In a switching circuit, each PIN diode has an accompanying PIN diode driver or switch driver that provides a controlled forward bias current, reverse bias voltage, and an activation interface between a control signal (usually a digital logic command) and one or more PIN diodes. Depending on the application, this driver function can be implemented using a discrete design or a dedicated IC.

On the other hand, as an alternative, readily available op amps and specialty amplifiers such as clamp amplifiers and differential amplifiers can be used to replace discrete PIN diode drive circuits and expensive PIN diode driver ICs. Such op amps have wide bandwidth, high slew rate, and ample steady-state current to drive PIN diodes. This article discusses three different PIN driver circuits that use op amps or specialty amplifiers: the AD8037, AD8137, and ADA4858-3. These circuits are designed for single-pole double-throw (SPDT) PIN diode switches, but they can also be modified to suit other circuit configurations. Before describing these circuits in detail, this article will first discuss the characteristics and uses of PIN diodes.

PIN diode

PIN diodes are used as current-controlled resistors, operating at RF and microwave frequencies, with a resistance of only a fraction of an ohm when forward biased ("on") and a resistance of more than 10 kΩ when reverse biased ("off"). Unlike typical PN junction diodes, PIN diodes have an additional layer of high-resistance intrinsic semiconductor material (represented by the "I" in PIN) between the P and N regions, as shown in Figure 1.

Figure 1. PIN diode

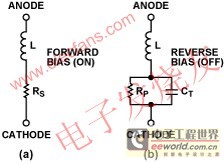

When a PIN diode is forward biased, holes from the P material and electrons from the N material are injected into the I region. The charges do not recombine instantly; the finite amount of time required for the charges to recombine is called the “carrier lifetime.” This results in a net stored charge in the I region, so its resistance drops to a value called the effective on-resistance, RS, of the diode (Figure 2a).

When a reverse or zero bias voltage is applied, the diode presents a large resistance, RP, in parallel with a capacitance, CT (Figure 2b). By varying the diode geometry, PIN diodes can be made with different combinations of RS and CT to suit a variety of circuit applications and frequency ranges.

Figure 2. PIN diode equivalent circuit: a) on, IBIAS >> 0; b) off, VBIAS ≤ 0.

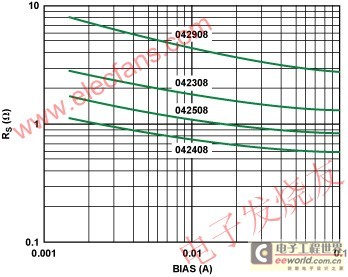

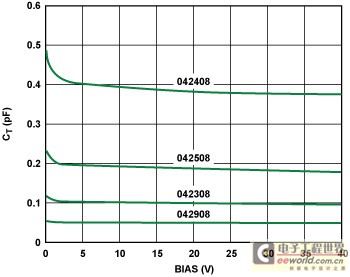

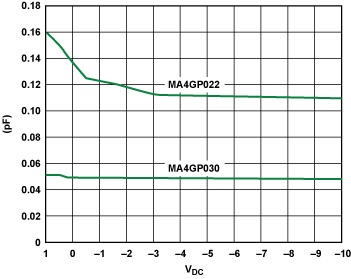

The steady-state bias current ISS and the reverse voltage provided by the driver together determine the final values of RS and CT. Figures 3 and 4 show the parameter relationships for a typical PIN diode series, the M/A-COM MADP 042XX8-13060 series silicon diode. The diode material affects its characteristics. For example, gallium arsenide (GaAs) diodes require almost no reverse bias to achieve low CT values, as shown in Figure 9.

Figure 3. Relationship between on-resistance and forward current of silicon diode

Figure 4. Relationship between silicon diode capacitance and reverse voltage.

The charge stored in the PIN diode can be approximated using Equation 1.

(1)

in:

QS = Stored Charge

τ = diode carrier lifetime

ISS = Steady State Current

To turn the diode on or off, the stored charge must be injected or removed. The driver's job is to inject or remove the stored charge very quickly. If the switching time is less than the carrier lifetime of the diode, the peak current (IP) required to achieve fast switching can be approximated using Equation 2.

(2)

in:

t = required switching time

ISS = The steady-state current provided by the driver, which is used to set the PIN diode on-resistance RS

τ = carrier lifetime

The driver injection or removal current (or "spike current") i can be expressed as Equation 3.

