0 Introduction

As a universal power supply, the switching power supply is well known for its light, thin, small and high efficiency. It is an indispensable power supply for miniaturization and low cost of various electronic devices and has become the mainstream power supply today. With the rapid development of the electronic information industry, its application scope will inevitably expand day by day, and the demand will also increase day by day.

However, while people enjoy the conveniences brought by the switching power supply, such as light, thin, small and high efficiency, it also brings various hazards of noise interference. In particular, as the switching power supply develops towards smaller size, higher frequency and higher power, the EMI noise brought by its dV/dt and dI/dt will also be greater. Its conducted noise and radiated noise will affect the safety of the whole machine, sometimes interfere with some CPU instructions, cause system misoperation, and in severe cases cause subversive damage to the system. For this reason, when using the switching power supply, we must pay close attention to the hazards caused by the EMI noise of the switching power supply, take active preventive measures to reduce the EMI noise, and minimize the impact of EMI noise.

1 EMI noise current

There are many circuit topologies of switching power supplies. According to the combined working mode of the power switch tube and the high-frequency transformer, they can be divided into full-bridge, half-bridge, push-pull, single-ended forward, single-ended flyback and other modes. In small and medium-power switching power supply modules, the most commonly used circuit topologies are push-pull, single-ended forward, single-ended flyback, etc. The block diagram of a typical single-ended forward switching power supply circuit is shown in Figure 1. It consists of a power switch tube Q1, a high-frequency transformer T, a rectifier diode D1, a freewheeling diode D2, an output filter inductor L, an output filter capacitor C, etc. When working, the PWM control unit can send a pulse signal with a variable pulse width to drive the switch tube Q1. When the switch tube Q1 is turned on, the DC energy at the input end is transmitted to the secondary through the high-frequency transformer. When the switch tube Q1 is turned off, the high-frequency transformer performs magnetic reset. The high-frequency pulse transmitted by the high-frequency transformer is rectified into a single-direction pulsating DC by the rectifier diode. After the pulsating DC is filtered by the output filter inductor and the filter capacitor, the required DC voltage can be sent.

During the high-frequency switching process of the power switch tube Q1, the pulses flowing through the power switch tube and the high-frequency transformer will generate a variety of harmonic voltages and harmonic currents. The noise generated by these harmonic voltages and harmonic currents can be transmitted to the common power supply terminal through the power input line, or transmitted to the load through the output line of the switching power supply, thereby interfering with other systems or sensitive components. The noise spectrum of these noises conducted on the power line is shown in Figure 2. It can be seen from the figure that in the frequency band of several hundred kHz to 50 MHz, that is, in the frequency band of the fundamental wave and several harmonics of the switching frequency, the amplitude of the interference noise far exceeds the range specified by GJBl51A, thus causing the electromagnetic compatibility indicators such as system conduction noise to exceed the standard.

So how are these noises formed and how are they propagated? The following is an analysis of the surface mount switching power supply module with a small and medium power metal package structure as an example.

1.1 Common mode interference current

The entire circuit components of the metal package structure surface mount switching power supply module are all assembled on the substrate. Active devices such as PWM control chips, power switch tubes, rectifier diodes, etc. all use surface mount packaging components. The input and output voltage and current are sent out by the leads, and the schematic diagram of its internal structure is shown in Figure 3.

The bottom plate of the tube shell is the carrier of the alumina substrate. The front of the alumina substrate is the wiring area and the assembly area of the components. The back is metallized with thick film paste and then connected to the metal bottom plate of the tube shell through solder (such as solder, etc.). The dielectric constant of the alumina substrate is 8, and the thickness is usually in the range of 0.5 to 1.0 mm. In the assembly area on the front of the alumina substrate, surface mount components (such as PWM control chips, op amps, reference sources, MOSFET switch tubes, rectifier diodes) are connected to the pads in the wiring area through solder (such as conductive glue, reflow solder, etc.). Although this connection method constitutes a circuit loop, it also brings new parasitic capacitance Cp to the circuit. The distribution of these parasitic capacitances is shown in Figure 4.

