In recent years, the Metaverse has been like a hot wind, blowing up countless people's imagination of "technology, fantasy and the future". With the popularity of the Metaverse, AR and VR devices, as its hardware carriers, have become one of the important areas of technological innovation. Augmented Reality (AR) refers to the technology that allows the virtual world on the screen to combine and interact with the real world scene through the position and angle calculation of the camera image and the addition of image analysis technology.

AR technology mainly includes four parts: hardware, software, content and platform. In this article, the focus is on the light source used for the display light machine of the main hardware part. Before entering the formal content, let's imagine what characteristics we want AR glasses to have if we want them to be as realistic as the science fiction in the movies? First of all, the technology should achieve a complete fusion of virtual and real, and secondly, the appearance should be the same as ordinary glasses. To achieve these two points, dozens of factors such as weight, ergonomics, high efficiency, etc. are involved. Display technology is the key breakthrough in these difficulties.

What are the display technologies used in mainstream AR glasses?

The mainstream display technologies currently used for AR glasses can be divided into passive micro-display technology, active micro-display technology and scanning display technology.

Passive microdisplay technology

Passive micro-display technologies include traditional LCD, DLP, LCOS, etc., which need to use RGB LED or RGB laser as light source when working. Passive micro-display technology is quite mature in the market. It can achieve advantages such as high brightness and high color gamut, but the size of the optical machine is relatively large compared to other micro-display technologies, and the light spread is limited.

2. Active microdisplay technology

Active micro-display technology includes display technologies using Micro OLED and Micro LED. Micro OLED, also known as silicon-based OLED, has characteristics such as self-luminescence and is more suitable for use in VR glasses. If a Micro OLED display is used in an AR device, the display effect will be greatly reduced in bright scenes. The main reason is that the current mainstream Micro OLED display technology can only reach a brightness of 1000-6000 nits, and the final eye brightness may be only 200-300 nits. Micro LED has better performance in efficiency, brightness, and color gamut contrast. However, due to the great difficulty of RGB integration, the application of this technology still has many challenges.

3. Scanning display technology

The scanning display technology (LBS) uses RGB laser as the light source and is matched with MEMS for scanning imaging. It has the advantages of small size, high efficiency, high color gamut and high contrast, but the system design is relatively complex, and the interference effect of the laser will cause speckle phenomenon, so the image quality of LBS technology needs to be improved.

AR optical machine design requires "trade-offs"

In AR virtual information display, the displayed information needs to be constantly adjusted and adapted according to the movements of the glasses wearer, and superimposed on what the user actually sees in the real world. The computer needs to detect the environment through cameras, GPS positioning or sensor data, and select the information to be displayed. Therefore, when designing, engineers have to consider many factors including weight, ergonomics, display brightness, cost, etc. The various factors interact with each other, and at our current level of technology, it is difficult to fully meet all requirements. We have to set different priorities based on demand and decide on the relevant display solutions (i.e. light source and optical solutions).

As a global leader in optical solutions, ams Osram has a variety of LEDs that provide light sources for AR optical machines. Among them, in the dichroic mirror solution, ams Osram provides red and blue two-in-one LED-LE BR Q7WM.02, single green LED-LE T Q8WM, and converted green light LED-LCG H9RM. In the light guide solution, it provides LED-LE RTB N7WM, which integrates three RGB chips in one package and is combined with a light guide to realize lighting scenes.

In AR, dichroic mirrors and light guides are both commonly used light combining solutions. Generally speaking, the dichroic mirror solution can collect more light energy, so it has better color uniformity and can achieve higher display brightness. However, the dichroic mirror solution requires more optical devices, which will lead to a larger size of the optical machine and also have strict requirements on assembly accuracy. The light guide solution does not require many dichroic mirrors, so the assembly accuracy is lower and the size of the optical machine is relatively small, but due to the arrangement, the LED light energy that can be used by the display is lower, and the color uniformity will also be poor due to differences in the arrangement position.

In order to improve color uniformity, ams OSRAM launched the "田"-shaped LED-MOSAIC based on the original "一"-shaped arrangement of three RGB chips. It includes a version with four RGGB chips and a version with six RRGGBB chips. Compared with the original "一"-shaped arrangement, this arrangement not only improves color uniformity, but also further reduces the distance between the chip surface and the package surface (from the original 0.44mm to 0.15mm), which means that the optics are closer to the chip, making it easier to collect light and more uniform in color.

So what kind of display brightness can this solution achieve?

Taking the AR display brightness based on RGGB MOSAIC as an example, when the LED power is 1W, the output luminous flux is about 50lm. After passing through the front-end optical system, 10% to 20% can be output, that is, the luminous flux will be maintained at 5 to 10lm before reaching the optical waveguide lens. Matching different optical waveguide types can achieve eye-catching brightness of 350nits to 6500nits.

Using MOSAIC LED with LCOS or DLP can reduce the size of the optical machine to 3-5 cc (cubic centimeters), which is a significant reduction in size and weight compared to the 5-10cc optical machine volume of the traditional LED + dichroic mirror solution. Nevertheless, for ordinary consumer AR, such a volume is still not ideal, and the size needs to be further reduced. As a result, ams OSRAM has developed an RGB integrated laser suitable for laser beam scanning (LBS) technology. Using this laser with MEMS, the volume of the entire optical machine can be reduced to less than 1cc, which is a great boost for ordinary consumer AR glasses.