(3)

in:

C = value of the driver output capacitance (or “spike capacitance”)

v = voltage across the output capacitor

dv/dt = the time rate of change of voltage across the capacitor

PIN diode bias interface

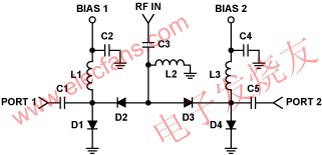

Connecting the switch driver control circuit to the PIN diodes to switch the diodes by applying forward or reverse bias is a challenging task. The bias circuit usually uses a low-pass filter, which is placed between the RF circuit and the switch driver. Figure 5 shows a single-pole double-throw (SPDT) RF switch and its bias circuit. When properly set up, filters L1/C2 and L3/C4 allow the control signal to be applied to the PIN diodes D1–D4 with minimal interaction with the RF signal (switching from RF IN to PORT 1 or PORT 2). These components allow relatively low-frequency control signals to pass through the PIN diodes, but prevent high-frequency signals from escaping the RF signal path. Unusual RF energy loss means that the insertion loss of the switch is too high. Capacitors C1, C3, and C5 prevent the DC bias applied to the diodes from intruding on the circuits in the RF signal path. Inductor L2 in the DC ground return allows DC and low-frequency switch driver signals to pass easily, but presents a high impedance to RF and microwave frequencies, reducing RF signal losses.

Figure 5. Typical single-pole double-throw (SPDT) RF switch circuit.

The bias circuit, RF circuit, and switch driver circuit all interact and affect each other's performance, so like all designs, it is important to consider various trade-offs. For example, larger C2 and C4 (>20 pF) are good for RF performance, but are troublesome for the driver because large capacitors result in slower rising and falling edges. Fast switching is beneficial for most applications; therefore, the capacitors must be extremely small for optimal driver performance, but large enough to meet RF circuit requirements.

Conventional PIN diode driver

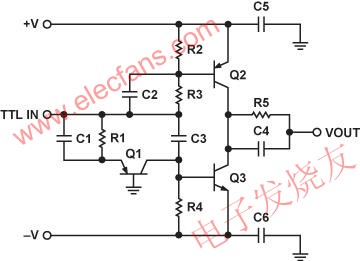

PIN diode drivers come in a variety of shapes and sizes. Figure 6 shows a schematic of a typical discrete switch driver that provides high switching speeds. This driver can be implemented using either a "chip-and-wire" (hybrid) structure, which is very expensive, or a "surface-mount" (SMT) device; the former is not expensive but requires more printed circuit board (PCB) area than the hybrid structure.

Figure 6. Discrete switch driver circuit.

There are also dedicated switch driver integrated circuits (ICs); these ICs are compact, offer TTL interfaces, and have good performance, but they have limited flexibility and tend to be expensive.

There is another switch driver architecture that should be considered, that is, using an operational amplifier. The obvious advantage of an op amp switch driver is its inherent flexibility, which can be easily configured to suit different applications, supply voltages and conditions, providing designers with a wealth of design options.

Operational Amplifier PIN Diode Driver

An attractive alternative to driving PIN diodes is an op amp circuit. In addition to flexibility, this circuit can often operate at transition speeds approaching or exceeding 1000 V/μs. Three different RF PIN diode amplifier driver circuits are described below. The amplifiers chosen differ in their fundamental characteristics but all perform similar functions. These amplifier circuits can drive either silicon or gallium arsenide (GaAs) PIN diodes, but each has its own characteristics.

AD8037—Clamp Amplifier

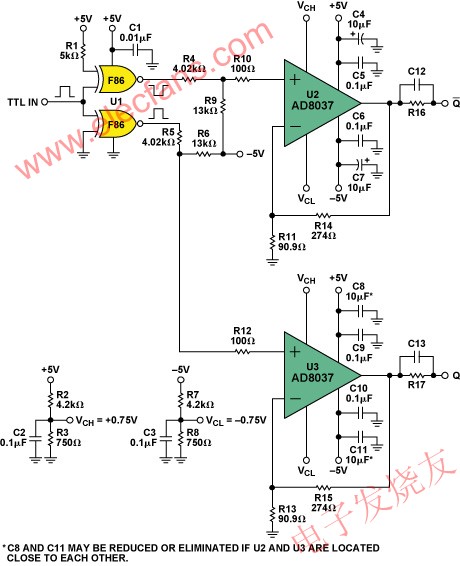

The circuit can operate at frequencies up to 10 MHz with excellent switching performance and a total propagation delay of 15 ns. The output voltage and current can be adjusted to suit different applications by changing the gain or clamp voltage.