In the primary circuit, the power switch chip, PWM control chip, operational amplifier chip, and the traces of the positive and negative input lines of the power supply will generate parasitic capacitance Cp between the bottom plate of the shell. The capacity of the parasitic capacitance depends on the thickness of the substrate and the area they occupy on the bottom plate. In this way, in the circuit, distributed capacitances Cp1, Cp2, ..., Cp6, etc. are formed between these components and their traces and the bottom plate of the shell. These distributed capacitances will cause noise currents under the combined influence of dV/dt, dI/dt, and the reverse recovery current of the rectifier diode. These noise currents are equal in magnitude and phase between the positive and negative input power lines and the positive and negative output load lines, and are called common-mode noise currents. The magnitude of the common-mode noise current is related to the magnitude of the distributed capacitance, dV/dt, dI/dt, etc.

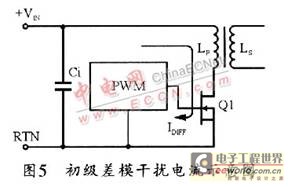

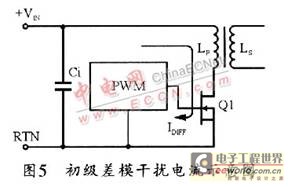

1.2 Primary differential-mode interference current

Figure 5 shows a schematic diagram of the primary differential-mode interference current. In the primary circuit, the power switch tube Q1, the primary winding Lp of the high-frequency transformer and the input filter capacitor Ci constitute the input DC conversion circuit of the switching power supply. When this conversion circuit works normally, it will transfer the input DC energy to the secondary through the high-frequency transformer. However, when the power switch tube Q1 is switched, the fundamental wave and harmonics caused by the rise and fall of the high-frequency pulse will be transmitted to the input power supply end along the input filter capacitor Ci. This noise current propagating along the positive and negative ends of the input power line is called the primary differential mode interference current IDIFF.

This differential mode interference current IDIFF flows to the common power supply end through the input power line. Especially when the input filter capacitor Ci is insufficiently filtered, it will cause great interference to the input power line. It will also interfere with other parts of the system through the common power supply end, thereby reducing the performance indicators of other parts.

1.3 Secondary differential mode interference current

The schematic diagram of the secondary differential mode interference current is shown in Figure 6. In the secondary circuit of the switching power supply, the secondary winding Ls of the high-frequency transformer and the rectifier diode V2 are responsible for transmitting the input energy to the load. The output filter inductor L and the output filter capacitor Co filter the high frequency part. The function of the rectifier diode V2 is to rectify the pulse wave of the secondary winding into direct current. When the pulse wave is at a high level, the rectifier diode is turned on, and energy is transferred to the load at this time. When the pulse wave is at a low level, it is cut off, and the output current is continued through V3. When the rectifier diode V2 changes from on to off, a large reverse recovery current will be generated due to the movement of the carriers of the diode. This reverse recovery current will propagate to the load circuit along the output filter inductor and the output filter capacitor. Therefore, the EMI noise current propagating along the output line contains two parts, one part is the interference current of the switching base frequency and harmonics carried during normal energy transmission, and the other part is the interference current caused by the reverse recovery current of the diode. This noise current propagating along the positive and negative ends of the output line is the differential mode interference current IDIFF.

This differential mode interference current will have a very adverse effect on the load circuit, especially when the output filter capacitor is not filtering enough, it will be particularly severe. It will affect the sensitivity of the analog circuit in the load circuit and the threshold of the digital circuit. In severe cases, it will also cause the circuit to be triggered incorrectly, thereby causing the entire system to work abnormally.

2 EMI noise suppression and filtering

The three elements of electromagnetic interference are interference source, interference path and interference object. To completely solve the electromagnetic interference problem, in essence, the interference source should be reduced. Only when the amplitude of the interference source is reduced can the electromagnetic interference be fundamentally suppressed. To reduce the EMI interference amplitude of the switching power supply, it is necessary to reduce dV/dt and dI/dt, that is, reduce the switching speed. However, this method will reduce the conversion efficiency of the switching power supply. Therefore, for this solution, various factors must be considered comprehensively before it can be adopted.

