introduction

At present, most of the common wireless remote controls on the market are four-key and twelve-key, mainly used in car anti-theft systems, home anti-theft systems and remote control toys. These applications are simple, practical and low-cost. However, for some projects that require a distance of more than 100 meters, control or set some data, and require a remote control for more than 12 or even hundreds of devices, the above remote controls are inconvenient for operators, and the system performance is not stable enough. In view of the above situation, we proposed to use a single-chip microcomputer to write the address on this basis, set it through the operation key, and display the output of the remote control on the LCD. At the same time, a new type of intelligent remote control was designed and developed for the requirements of power consumption, multiple control settings, easy to carry, easy to operate and stable performance. This type of remote control uses TI's ultra-low power single-chip microcomputer MSP430F413 as the microprocessor, equipped with a low-power 3-digit LCD display EDS812A, the entire system uses lithium batteries and high-energy silver oxide batteries as power supply, and has the characteristics of low power consumption, small size, light weight, easy programming and long service life. The circuit principle block diagram of the remote control is shown in Figure 1, which consists of power supply circuit, LCD display, button control, address output, transmitting module and other circuits.

MCU interface

Considering the requirements of low power consumption, small size, LCD display, key addressing, etc., the MSP430F413 single-chip microcomputer chip is selected. It has obvious advantages over other single-chip microcomputers in online system design, development and debugging, and practical application. The schematic diagram of the single-chip microcomputer interface circuit is shown in Figure 2.

Power Circuit

The power supply circuit of this system consists of two independent power supplies, which do not interfere with each other. The reason for using two independent power supply systems is mainly based on the following considerations: 1. In actual use, it is found that the single-chip microcomputer will interfere with the receiving circuit when working, affecting the control function; 2. The transmission current varies with the remote control distance. The longer the distance, the greater the current, which directly affects the operation of the single-chip microcomputer; 3. The optimal operating voltage of the transmitter module is about 12V, while the operating voltage of the single-chip microcomputer system is 1.8-3.6V. In this way, a general DC-DC step-down chip must be used, which will increase the cost. In addition, the transmitter module and the single-chip microcomputer system share the same ground, and the interference between them cannot be completely eliminated. In view of the above factors, from the perspective of actual use, lithium batteries and high-energy silver oxide batteries are used for independent power supply. [page]

The single-chip microcomputer system is powered by a lithium battery CR2032 (capacity 210mAh, voltage 3.0V). The remote control part is powered by two high-energy silver oxide batteries 476A (capacity 165mAh, voltage 6.0V) connected in series. The current of the entire system is less than 1 mA when working and less than 3mA when not working. When the single-chip microcomputer part is keyless, the power switch can be turned off or the system will automatically enter low power consumption mode after 20 minutes, which can save energy; the power supply of the remote control part does not consume power when it is keyless. Therefore, the power circuit design of the system can achieve the indicators of low power consumption, economical and practical, and stable and reliable performance.

Button control part

The remote control has 6 buttons: 2 setting buttons (KEY1, KEY2) and 4 function buttons (S1-S4), which together complete specific functional operations. Due to the low power design requirements, the system power consumption is reduced as much as possible when a key is pressed, so the address output part and the LCD display part are completed with a combination key, that is, after the LCD setting is completed, press the confirmation button KEY2 to output the address. At this time, pressing the function key will have the remote control function, otherwise it cannot be remotely controlled. At the same time, scan the button operation. If no key is pressed for about 20 minutes, the MSP430 microcontroller will enter the low power mode; if any key is pressed, the address will be set again and output.

LCD display module

The LCD display uses the standard segment low-power 3-bit LCD EDS812A, which has 23 segment outputs and 1 common output. The MSP430F413 microcontroller has its own LCD driver LCD96 segments to complete the display interface of the system, so the static drive method is used for direct wiring, which is simple, reliable and easy to program. The R30 pin of the MSP430F413 must be grounded.

Address output unit

The unit consists of two high-transmission-ratio optocouplers TLP627-4 and their corresponding chip resistors. Since the operating voltage of the transmission control part is in the range of 4~15V, the address output of the microcontroller system and the remote control transmission control part have different operating voltages, so photoelectric isolation and level conversion are used to make the control and setting parts work accurately and reliably. Chip resistors are widely used in various electronic components.

Remote control module

PT2262 and PT2272 are a pair of encoding and decoding chips. The oscillation frequency is adjusted by an external chip resistor. The encoding signal sent by the encoding chip PT2262 is composed of an address code, data code, and synchronization code to form a complete code word. After the decoding chip PT2272 receives the signal, its address code is compared and checked twice, and the VT pin outputs a high level. At the same time, the corresponding data pin also outputs a high level. If the transmitter keeps pressing the button, the encoding chip will also transmit continuously. When no key is pressed in the transmitter module, PT2262 is not powered on, and its 17th pin is low, so the 315MHz high-frequency transmitter circuit does not work; when a key is pressed, PT2262 is powered on, and its 17th pin outputs a modulated serial data signal. When the 17th pin is high, the 315MHz high-frequency transmitter circuit starts to oscillate and transmits a constant-amplitude high-frequency signal; when the 17th pin is low, the 315MHz high-frequency transmitter circuit stops oscillating, so the high-frequency transmitter circuit is completely controlled by the digital signal output by the 17th pin of PT2262, thereby completing the amplitude keying (ASK modulation) of the high-frequency circuit, which is equivalent to an amplitude modulation of 100%. The 1st to 8th pins of the encoding chip PT2262 and the decoding chip PT2272 are address settings, and you can choose to be suspended, connected to the positive power supply, and grounded. The address code is non-repetitive for 6561 groups. Only when the address codes of PT2262 and PT2272 are exactly the same can they be paired. For ease of management, the manufacturer leaves all eight address coding ends of PT2262 and PT2272 floating when they leave the factory. If the user wants to change the address coding, just set pins 1 to 8 of PT2262 and PT2272 to be the same.

