In 2020, NB-IoT deployment and application are accelerating, and NB-IoT technology is gaining more and more industry recognition. Relying on its long-term technical accumulation and successful experience in large-scale SOC chip design, based on its understanding of the actual needs of industry customers and the challenges faced by IoT chips, Core Image Semiconductor launched an innovative product to solve several types of problems that industry customers are generally concerned about. In a market environment where MCU product delivery times are prolonged and prices are rising, Core Image Semiconductor's LH3200 built-in independent open Open CPU completely replaced the external MCU of the original IoT solution in the trial commercialization, helping customers reduce costs and improve efficiency. It also proves that the built-in independent Open CPU of the NB-IoT SoC chip can replace the MCU in the design of IoT terminals.

When it comes to NB-IoT, from standards to chips and modules, to devices, networks, platforms and industry solutions, NB-IoT technology is dominated by the Chinese industry chain and has been widely recognized and supported by the global industry chain. As far as LPWA (Low Power Wide Area Network) is concerned, NB-IoT is the best technology choice on the market - NB-IoT can make full use of the operator's existing 4G infrastructure, improve network utilization and output, and enable new growth for operators; it can also make full use of the current industry scale and mature technology of NB-IoT to accelerate the process of Internet of Everything and digital transformation.

NB-IoT also gives related industries the confidence to adopt 3GPP technology, meeting the industry market's development needs for accelerated deployment and optimized performance - the 3GPP system is a technology system that can evolve and upgrade sustainably. As 2G networks are gradually reduced in frequency and decommissioned, most of the massive 2G IoT terminals will be replaced by NB-IoT terminals.

Regarding the development of NB-IoT in China, during the Huawei NB-IoT Billion Development Industry Summit held at the Beijing National Convention Center in October 2020, the China Academy of Information and Communications Technology (CAICT) gave exciting data: The development of NB-IoT in China has accelerated, and a 4+7+N development echelon has been formed: 4 tens of millions of applications, including: tracking applications represented by smart remote gas meters, water meters, smart smoke detectors, and electric vehicles; 7 million-level applications, including: white appliances, street lights, door locks, parking, tracking, agriculture, and electricity meters; and more emerging applications, such as POS machines, set-top boxes, trash cans, cold chain logistics, and smart factory mold management.

Currently, NB-IoT smart remote water meters, gas meters, heat meters and NB-IoT non-public electricity meters are the most mature and largest applications. Many metering solution manufacturers have developed various types of NB-IoT smart remote metering solutions based on existing technologies. Different technical routes have their own advantages and disadvantages, which are not described in detail, but all solutions should pay attention to the following points:

1. Communication performance, which requires strong communication capability, excellent performance, and stable performance;

2. In terms of energy saving, the power consumption must be low enough so that one battery can support at least several years of use and there is no need to manually replace the battery during its life cycle;

3. Stable work, high online rate and high copying success rate;

4. Solution cost. In the environment where MCU is in short supply worldwide and major manufacturers are raising prices, how can we make a smart remote meter solution with excellent performance at a lower cost?

5. It is highly intelligent and can autonomously monitor and report battery life. If necessary, it can effectively help water companies carry out preventive maintenance in advance, thereby improving service levels and customer satisfaction.

Smart meter solution manufacturers generally have high hopes for NB-IoT chips, hoping that they can help create better industry solutions and products with higher integration, better performance and more complete design.

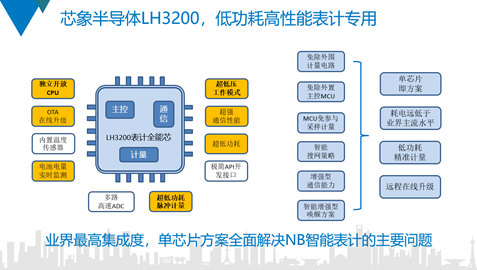

Core Image Semiconductor LH3200 NB-IoT chip is just such a product. The new generation of fully integrated NB-IoT terminal chip LOHALINK LH3200 is an innovatively designed NB-IoT communication chip that supports 3GPP R14 communication standards, has ultra-high integration, and integrates baseband processor BP, power management unit PMU, RF unit, universal ADC (6-channel, 10-bit), temperature sensor, etc. on a single chip. In addition, the chip has a built-in independent open application processor (open CPU).

Relying on its long-term accumulation in digital-analog hybrid ultra-low power design, 3GPP system architecture design, and communication chip design, the Xinxiang Semiconductor technology team launched this innovatively designed NB-IoT chip in 2020. During the chip design stage, Xinxiang Semiconductor worked closely with downstream meter solution designers to fully understand the actual needs of customers and the challenges faced by IoT chips. Combining the team's successful experience in designing multiple heterogeneous multi-core and SDR architecture large-scale SoC chips, this highly integrated, high-performance, and easy-to-use product was completed. LH3200 has the following features:

1. Low-voltage working mode: LH3200 can work normally at a supply voltage of 1.92V. When the power supply voltage drops sharply due to the insufficient instantaneous power supply capacity of the energy battery in high-current driving scenarios such as meter data uploading and valve control mechanism operation, it can effectively improve the stability of the meter solution;

