Basic summary of MOS tube drive circuit

Source: InternetPublisher:司马缸砸光 Keywords: Analog circuit mos tube drive circuit Updated: 2020/01/30

Detailed explanation of MOS tube drive circuit

When using MOS tubes to design switching power supplies or motor drive circuits, most people will consider the on-resistance, maximum voltage, maximum current, etc. of the MOS tube, and many people only consider these factors. Such a circuit may work, but it is not excellent and is not allowed as a formal product design.

The following is the editor's summary of the basics of MOS and MOS drive circuits. It refers to some information and is not original. Including the introduction, characteristics, driving and application circuits of MOS tubes.

A type of MOSFET tube FET (the other is JEFT), which can be made into enhancement mode or depletion mode, P channel or N channel, a total of 4 types, but in actual application only enhancement mode N channel MOS tubes are used and enhancement-type P-channel MOS transistors, so the commonly mentioned NMOS or PMOS refers to these two types.

As for why the depletion type MOS tube is not suitable, it is not recommended to get to the bottom of it.

For these two types of enhanced MOS tubes, NMOS is more commonly used. The reason is that the on-resistance is small and easy to manufacture. Therefore, NMOS is generally used in switching power supply and motor drive applications. In the following introduction, NMOS is mostly used.

There is parasitic capacitance between the three tubes of the MOS tube. This is not what we need, but is caused by the limitations of the manufacturing process. The existence of parasitic capacitance makes it more troublesome when designing or selecting the drive circuit, but there is no way to avoid it. More details later.

On the MOS tube schematic diagram, you can see that there is a parasitic diode between the drain and the source. This is called a body diode. This diode is very important when driving inductive loads (such as motors). By the way, the body diode only exists in a single MOS transistor and is usually not found inside an integrated circuit chip.

MOS tube conduction characteristics

Conducting means acting as a switch, which is equivalent to the switch being closed.

The characteristic of NMOS is that it will turn on when Vgs is greater than a certain value. It is suitable for the case where the source is grounded (low-end drive), as long as the gate voltage reaches 4V or 10V.

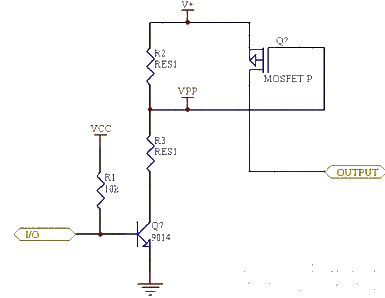

The characteristics of PMOS are that it will turn on when Vgs is less than a certain value, which is suitable for situations where the source is connected to Vcc (high-end drive). However, although PMOS can be easily used as a high-end driver, due to reasons such as large on-resistance, high price, and few replacement types, NMOS is usually used in high-end drivers.

MOS switch tube loss

Whether it is NMOS or PMOS, there is an on-resistance after it is turned on, so a little current will consume energy on this resistor. This part of the energy consumed is called conduction loss. Choosing a MOS tube with a small on-resistance will reduce the conduction loss. The on-resistance of current low-power MOS tubes is generally around tens of millivolts, and there are also several milliohms.

When MOS is turned on and off, it must not be completed instantly. The voltage at both ends of the MOS has a decreasing process, and the flowing current has an increasing process. During this period, the loss of the MOS tube is the product of the voltage and the current, which is called switching loss. Usually switching losses are much larger than conduction losses, and the faster the switching frequency, the greater the losses.

The product of voltage and current at the moment of conduction is very large, causing great losses. Shortening the switching time can reduce the loss during each turn-on, and reducing the switching frequency can reduce the number of switches per unit time. Both methods can reduce switching losses.

MOS tube drive circuit

Compared with bipolar transistors, it is generally believed that no current is required to turn on a MOS transistor, as long as the GS voltage is higher than a certain value. This is easy to do, but we also need speed.

It can be seen in the structure of the MOS tube that there is a parasitic capacitance between GS and GD, and the driving of the MOS tube is actually the charging and discharging of the capacitor. Charging the capacitor requires a current, because the capacitor can be regarded as a short circuit at the moment of charging, so the instantaneous current will be relatively large. The first thing to pay attention to when selecting/designing a MOS tube driver is the amount of instantaneous short-circuit current it can provide.