The AD8037 clamp amplifier was originally designed to drive ADCs and provides a clamped output to protect the ADC input from overdrive. The configuration shown in Figure 7 uses a pair of AD8037s (U2 and U3) to drive a PIN diode.

Figure 7. AD8037 PIN diode driver circuit.

In this example, U2 and U3 are configured in a noninverting configuration for a gain of 4. Extremely clean and accurate clamping can be achieved by utilizing the unique input clamp feature of the AD8037. It linearly amplifies the input signal up to the gain times the positive and negative clamp voltages (VCH and VCL). With a gain of 4 and a clamp voltage of ±0.75 V, the output voltage is equal to 4 times the input voltage if the input voltage is less than ±0.75 V, and is clamped to a maximum of ±3 V if the input voltage is greater than ±0.75 V. This clamp feature allows very fast overdrive recovery (typically less than 2 ns). The clamp voltages (VCH and VCL) are determined by the voltage dividers R2, R3, R7, and R8.

The digital interface is implemented by a 74F86 XOR logic gate (U1), which provides the drive signals used by U2 and U3 with minimal propagation delay skew between the two complementary outputs. The resistor network R4, R5, R6, and R9 level shifts the TTL output to approximately ±1.2 V, which is then fed to U2 and U3 through R10 and R12.

The ±1.2-V inputs to U2 and U3 provide 60% overdrive to ensure that the outputs go into clamping (4 × 0.75 V). Therefore, the output levels of the silicon PIN diode drivers are set to ±3 V. Resistors R16 and R17 limit the steady-state current. Capacitors C12 and C13 set the peak current of the PIN diodes.

AD8137—Differential Amplifier

A differential amplifier, such as the AD8137 used in this example, provides excellent high-speed switching performance at a low cost and gives the designer great flexibility in driving various types of RF loads. A wide variety of differential amplifiers are available, including some that are faster and have higher performance.

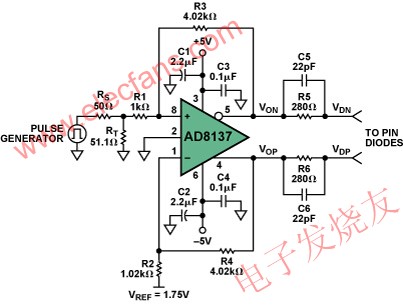

The AD8137 high speed differential amplifier is commonly used to drive ADCs, but can also be used as a low cost, low power PIN diode driver. Its typical switching time is 7 ns to 11 ns, including the propagation delays of the driver and RF load. It provides complementary outputs and is versatile enough to replace expensive traditional drivers.

The circuit shown in Figure 8 converts a single-ended TTL input (0 V to 3.5 V) to a complementary ±3.5 V signal while minimizing propagation delay. The TTL signal is amplified by a factor of 4 to produce the required ±3.5 V swing at the AD8137 output. The midpoint (or common-mode voltage) of the TTL signal is 1.75 V; this same voltage must be applied to R2 as the reference voltage, VREF, to avoid introducing common-mode offset errors at the amplifier output. It is best to drive this point from a low source impedance; any series impedance will be added to R1, affecting the amplifier gain.

Figure 8. PIN diode driver schematic.

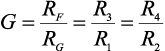

The output voltage gain can be calculated using Equation 4:

(4)

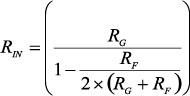

To properly terminate the pulse generator input impedance to 50 Ω, the input impedance of the differential amplifier circuit needs to be determined. This can be calculated using Equation 5, which gives RT = 51.55 Ω, with the closest standard 1% resistor value being 51.1 Ω. For symmetrical output swings, the impedance of both input networks must be the same. This means that the inverting input impedance must incorporate the Thévenin impedance of the source and the termination resistor into the gain setting resistor, R2. For more details, see Application Note AN-1026.

(5)

In Figure 8, R2 is approximately 20 Ω larger than R1 to compensate for the additional resistance (25 Ω) introduced by the parallel combination of the source resistance, RS, and the termination resistance, RT. R4 is set to 1.02 kΩ (the closest standard resistor value to 1.025 kΩ) to ensure that the two resistor ratios are equal and avoid introducing common-mode errors.

