for the primary switching current. To maintain a power factor above 0.9, it is necessary to ensure a low capacitance (total of C1, C2, and C11). EMI filtering is provided by inductors L1-L3, C1, and C7 with Y1 safety requirements. Resistors R16 and R17 across L1 and L2 suppress the resonance between the input inductance, capacitance, and AC input impedance that typically occurs in conducted EMI measurements.

2. LinkSwitch-PH Primary

The transformer (T1) is connected to the DC bus at one end and to the drain pin of the LinkSwitch-PH at the other end. During the on-time of the MOSFET, the current in the primary winding rises and the stored energy is then transferred to the output during the off-time of the MOSFET. The RM8 core was chosen because it takes up very little area on the board. Flying leads are used to terminate the secondary winding into the PCB board because the bobbin does not meet the safety creepage distance requirement of 6.2 mm under 230 VAC operating conditions.

To provide U1 with peak input voltage information, the rectified AC input charges C3 through D2. Current then flows through R2 and R3 and is injected into the V pin of U1. Resistor tolerances will cause the V pin current to vary between power supplies, so choosing resistors with 1% tolerance minimizes this variation. The V pin current is also used by the device to set the input overvoltage and undervoltage protection thresholds. Undervoltage protection ensures that different power supplies start up at the same input voltage, and overvoltage protection allows the rectified line voltage to withstand (during surges and line voltage swells) up to the internal MOSFET's rated 725 BVDSS. Resistor R1 provides a discharge path for C3 with a time constant much greater than the discharge time of the rectified AC to prevent the V pin current from being modulated by the line voltage frequency.

The V pin current and the FB pin current are used internally to control the average LED output current. For phase angle dimming applications, a 49.9 kΩ resistor and a 4 MΩ (R2+R3) resistor can be used on the R pin (R4) and V pin, respectively, to maintain a linear relationship between the input voltage and the output current, thereby achieving the maximum dimming range. Resistor R4 also sets the internal line voltage input rise, fall, and input overvoltage protection thresholds.

During the MOSFET on-time, diode D3 and VR1 clamp the drain voltage to a safe level due to the effects of leakage inductance. Diode D4 is required to prevent reverse current from flowing through U1 when the voltage on C2 drops below the reverse output voltage (VOR). A Schottky barrier diode was chosen to reduce losses in this component and improve efficiency, but an ultrafast PN type diode (UF54002) can also be used instead to reduce cost.

Diode D6, C5, R7, and R8 form the primary bias supply, which is powered by the transformer's auxiliary winding. Capacitor C4 locally decouples U1's BP pin, which is the supply pin for the internal controller. During startup, an internal high-voltage current source connected to the DRAIN pin charges C4 to approximately 6 V. At this point, the device begins switching, and the device supply current is again provided by the bias supply through R5. Diode D5 isolates the BP pin from C5 to prevent the startup time from being extended by charging C4 and C5. It is recommended to use an external bias supply (through D5 and R5) to achieve the lowest device power dissipation and highest efficiency, although these components can be omitted if desired. This self-powered capability provides better phase-angle dimming performance because the IC can still operate normally when the input conduction phase angle is small, resulting in a low equivalent input voltage. Capacitor C4 is also used to select the output power mode, and selecting 10 μF (low power mode) minimizes device power dissipation and reduces the need for a heat sink.

3. Feedback

The bias winding voltage is used to indirectly reflect the output voltage without the need for secondary-side feedback components. The voltage on the bias winding is proportional to the output voltage (determined by the turns ratio between the bias winding and the secondary winding). Resistor R6 converts the bias voltage into a current that is injected into the feedback (FB) pin of U1. The internal control circuit in U1 combines the FB pin current, the V sense pin current, and the drain current information to provide a constant output current over a 2:1 output voltage range while maintaining a high input power factor. To limit the output voltage when no load is applied, D7, C12, R20, VR3, C13, Q3, and R19 form an output overvoltage clamp. If the output load is disconnected, the bias voltage will increase until VR3 turns on, which turns on Q3 and reduces the current into the FB pin. When this current falls below 20 μ, the device enters auto-restart mode and switching is disabled for 800ms, allowing the output voltage (and bias voltage) to decrease.

4. Output Rectification

The transformer secondary winding is rectified by D8 and filtered by C8 and C10. Schottky barrier diodes are selected for efficiency, and the combined values of C8 and C10 are chosen to give an LED ripple current equal to 40% of the average value. If a lower ripple design is desired, the output capacitor value can be increased. R15 acts as a small dummy load to limit the output voltage under no-load conditions.

5. Compatibility of thyristor phase dimming control

To provide output dimming requirements with low-cost thyristor leading-edge phase-controlled dimmers, we need to make comprehensive trade-offs during design.

Since LED lighting consumes very little power, the current consumed by the entire fixture is less than the holding current of the thyristor in the dimmer. This can cause some undesirable conditions, such as limited dimming range and/or flickering, due to inconsistent thyristor firing. Since LED lamps have relatively high impedance, when the thyristor turns on, the inrush current charges the input capacitor, causing severe ringing. This can also cause similar undesirable conditions, as the ringing causes the thyristor current to drop to zero and turn off.

To overcome these problems, two circuits are added—an active damping circuit and a passive bleeder circuit. The disadvantage of these circuits is that they increase power dissipation, which reduces the efficiency of the power supply. For non-dimming applications, these components can be omitted.

The active damping circuit consists of components R9, R10, R11, R12, D1, Q1, C6, VR2, Q2, and R13. This circuit limits the inrush current that flows into C2 and charges it when the thyristor is turned on. This is achieved by placing R13 in series within 1 ms before turn-on. After about 1 ms, Q2 turns on and shorts R13. This keeps the power dissipation in R13 low, allowing a larger value to be used when current limiting. Resistors R9, R10, R11, and C6 provide a 1 ms delay after the thyristor turns on. Transistor Q1 discharges C6 when the thyristor is not conducting, VR2 clamps the gate voltage of Q2 at 15 V, and R12 prevents the MOSFET from oscillating.

The passive bleeder circuit is composed of C11 and R18. This makes the input current always greater than the holding current of the thyristor, and the input current corresponding to the driver will increase in each AC half cycle to prevent the thyristor switching oscillation at the beginning of each conduction angle.

This design allows flicker-free dimming and has been tested with all phase angle dimmers, including those manufactured in Europe, China and Korea, and both leading and trailing edge types.

UPC451GR(5)-9LG-E1-A

UPC451GR(5)-9LG-E1-A

京公网安备 11010802033920号

京公网安备 11010802033920号