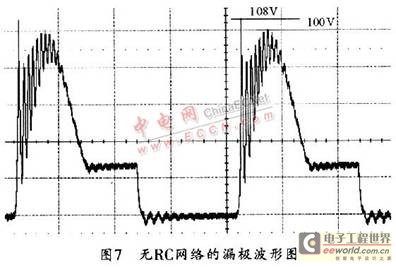

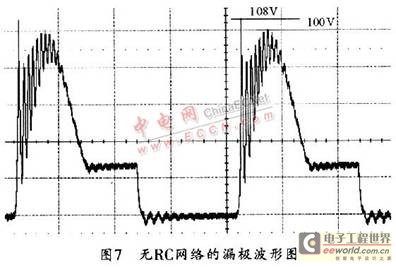

2.1 RC absorption of the primary coil of the high-frequency transformer

The input voltage of the single-ended forward switching power supply is 28 V. When the power switch tube and the high-frequency converter are working, the waveform on the drain of the power switch tube Ql is shown in Figure 7. When the power switch tube Q1 changes from on to off, the high-frequency transformer performs resonance reset, and its resonance peak is 100 V at this time. The noise peak can reach 108 V instantaneously. Such a high peak voltage is transmitted along the power input line, which will cause strong conduction interference and radiation interference.

In order to reduce the peak voltage, an RC absorption network can be connected in parallel to the primary coil loop of the high-frequency transformer. Figure 8 shows the drain waveform of the power switch tube Ql after the parallel RC circuit. In the figure, its resonance peak is 60 V and the noise peak is only 66 V. It can be seen that the parallel RC absorption network can effectively reduce the resonance peak, thereby greatly reducing the EMI interference to the power supply end.

2.2 Installing EMI filter

Installing EMI power filter is one of the best ways to suppress EMI noise. Installing an EMI power filter at the power input end can achieve a dual effect. It can not only suppress the EMI interference generated by the switching power supply from being transmitted to the power supply end, but also suppress the interference caused by the EMI noise from the power supply end to the switching power supply.

The circuit structure of the EMI power filter is shown in Figure 9. The circuit consists of a common-mode filter circuit and a differential-mode filter circuit. Among them, L1 and L2 are two independent coils wound on the same magnetic core, called common-mode coils, with the same number of turns and opposite winding directions. In this way. After the EMI filter is connected to the circuit, the magnetic flux generated by the differential-mode current in the two coils will cancel each other in the magnetic tank, so that the magnetic tank will not reach magnetic saturation, so the inductance values of the two coils can remain unchanged. Among them, L1 and CY1, L2 and CY2 respectively constitute low-pass filters between the two independent ports of LE and NE, which can suppress the common-mode EMI signals on the power line so that these common-mode EMI signals cannot be conducted on the power line. L3 and CX constitute a low-pass filter between the independent ports of LN, which can be used to suppress the differential-mode EMI signals on the power line. Combining these two aspects, it is possible to suppress the common-mode EMI signals and differential-mode EMI signals on the power line.

The common mode inductance Ll and L2 are generally from a few mH to tens of mH. The common mode capacitance Cy should be as large as possible under the condition of meeting the circuit requirements in order to obtain better filtering effect. The differential mode inductance is generally from tens of μH to hundreds of μH. The differential mode capacitance Cx should be a ceramic capacitor with a sufficiently high withstand voltage. The magnetic material of the common mode inductor is better with high magnetic permeability soft magnetic material, and the magnetic material of the differential mode inductor is better with metal iron powder core with high saturation flux density. It is best not to use open ferrite material.

After installing the EMI power filter, the noise spectrum on the power line is shown in Figure 10. Compared with Figure 2, the suppression of EMI noise by the installation of EMI filter is very obvious. In all frequency bands, the noise is suppressed and all meet the military standard requirements.