Output level shifting is easily accomplished using the AD8137’s VOCM pin, which sets the dc output common-mode level. In this example, the VOCM pin is tied to ground to provide a symmetrical output swing about ground.

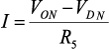

Resistors R5 and R6 set the steady-state PIN diode current, as shown in Equation 6.

(6)

Capacitors C5 and C6 set the spike current, which helps inject and remove the charge stored in the PIN diode. The values of these capacitors can be adjusted to optimize performance based on the specific diode load requirements. The spike current can be calculated using Equation 7.

(7)

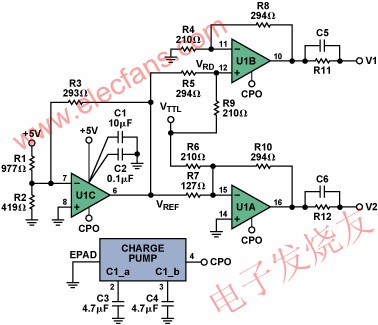

ADA4858-3 — Triple Operational Amplifier with Internal Charge Pump

Many applications only provide one power supply, which often makes circuit designers feel awkward, especially when low off capacitance is required in PIN circuits. In this case, silicon or GaAs PIN diode driver circuits can use operational amplifiers with on-chip integrated charge pumps, eliminating the need for an external negative supply; the benefit is significant space, power and budget savings.

The ADA4858-3, a high speed, current feedback, triple amplifier, is one such device that has excellent features, an on-chip charge pump, and an output swing of –3 V to –1.8 V below ground (depending on the supply voltage and load). This device is so robust that it can actually source up to 50 mA of negative supply current to other circuits.

The ADA4858-3 provides a unique solution to the problem of driving a complementary PIN diode microwave switch in a single-supply system. Looking back at Figure 4, it can be seen that even a small amount of reverse bias can help reduce the diode capacitance, CT, depending on the type of PIN diode. This type of driver is beneficial for GaAs PIN diodes, because these diodes generally do not require much negative bias to keep the off capacitance (CT) small (Figure 9).

Figure 9. GaAs CT capacitance vs. voltage

The circuit shown in Figure 10 uses the ADA4858-3 as a PIN diode driver. A buffer gate can be added at the input to make the circuit compatible with TTL or other logic. The requirement for this circuit is to convert the TTL 0V to 3.5V input signal swing to a complementary –1.5V to +3.5V swing for driving a PIN diode.

Figure 10. ADA4858-3 used as a PIN diode driver

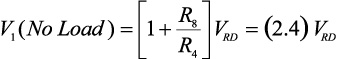

R1, R2, R3, and U1C form the –1.5V reference voltage for this circuit, and the internal negative voltage CPO is generated by the on-chip charge pump. Capacitors C3 and C4 are required for the charge pump to operate. The negative reference voltage is then passively combined with the VTTL input via a voltage divider (R5 and R9). The resulting voltage (VRD) appears at the noninverting input of U1B. The U1B output voltage can be calculated using Equation 8.

(8)

in:

(9)

The negative reference voltage is also fed to amplifier U1A where it is combined with the TTL input and the resulting output voltage V2 can be calculated using Equation 10.

(10)

These amplifiers use a current feedback architecture, so attention must be paid to the selection of the feedback resistor, which plays an important role in the stability and frequency response of the amplifier. For this application, the feedback resistor is set to 294 Ω, which is the value recommended by the data sheet. The output voltages V1 and V2 can be expressed by Equation 8 and Equation 10, respectively. The amount of output peak current can be determined using Equation 3 and the voltage across capacitors C5 and C6. The steady-state current that sets the PIN diode on-resistance is determined by the voltage difference across R11 and R12 and depends on the PIN diode curve and system requirements.

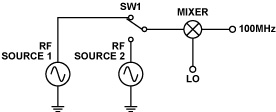

For this application, the RF switch load is a MASW210B-1 silicon PIN diode single-pole double-throw (SPDT) switch used in the front end of a microwave downconverter (Figure 11).

Figure 11. Downconverter functional block diagram

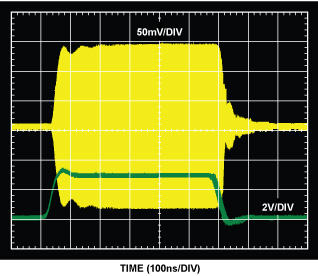

The switch output waveform and TTL input signal are shown in Figure 12. Note that the rising and falling edges are very steep. Since the switching time requirement of the switch is relatively slow (approximately 50 ns), the spike capacitors C5 and C6 are not used in this application. The resistors R11 and R12 that set the steady-state diode current are both 330 Ω.