2. Ultra-high receiving sensitivity: -118dBm receiving sensitivity. When the network coverage is not perfect and the signal is poor in many application scenarios, the meter solution based on LH3200 has stronger adaptability to the network environment;

3. Ultra-low power consumption: PSM 0.9 microamperes, 23dBm transmission 240mA, ensuring that the battery life meets industry requirements;

4. Higher transmit power: The maximum transmit power can reach 25dBm, which can make up for the limited uplink communication caused by insufficient network coverage;

5. LH3200 has a built-in ultra-low power pulse counter, which can count continuously for 7 x 24 hours at 0.9uA micro-power consumption without the need for MCU operation. Therefore, the metering solution based on LH3200 can be called an energy-saving expert in pulse meters; the ultra-low power metering function can significantly reduce the average power consumption of smart meter products and extend battery life. The built-in metering unit of LH3200 adopts a variety of anti-misjudgment, filtering and anti-interference mechanisms, and still maintains extremely high metering accuracy at extremely low power consumption.

6. High-precision battery monitoring: The battery voltage can be continuously monitored with an accuracy of 0.1V, so that the cloud can understand the battery life of the IoT terminal at any time, allowing the operator to perform preventive maintenance more efficiently.

7. The built-in independent open Open CPU can completely replace the external MCU in the dual-chip architecture of traditional IoT terminals, and is physically isolated from the NB-IoT communication CPU, ensuring that the physical resources available to users are independent, safe, efficient and reliable.

With its innovative design and excellent performance, in just over half a year, the LH3200 chip of Core Image Semiconductor has been applied in many fields: a shared device commercial application (a long connection application that requires real-time response to user requirements, low power consumption and low cost), a metering equipment application, a smart lock project application, etc. More applications are ready to be launched, rapidly expanding the application scope of LH3200.

It is particularly worth mentioning that in this special period of tight global MCU supply, the built-in Open CPU of Coreimage LH3200 has demonstrated its capabilities in practical applications.

Over the past year, the COVID-19 pandemic has had a huge impact on the global economy, and the global MCU market has also been hit. The extended delivery time of MCU products has led to an imbalance between supply and demand. The industry has widely reported on delayed MCU delivery and price increases. Many well-known professional media have discussed how to use IoT chips with built-in Open CPU to help the IoT industry and solve the urgent needs of the industry.

Since the third quarter of last year, the built-in independent Open CPU of Core Image Semiconductor's LH3200 has been stably running user applications on-site in a commercial project, saving the customer an additional MCU, which not only reduced material and production costs, but also shortened the product development cycle.

This is another commercial scenario for LH3200 from Core Image Semiconductor since its mass production and supply, and it is also the first commercial application in the long-connection shared device scenario. The company's R&D team worked closely with customers to quickly and successfully implement all the original customer solutions. The LH3200's built-in independent Open CPU has fully assumed the operation of customer applications, and the on-site operation is stable and reliable. The solution implementation, on-site test tuning and stable operation performance far exceeded customer expectations and won the praise of customers.

Although the existing network coverage is not perfect and the signal is not stable, the LH3200 of Core Image Semiconductor maintains a stable connection at a signal strength of -118dBm, which also exceeds the customer's expectations. This shows that this chip of Core Image Semiconductor not only has excellent communication performance, but also proves one thing for the industry through field actual combat testing - the built-in independent Open CPU of the NB-IoT SoC chip can replace the MCU in the design of the IoT terminal, saving costs for customers and improving efficiency.

Previous article:GigaDevice GD32 joins hands with Microsoft Azure to build a new IoT cloud platform

Next article:Edge computing starts the chip war

- Popular Resources

- Popular amplifiers

- e-Network Community and NXP launch Smart Space Building Automation Challenge

- The Internet of Things helps electric vehicle charging facilities move into the future

- Nordic Semiconductor Launches nRF54L15, nRF54L10 and nRF54L05 Next Generation Wireless SoCs

- Face detection based on camera capture video in OPENCV - Mir NXP i.MX93 development board

- The UK tests drones equipped with nervous systems: no need to frequently land for inspection

- The power of ultra-wideband: reshaping the automotive, mobile and industrial IoT experience

- STMicroelectronics launches highly adaptable and easy-to-connect dual-radio IoT module for metering and asset tracking applications

- This year, the number of IoT connections in my country is expected to exceed 3 billion

- Infineon Technologies SECORA™ Pay Bio Enhances Convenience and Trust in Contactless Biometric Payments

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Sandia Labs develops battery failure early warning technology to detect battery failures faster

- FPGA Implementation of Light Band Centerline Extraction in 3D Scanning Images

- Help, looking for a schematic diagram of asm1142

- RT-Thread system solves the problem that low-priority tasks cannot be suspended with high-priority tasks

- Automatically load Cadence Toolbox functional components

- Let's read together! ——Power supply design book recommendations

- EEWORLD University Hall----Live Replay: Introduction to Jacinto?7 Industrial Application Processor

- [Repost] How to quickly distinguish common SMT patch components

- MOS tube power supply problem

- Use of TI DSP Integrated Development Environment CCS

- Learn MSP430F5529 programming routine 1

HI-8573PSIF

HI-8573PSIF

京公网安备 11010802033920号

京公网安备 11010802033920号