2.3 Installation of EMI power filter

When installing EMI power filter, you must pay attention to the correct installation method. The wrong installation method not only fails to suppress noise, but sometimes has the opposite effect. According to the characteristics of EMI filter and switching power supply, when installing EMI filter, you should pay attention to two aspects. First, the shell of the EMI power filter must be grounded and must be connected to the shell of the switching power supply. This is because the common-mode filter capacitors of the EMI power filter are connected to the shell of the product. Only when the shell of the EMI power filter is connected to the housing, the common-mode filter circuit of the filter will work, so that the common-mode interference current generated by the switching power supply can be filtered out. In addition, a thicker wire should be used to connect the filter shell to the housing. At the same time, the lower the grounding impedance, the better the filtering effect. Second, the EMI power filter must be installed at the entrance of the power supply, and the input and output ends of the filter should be as far away as possible. At the same time, the input and output lines should not bypass the filter to generate cross interference.

3 EMI noise standards

The limit standards for EMI noise include FCC-Paxt-15 in the United States, VDE-087l in Germany, CISPR-Pub22 in IEC, etc. The military standards include MIL-STD-461 in the United States, and GJBl5lA in China. These standards all specify the conduction limits of EMI noise of different frequency bands in the system or the whole machine on the power input line. At the same time, each standard also stipulates the frequency range of the conducted noise that should be measured, as shown in Table 1. The corresponding test standards include CISPR-Publ7, GJBl52A, etc.

The test of electromagnetic capacitance mainly includes two major items: conduction and radiation, and conduction and radiation include two items: emission and sensitivity. Therefore, it is expanded to four sub-items: conducted emission, conducted sensitivity, radiated emission, and radiated sensitivity. The measurement items for switching power supplies specified in GJBl51A-97 are listed in Table 2.

4 Conclusion

How to make the whole machine pass the electromagnetic compatibility test is a matter of increasing concern to system designers. To solve the electromagnetic compatibility problem comprehensively and systematically, it is necessary to start from the initial design and the most basic principles. Studies have shown that electromagnetic compatibility design must be considered from the early stage of system development (i.e., the scheme demonstration stage) and should run through all stages of the development process. Moreover, electromagnetic compatibility design is the key link to achieve system electromagnetic compatibility. Data shows that if electromagnetic compatibility design is carried out when the product is first developed, about 90% of the conducted and radiated interference can be controlled. It can be seen that starting from the analysis of the generation of EMI noise, finding ways to suppress EMI noise, and knowing the relevant EMI noise testing methods will be of great benefit to the whole machine passing the electromagnetic compatibility test.

Keywords:EMI

Reference address:EMI Noise Analysis and EMI Filter Design

As a universal power supply, the switching power supply is well known for its light, thin, small and high efficiency. It is an indispensable power supply for miniaturization and low cost of various electronic devices and has become the mainstream power supply today. With the rapid development of the electronic information industry, its application scope will inevitably expand day by day, and the demand will also increase day by day.

However, while people enjoy the conveniences brought by the switching power supply, such as light, thin, small and high efficiency, it also brings various hazards of noise interference. In particular, as the switching power supply develops towards smaller size, higher frequency and higher power, the EMI noise brought by its dV/dt and dI/dt will also be greater. Its conducted noise and radiated noise will affect the safety of the whole machine, sometimes interfere with some CPU instructions, cause system misoperation, and in severe cases cause subversive damage to the system. For this reason, when using the switching power supply, we must pay close attention to the hazards caused by the EMI noise of the switching power supply, take active preventive measures to reduce the EMI noise, and minimize the impact of EMI noise.

1 EMI noise current

There are many circuit topologies of switching power supplies. According to the combined working mode of the power switch tube and the high-frequency transformer, they can be divided into full-bridge, half-bridge, push-pull, single-ended forward, single-ended flyback and other modes. In small and medium-power switching power supply modules, the most commonly used circuit topologies are push-pull, single-ended forward, single-ended flyback, etc. The block diagram of a typical single-ended forward switching power supply circuit is shown in Figure 1. It consists of a power switch tube Q1, a high-frequency transformer T, a rectifier diode D1, a freewheeling diode D2, an output filter inductor L, an output filter capacitor C, etc. When working, the PWM control unit can send a pulse signal with a variable pulse width to drive the switch tube Q1. When the switch tube Q1 is turned on, the DC energy at the input end is transmitted to the secondary through the high-frequency transformer. When the switch tube Q1 is turned off, the high-frequency transformer performs magnetic reset. The high-frequency pulse transmitted by the high-frequency transformer is rectified into a single-direction pulsating DC by the rectifier diode. After the pulsating DC is filtered by the output filter inductor and the filter capacitor, the required DC voltage can be sent.