Figure 12. Waveform showing RF switching speed.

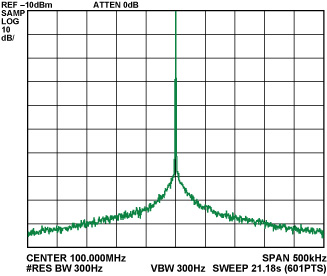

Figure 13. Spectral response of a downconverter.

Figure 13 shows the spectral response of the downconverter front end; switch SW1 is in a fixed position to eliminate insertion loss. Note the absence of harmonics or sidebands, strongly indicating that there are no significant 100 kHz switching artifacts emanating from the ADA4858-3 on-chip charge pump, an important consideration when using these devices in this application.

in conclusion

As shown in the above three examples, op amps can be creatively used as a replacement for traditional amplifiers, with performance comparable to that of dedicated PIN diode driver ICs. In addition, op amps can provide gain adjustment and input control functions, and when using op amps with built-in charge pumps, no negative supply is required, which increases the design flexibility of PIN diode drivers and other circuits. Op amps are easy to use and configure, and can solve complex problems with relative ease.

Previous article:Principle and Application of Zero-Drift Amplifier

Next article:Achieving Precision Absolute Value Output Using a Dual-Channel Difference Amplifier

Recommended ReadingLatest update time:2024-11-17 00:32

- Popular Resources

- Popular amplifiers

-

Modern Electronic Technology Training Course (Edited by Yao Youfeng)

Modern Electronic Technology Training Course (Edited by Yao Youfeng) -

Operational Amplifier Practical Reference Handbook (Edited by Liu Changsheng, Zhao Mingying, Liu Xu, etc.)

Operational Amplifier Practical Reference Handbook (Edited by Liu Changsheng, Zhao Mingying, Liu Xu, etc.) -

A Complete Illustrated Guide to Operational Amplifier Applications (Written by Wang Zhenhong)

A Complete Illustrated Guide to Operational Amplifier Applications (Written by Wang Zhenhong) -

Sensor Principle and Application Circuit Design (Edited by Chen Shuwang, Song Lijun, Xu Yunfeng)

Sensor Principle and Application Circuit Design (Edited by Chen Shuwang, Song Lijun, Xu Yunfeng)

- High signal-to-noise ratio MEMS microphone drives artificial intelligence interaction

- Advantages of using a differential-to-single-ended RF amplifier in a transmit signal chain design

- ON Semiconductor CEO Appears at Munich Electronica Show and Launches Treo Platform

- ON Semiconductor Launches Industry-Leading Analog and Mixed-Signal Platform

- Analog Devices ADAQ7767-1 μModule DAQ Solution for Rapid Development of Precision Data Acquisition Systems Now Available at Mouser

- Domestic high-precision, high-speed ADC chips are on the rise

- Microcontrollers that combine Hi-Fi, intelligence and USB multi-channel features – ushering in a new era of digital audio

- Using capacitive PGA, Naxin Micro launches high-precision multi-channel 24/16-bit Δ-Σ ADC

- Fully Differential Amplifier Provides High Voltage, Low Noise Signals for Precision Data Acquisition Signal Chain

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- If the length of Ethernet data packet exceeds 1500 bytes, does it need to be manually divided into packets?

- [HC32F460 Development Board Review] 06. Simulate I2C to implement OLED display

- Please tell me how to package the bitstream and software core code into one file in Xinlinx ISE

- [RISC-V MCU CH32V103 Review] LED breathing light

- 【Silicon Labs Development Kit Review】– Compilation Environment Installation

- BS EN IEC 62485-5:2021 Safety requirements for secondary cells and battery installations Part 5: Stationary lithium-ion batteries...

- Bear Pie Huawei IoT operating system LiteOS bare metal driver transplantation 04-E53_IA1 expansion board driver and use

- RT1052 (1) Control GPIO output

- Here comes the introduction of outstanding vacuum cleaner design!

- 【MYS-8MMX】- 4: Try Application Finder and Terminal Emulator

Modern Electronic Technology Training Course (Edited by Yao Youfeng)

Modern Electronic Technology Training Course (Edited by Yao Youfeng)

京公网安备 11010802033920号

京公网安备 11010802033920号