The second thing to note is that the gate voltage of NMOS, which is commonly used for high-side driving, needs to be greater than the source voltage when turned on. When the high-end drive MOS tube is turned on, the source voltage and drain voltage (Vcc) are the same, so the gate voltage is 4V or 10V greater than Vcc. If you want to get a voltage larger than Vcc in the same system, you need a special boost circuit. Many motor drivers have integrated charge pumps. It should be noted that an appropriate external capacitor should be selected to obtain sufficient short-circuit current to drive the MOS tube.

The 4V or 10V mentioned above is the turn-on voltage of commonly used MOS tubes. Of course, a certain margin needs to be allowed during design. And the higher the voltage, the faster the conduction speed and the smaller the conduction resistance. Now there are MOS tubes with smaller conduction voltages used in different fields, but in 12V automotive electronic systems, generally 4V conduction is enough.

For the MOS tube drive circuit and its losses, you can refer to Microchip's AN799 matching MOSFET Drivers to MOSFETs, which is described in detail, so I won't write more.

MOS tube application circuit

The most significant characteristic of MOS tubes is their good switching characteristics, so they are widely used in circuits that require electronic switches, such as switching power supplies and motor drive circuits, as well as lighting dimming.

Current MOS drivers have several special requirements:

1. Low voltage applications

When using a 5V power supply, if a traditional totem pole structure is used at this time, since the voltage drop of the transistor is only about 0.7V, the actual final voltage loaded on the gate is only 4.3V. At this time, we choose the nominal gate voltage of 4.5V MOS tubes have certain risks. The same problem also occurs when using 3V or other low-voltage power supplies.

2. Wide voltage application

The input voltage is not a fixed value, it will change with time or other factors. This change causes the driving voltage provided by the PWM circuit to the MOS tube to be unstable.

In order to make MOS tubes safe under high gate voltage, many MOS tubes have built-in voltage regulator tubes to forcibly limit the amplitude of the gate voltage. In this case, when the provided driving voltage exceeds the voltage of the voltage regulator tube, it will cause large static power consumption.

At the same time, if you simply use the principle of resistor dividing to reduce the gate voltage, it will happen that when the input voltage is relatively high, the MOS tube works well, but when the input voltage decreases, the gate voltage is insufficient, causing incomplete conduction, thereby increasing power consumption. .

3. Dual voltage application

In some control circuits, the logic part uses a typical 5V or 3.3V digital voltage, while the power part uses 12V or even higher voltages. The two voltages are connected to a common ground.

This puts forward a requirement to use a circuit so that the low-voltage side can effectively control the MOS tube on the high-voltage side. At the same time, the MOS tube on the high-voltage side will also face the problems mentioned in 1 and 2.

In these three cases, the totem pole structure cannot meet the output requirements, and many off-the-shelf MOS driver ICs do not seem to include gate voltage limiting structures.

- What is a pure resistance circuit? What is a pure resistance AC circuit?

- Analysis of the basic principle of measuring resistance by bridge method

- Capacitance detection circuit configuration, how to deal with low frequency and high frequency noise?

- Analysis of the working principle of CMOS/CCD image sensor

- What are the classifications of filters?

- What are the parts of the fpga design process

- How to Build a Simple Temperature Indicator Circuit Using NTC and PTC Thermistors

- Why use PWM? What are its advantages?

- Star finder battery indicator circuit

- Presettable 8-bit counter circuit

- Comprehensive understanding of the principles and applications of ESD protection structures in cmos circuits

- Working principle diagram and application diagram of silicon controlled thyristor

- The principle of D/A conversion using resistors

- Basic circuit of differential amplifier circuit

- Collection of integrated operational amplifier circuit diagrams

- The basic definition of arithmetic circuits and the classic basic circuit diagram of arithmetic circuits

- Internal block diagram of PS501

- Biased push-pull power amplifier circuit

- IGBT working principle diagram

- Police car sound and light analog circuit

京公网安备 11010802033920号

京公网安备 11010802033920号