During the high-frequency switching process of the power switch tube Q1, the pulses flowing through the power switch tube and the high-frequency transformer will generate a variety of harmonic voltages and harmonic currents. The noise generated by these harmonic voltages and harmonic currents can be transmitted to the common power supply terminal through the power input line, or transmitted to the load through the output line of the switching power supply, thereby interfering with other systems or sensitive components. The noise spectrum of these noises conducted on the power line is shown in Figure 2. It can be seen from the figure that in the frequency band of several hundred kHz to 50 MHz, that is, in the frequency band of the fundamental wave and several harmonics of the switching frequency, the amplitude of the interference noise far exceeds the range specified by GJBl51A, thus causing the electromagnetic compatibility indicators such as system conduction noise to exceed the standard.

So how are these noises formed and how are they propagated? The following is an analysis of the surface mount switching power supply module with a small and medium power metal package structure as an example.

1.1 Common mode interference current

The entire circuit components of the metal package structure surface mount switching power supply module are all assembled on the substrate. Active devices such as PWM control chips, power switch tubes, rectifier diodes, etc. all use surface mount packaging components. The input and output voltage and current are sent out by the leads, and the schematic diagram of its internal structure is shown in Figure 3.

The bottom plate of the tube shell is the carrier of the alumina substrate. The front of the alumina substrate is the wiring area and the assembly area of the components. The back is metallized with thick film paste and then connected to the metal bottom plate of the tube shell through solder (such as solder, etc.). The dielectric constant of the alumina substrate is 8, and the thickness is usually in the range of 0.5 to 1.0 mm. In the assembly area on the front of the alumina substrate, surface mount components (such as PWM control chips, op amps, reference sources, MOSFET switch tubes, rectifier diodes) are connected to the pads in the wiring area through solder (such as conductive glue, reflow solder, etc.). Although this connection method constitutes a circuit loop, it also brings new parasitic capacitance Cp to the circuit. The distribution of these parasitic capacitances is shown in Figure 4.

In the primary circuit, the power switch chip, PWM control chip, operational amplifier chip, and the traces of the positive and negative input lines of the power supply will generate parasitic capacitance Cp between the bottom plate of the shell. The capacity of the parasitic capacitance depends on the thickness of the substrate and the area they occupy on the bottom plate. In this way, in the circuit, distributed capacitances Cp1, Cp2, ..., Cp6, etc. are formed between these components and their traces and the bottom plate of the shell. These distributed capacitances will cause noise currents under the combined influence of dV/dt, dI/dt, and the reverse recovery current of the rectifier diode. These noise currents are equal in magnitude and phase between the positive and negative input power lines and the positive and negative output load lines, and are called common-mode noise currents. The magnitude of the common-mode noise current is related to the magnitude of the distributed capacitance, dV/dt, dI/dt, etc.

1.2 Primary differential-mode interference current

Figure 5 shows a schematic diagram of the primary differential-mode interference current. In the primary circuit, the power switch tube Q1, the primary winding Lp of the high-frequency transformer and the input filter capacitor Ci constitute the input DC conversion circuit of the switching power supply. When this conversion circuit works normally, it will transfer the input DC energy to the secondary through the high-frequency transformer. However, when the power switch tube Q1 is switched, the fundamental wave and harmonics caused by the rise and fall of the high-frequency pulse will be transmitted to the input power supply end along the input filter capacitor Ci. This noise current propagating along the positive and negative ends of the input power line is called the primary differential mode interference current IDIFF.

This differential mode interference current IDIFF flows to the common power supply end through the input power line. Especially when the input filter capacitor Ci is insufficiently filtered, it will cause great interference to the input power line. It will also interfere with other parts of the system through the common power supply end, thereby reducing the performance indicators of other parts.