New R/G/B laser module

The three most important elements in the LBS solution are RGB laser, beam shaping optics and scanning mirror(s). The principle is that after the RGB laser is emitted from the laser module, it is collimated and combined by optical components before reaching the MEMS mirror, and then reflected by the MEMS mirror and coupled into the optical waveguide. The optical waveguide is like the lens of ordinary glasses. The image will be transmitted in the optical waveguide and finally projected to the user's eyes.

LBS technology itself is not a brand new display technology. The optical machine size of the three separate R/G/B TO38 lasers used in the early days was relatively large, about 1.7cc, and the optical machine designed based on the three-in-one RGB laser (VEGALAS RGB) launched by ams OSRAM can further reduce the size to 0.7cc. The size of this laser is only 7×4.6×1.2 (mm3), and it can be directly made into SMD patches. And the airtight packaging design is used to prevent the blue laser, in particular, from being affected by the external environment, thereby greatly improving the reliability. One point that needs to be emphasized is that since this laser does not yet have integrated beam shaping optics, beam collimation and beam combining need to be implemented outside the package.

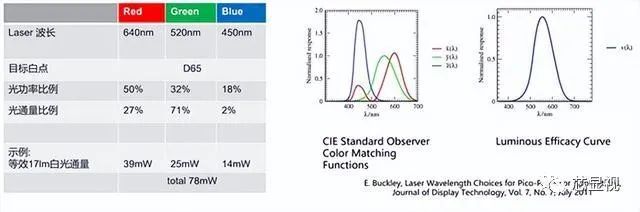

How does the VEGALAS RGB-based optical display brightness correspond to the laser power? AMS OSRAM made such a simple estimate. Taking the target eye brightness of 1500nits as an example, the conversion rate of the optical waveguide is about 150nits/lm, so the luminous flux needs to be about 10lm before entering the optical waveguide. After the laser is shaped and combined by optical devices, it can generally achieve a light collection efficiency of more than 50%. We can calculate that the output luminous flux of the laser is required to be 17lm, and then convert it into the required optical power of the three colors. The total optical power required is about 78mW, and then calculated based on the electro-optical conversion efficiency that each chip can currently achieve, it is about 0.8W of electrical power input.

Through the wavelength, target white point, and equivalent white light flux @ target white point of the RGB laser, it can be calculated that the red chip needs to output 39mW of optical power, the green needs 25mW of optical power, and the blue needs 14mW of optical power. This is the source of the total optical power requirement of 78mW.

The future: Multi-Beam Scanning

In order to make AR glasses smaller, thinner and lighter, they can reach the consumer-grade technical level. In addition to the VEGALAS RGB three-in-one laser currently under development, the beam scanning solution can also be expanded, that is, multi-beam scanning (Multi-Beam Scanning, MBS for short). For example, we can make multiple emission points based on one emission point of a green laser, so as to obtain higher and denser scanning point pixels, which can effectively improve the resolution and uniformity of the entire display. But at present, multi-beam scanning technology is relatively difficult to implement, and there is still a long way to go if it is to be truly commercialized. However, ams OSRAM is fully prepared for this and is committed to bringing consumers an "all-encompassing" visual experience in the virtual and real worlds.

Previous article:What are smart wearables? What products does smart wearables include?

Next article:Making dynamic monitoring ubiquitous - Performance analysis of medical-grade Bluetooth data gateway

- Popular Resources

- Popular amplifiers

- Red Hat announces definitive agreement to acquire Neural Magic

- 5G network speed is faster than 4G, but the perception is poor! Wu Hequan: 6G standard formulation should focus on user needs

- SEMI report: Global silicon wafer shipments increased by 6% in the third quarter of 2024

- OpenAI calls for a "North American Artificial Intelligence Alliance" to compete with China

- OpenAI is rumored to be launching a new intelligent body that can automatically perform tasks for users

- Arm: Focusing on efficient computing platforms, we work together to build a sustainable future

- AMD to cut 4% of its workforce to gain a stronger position in artificial intelligence chips

- NEC receives new supercomputer orders: Intel CPU + AMD accelerator + Nvidia switch

- RW61X: Wi-Fi 6 tri-band device in a secure i.MX RT MCU

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- Hejian Gongsoft's New Year's greetings for 2022 - Spring brings blessings and everything is glorious

- How high can the transmission power of 5G mobile phones be?

- ESP32 uses littlefs v2 as the default file system

- Op amp power supply

- EEWORLD University ----TI EV/HEV 48V and Motor Drive Solutions

- FPGA Advanced Timing Synthesis Tutorial.pdf

- [GD32L233C-START Review] 6. Fingerprint Management System (2) - Added brightness adjustment

- [Sipeed LicheeRV 86 Panel Review] 15. lvgl calendar control and weather display

- [Project source code] BMP2mif file software, convenient for using ROM to store image data and display

- I want to control the on and off of NMOS through a 3.3V microcontroller

TC52N3643ECTRT

TC52N3643ECTRT

京公网安备 11010802033920号

京公网安备 11010802033920号