The intelligent remote control uses the high and low levels output by the P6 port of MSP430F413, which is connected to the address setting pin of PT2262 through an optocoupler. The address is programmed by the single-chip microcomputer. Each setting has a unique address output. The corresponding PT2272 address setting pin should also be set to the corresponding high and low levels. At this time, when the function key of the remote control is operated, the device containing this PT2272 will have corresponding actions, while other devices containing PT2272 will not act. In this way, accurate and reliable functions are guaranteed.

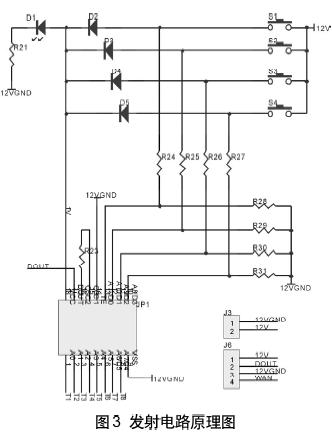

Wireless transmitter unit

This module is based on the encoding chip PT2262, which is connected to the transmitter module 9912 and can remotely control the distance of more than 100 meters. There is also a SC2262 chip that is fully compatible with PT2262. The peripheral circuit does not need to be modified. The encoding and decoding circuit is simple and has few external components. There can be up to 12 bits (A0-A11) of three-state address pins (suspended, connected to high level, connected to low level) to provide 531441 address codes. This design uses 8-bit address setting pins (A0-A8), and chooses to connect to the positive power supply and ground. The combination can provide 256 address codes. PT2262 uses 4-bit (D0-D3) data pins. The set address code and data code are serially output from pin 17, which can be used for wireless remote control transmission circuits. The schematic diagram of the transmitting circuit is shown in Figure 3.

Wireless receiving unit

This module is a receiving module SB-JS1 with the decoding chip PT2272 as the core. The receiving module has seven leads, namely VCC, GND, D1, D2, D3, D4 and VT. Among them, the VT end is the effective output end of the decoding, and D1~D4 are the four-bit data latch output ends, which can output a high level of about 4V and a driving current of 2mA, corresponding to the four keys S1, S2, S3, and S4 on the transmitter. The receiving module is manufactured using SMD patch technology and is a super-regenerative receiving method. It contains amplification shaping and decoding circuits and is extremely convenient to use. [page]

Software Design

The development and debugging tool for this system software design is the embedded workbench EW430, which provides a complete development environment. In terms of supporting TI FET drivers, the function of EW430 is unique, and the latest version is 1.26B. This development tool supports multiple operating systems such as Windows 98/ME/NT4/2000/XP. In this development environment, you can create project files, edit files, compile, assemble, link, create target files, and debug target files.

MSP430 IAR C-SPY debugger is a fast and cost-effective tool developed for testing logic programs and simulations. It can download the program completely to the IDE. In IAR Embedded Workbench, you can easily enter the C-SPY debugging environment. The editing function is like a source code browser, which allows the program to be edited and debugged at the same time. Breakpoints can be set directly in the code, register windows, memory windows, observation windows, etc., which can be very convenient to debug the user-designed program. Hardware debugging is mainly connected to the target board through TI's JTAG Flash emulation tool MSP-FET430. Assembly language and C language source files can be edited and debugged at the same time.

The IAR C language of the MSP430 series is highly compatible with the standard C language, and all the documentation is easy to understand and easy to transplant. The entire program is designed in C language, with a modular structure, clear organization, and a concise program volume, which optimizes the speed and compiler capacity of the MSP430.

Conclusion

This design uses MSP430F413 microcontroller, and its rich on-chip peripheral function modules greatly simplify the peripheral circuits. Most components are packaged in SMD form, which reduces the entire board area. At the same time, a variety of energy-saving working modes are used in software design, so that the power consumption of the entire system is very low and can meet the battery power supply requirements. At present, it has been well verified in practical applications, with high precision, accurate control, and strong anti-interference.

Previous article:MSP430 DMA controller features and module functions

Next article:Design of intelligent LED street light controller based on STC microcontroller

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- LCD Operation (S3C2440)

- The operational amplifier forms a three-point capacitor oscillation

- [NXP Rapid IoT Review] First give SLN-RPK-NODE an emulator

- Guangdong companies are looking for electronic engineers/structural engineers/acoustic engineers

- Can the output voltage of an LDO be equal to the input voltage?

- After importing the 2812 project example, it prompts that it does not match and cannot be run

- EFT 2B, but all others passed.

- STM32 freezes and needs power-on reset

- Schematic diagram and PCB of EBAZ4205 mining board based on Z7010

- 【Repost】Analysis of the process and principle of lithium battery core slurry

Chip Manufacturing: A Practical Tutorial on Semiconductor Process Technology (Sixth Edition)

Chip Manufacturing: A Practical Tutorial on Semiconductor Process Technology (Sixth Edition) MSP430F413---RFT5557 card reader and writer program

MSP430F413---RFT5557 card reader and writer program Selection of Microcontroller Application Technology 10

Selection of Microcontroller Application Technology 10

京公网安备 11010802033920号

京公网安备 11010802033920号