1.3 Secondary differential mode interference current

The schematic diagram of the secondary differential mode interference current is shown in Figure 6. In the secondary circuit of the switching power supply, the secondary winding Ls of the high-frequency transformer and the rectifier diode V2 are responsible for transmitting the input energy to the load. The output filter inductor L and the output filter capacitor Co filter the high frequency part. The function of the rectifier diode V2 is to rectify the pulse wave of the secondary winding into direct current. When the pulse wave is at a high level, the rectifier diode is turned on, and energy is transferred to the load at this time. When the pulse wave is at a low level, it is cut off, and the output current is continued through V3. When the rectifier diode V2 changes from on to off, a large reverse recovery current will be generated due to the movement of the carriers of the diode. This reverse recovery current will propagate to the load circuit along the output filter inductor and the output filter capacitor. Therefore, the EMI noise current propagating along the output line contains two parts, one part is the interference current of the switching base frequency and harmonics carried during normal energy transmission, and the other part is the interference current caused by the reverse recovery current of the diode. This noise current propagating along the positive and negative ends of the output line is the differential mode interference current IDIFF.

This differential mode interference current will have a very adverse effect on the load circuit, especially when the output filter capacitor is not filtering enough, it will be particularly severe. It will affect the sensitivity of the analog circuit in the load circuit and the threshold of the digital circuit. In severe cases, it will also cause the circuit to be triggered incorrectly, thereby causing the entire system to work abnormally.

2 EMI noise suppression and filtering

The three elements of electromagnetic interference are interference source, interference path and interference object. To completely solve the electromagnetic interference problem, in essence, the interference source should be reduced. Only when the amplitude of the interference source is reduced can the electromagnetic interference be fundamentally suppressed. To reduce the EMI interference amplitude of the switching power supply, it is necessary to reduce dV/dt and dI/dt, that is, reduce the switching speed. However, this method will reduce the conversion efficiency of the switching power supply. Therefore, for this solution, various factors must be considered comprehensively before it can be adopted.

2.1 RC absorption of the primary coil of the high-frequency transformer

The input voltage of the single-ended forward switching power supply is 28 V. When the power switch tube and the high-frequency converter are working, the waveform on the drain of the power switch tube Ql is shown in Figure 7. When the power switch tube Q1 changes from on to off, the high-frequency transformer performs resonance reset, and its resonance peak is 100 V at this time. The noise peak can reach 108 V instantaneously. Such a high peak voltage is transmitted along the power input line, which will cause strong conduction interference and radiation interference.

In order to reduce the peak voltage, an RC absorption network can be connected in parallel to the primary coil loop of the high-frequency transformer. Figure 8 shows the drain waveform of the power switch tube Ql after the parallel RC circuit. In the figure, its resonance peak is 60 V and the noise peak is only 66 V. It can be seen that the parallel RC absorption network can effectively reduce the resonance peak, thereby greatly reducing the EMI interference to the power supply end.

2.2 Installing EMI filter

Installing EMI power filter is one of the best ways to suppress EMI noise. Installing an EMI power filter at the power input end can achieve a dual effect. It can not only suppress the EMI interference generated by the switching power supply from being transmitted to the power supply end, but also suppress the interference caused by the EMI noise from the power supply end to the switching power supply.

The circuit structure of the EMI power filter is shown in Figure 9. The circuit consists of a common-mode filter circuit and a differential-mode filter circuit. Among them, L1 and L2 are two independent coils wound on the same magnetic core, called common-mode coils, with the same number of turns and opposite winding directions. In this way. After the EMI filter is connected to the circuit, the magnetic flux generated by the differential-mode current in the two coils will cancel each other in the magnetic tank, so that the magnetic tank will not reach magnetic saturation, so the inductance values of the two coils can remain unchanged. Among them, L1 and CY1, L2 and CY2 respectively constitute low-pass filters between the two independent ports of LE and NE, which can suppress the common-mode EMI signals on the power line so that these common-mode EMI signals cannot be conducted on the power line. L3 and CX constitute a low-pass filter between the independent ports of LN, which can be used to suppress the differential-mode EMI signals on the power line. Combining these two aspects, it is possible to suppress the common-mode EMI signals and differential-mode EMI signals on the power line.

The common mode inductance Ll and L2 are generally from a few mH to tens of mH. The common mode capacitance Cy should be as large as possible under the condition of meeting the circuit requirements in order to obtain better filtering effect. The differential mode inductance is generally from tens of μH to hundreds of μH. The differential mode capacitance Cx should be a ceramic capacitor with a sufficiently high withstand voltage. The magnetic material of the common mode inductor is better with high magnetic permeability soft magnetic material, and the magnetic material of the differential mode inductor is better with metal iron powder core with high saturation flux density. It is best not to use open ferrite material.

After installing the EMI power filter, the noise spectrum on the power line is shown in Figure 10. Compared with Figure 2, the suppression of EMI noise by the installation of EMI filter is very obvious. In all frequency bands, the noise is suppressed and all meet the military standard requirements.

2.3 Installation of EMI power filter

When installing EMI power filter, you must pay attention to the correct installation method. The wrong installation method not only fails to suppress noise, but sometimes has the opposite effect. According to the characteristics of EMI filter and switching power supply, when installing EMI filter, you should pay attention to two aspects. First, the shell of the EMI power filter must be grounded and must be connected to the shell of the switching power supply. This is because the common-mode filter capacitors of the EMI power filter are connected to the shell of the product. Only when the shell of the EMI power filter is connected to the housing, the common-mode filter circuit of the filter will work, so that the common-mode interference current generated by the switching power supply can be filtered out. In addition, a thicker wire should be used to connect the filter shell to the housing. At the same time, the lower the grounding impedance, the better the filtering effect. Second, the EMI power filter must be installed at the entrance of the power supply, and the input and output ends of the filter should be as far away as possible. At the same time, the input and output lines should not bypass the filter to generate cross interference.

3 EMI noise standards

The limit standards for EMI noise include FCC-Paxt-15 in the United States, VDE-087l in Germany, CISPR-Pub22 in IEC, etc. The military standards include MIL-STD-461 in the United States, and GJBl5lA in China. These standards all specify the conduction limits of EMI noise of different frequency bands in the system or the whole machine on the power input line. At the same time, each standard also stipulates the frequency range of the conducted noise that should be measured, as shown in Table 1. The corresponding test standards include CISPR-Publ7, GJBl52A, etc.

The test of electromagnetic capacitance mainly includes two major items: conduction and radiation, and conduction and radiation include two items: emission and sensitivity. Therefore, it is expanded to four sub-items: conducted emission, conducted sensitivity, radiated emission, and radiated sensitivity. The measurement items for switching power supplies specified in GJBl51A-97 are listed in Table 2.

4 Conclusion

How to make the whole machine pass the electromagnetic compatibility test is a matter of increasing concern to system designers. To solve the electromagnetic compatibility problem comprehensively and systematically, it is necessary to start from the initial design and the most basic principles. Studies have shown that electromagnetic compatibility design must be considered from the early stage of system development (i.e., the scheme demonstration stage) and should run through all stages of the development process. Moreover, electromagnetic compatibility design is the key link to achieve system electromagnetic compatibility. Data shows that if electromagnetic compatibility design is carried out when the product is first developed, about 90% of the conducted and radiated interference can be controlled. It can be seen that starting from the analysis of the generation of EMI noise, finding ways to suppress EMI noise, and knowing the relevant EMI noise testing methods will be of great benefit to the whole machine passing the electromagnetic compatibility test.

Previous article:DS8500 HART Modem

Next article:Measurement Techniques for Integrated Circuit RF Noise Suppression Capability

Recommended ReadingLatest update time:2024-11-16 16:43

Mouser Now Stocking Vishay VEMI256A-SD2 EMI Filters

Ideal for small mobile and wired communication devices where space is limited February 7, 2022 – Mouser Electronics, the industry’s leading New Product Introduction (NPI) distributor of the broadest selection of semiconductors and electronic components™ Mouser Electronics is now stocking Vishay Intertechnology'

[Power Management]

Engineer: EMI solution based on multi-layer PCB design

Power Bus Placing capacitors of appropriate capacity near the power pins of the IC can make the IC output voltage jump faster. However, the problem does not end there. Due to the limited frequency response characteristics of the capacitor, it is impossible for the capacitor to generate the harmonic power required to

[Power Management]

Anti-electromagnetic interference EMI and ESD protection technology in mobile phone design

Currently, for many popular mobile phones (especially flip phones), the color LCD, OLED display or camera module CMOS sensor and other components of the mobile phone are connected to the baseband controller through flexible circuits or long-line PCBs. These connecting lines will be interfered by the parasitic GSM/CDMA

[Power Management]

Analysis of EMI radiation signal strength

How far away from the radiation source should the radiation signal not interfere with the system? To know the answer to this question, you need to consider the following two questions: 1) the radiation energy of the radiation source; 2) the performance of the system's EMI protection circuit. In this article, we will

[Power Management]

Practical application of integrated amplifier power IC to reduce EMI interference technology

In a flip phone, if the audio amplifier and RF receiver are both on the body, the RF receiver will affect the EMI of the audio amplifier. If the audio amplifier is moved to the flip cover, EMI can be reduced and there is no need to use a low-frequency filter. Since the speaker is also on the flip cover, the length of

[Power Management]

How to improve EMC & EMI of electronic products

How to improve EMC & EMI of electronic products

When developing electronic products with processors, how to improve anti-interference ability and electromagnetic compatibility?

1. The following systems should pay special attention to anti-electromagnetic interference:

(1) Systems with very high microc

[Microcontroller]

How to choose EN55022 standard low EMI power supply

introduction As the market demands for improved performance of information technology and communication equipment, today's system designers are faced with the challenge of having to design EMI compliant products. Before being sold, all information technology equipment (ITE), which is usually specified as having a

[Power Management]

Low noise DC/DC module regulator meets EMI and SERDES regulations

Ultra-low noise DC/DC micromodule (uModuleTM) regulators LTM4606 and LTM4612, these two devices provide low noise power by attenuating radiated energy and conducting broadband harmonic energy. Designed for regulating outputs from 0.6V to up to 5V, the LTM4606 has been verified by Xilinx and has achieved flawles

[Power Management]

- Popular Resources

- Popular amplifiers

-

Study on the Behavioral Model of Silicon Carbide MOSFET Power Module and EMI Prediction of Low-Voltage Auxiliary Power Supply

Study on the Behavioral Model of Silicon Carbide MOSFET Power Module and EMI Prediction of Low-Voltage Auxiliary Power Supply -

Cable radiated EMI modeling considering mutual coupling effects_Junpeng Ji

Cable radiated EMI modeling considering mutual coupling effects_Junpeng Ji -

Design of broadband hybrid active EMI filter for switching power supply_Liao Yuehong

Design of broadband hybrid active EMI filter for switching power supply_Liao Yuehong -

Switching power supply conducted EMI simulation and filter circuit design_Jiang Yunfu

Switching power supply conducted EMI simulation and filter circuit design_Jiang Yunfu

Recommended Content

Latest Analog Electronics Articles

- High signal-to-noise ratio MEMS microphone drives artificial intelligence interaction

- Advantages of using a differential-to-single-ended RF amplifier in a transmit signal chain design

- ON Semiconductor CEO Appears at Munich Electronica Show and Launches Treo Platform

- ON Semiconductor Launches Industry-Leading Analog and Mixed-Signal Platform

- Analog Devices ADAQ7767-1 μModule DAQ Solution for Rapid Development of Precision Data Acquisition Systems Now Available at Mouser

- Domestic high-precision, high-speed ADC chips are on the rise

- Microcontrollers that combine Hi-Fi, intelligence and USB multi-channel features – ushering in a new era of digital audio

- Using capacitive PGA, Naxin Micro launches high-precision multi-channel 24/16-bit Δ-Σ ADC

- Fully Differential Amplifier Provides High Voltage, Low Noise Signals for Precision Data Acquisition Signal Chain

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

Study on the Behavioral Model of Silicon Carbide MOSFET Power Module and EMI Prediction of Low-Voltage Auxiliary Power Supply

Study on the Behavioral Model of Silicon Carbide MOSFET Power Module and EMI Prediction of Low-Voltage Auxiliary Power Supply

京公网安备 11010802033920号

京公网安备 11010802033920号