Introduction

Controller Area Network (CAN) is a bus-type serial communication network designed by Bosch of Germany for automobile monitoring systems. It has good networking flexibility, openness, scalability and compatibility. It has strong anti-interference, self-diagnosis, self-monitoring and error correction capabilities, high reliability, simple protocol model structure, good real-time performance, high cost performance and easy development. It is currently the only field bus with international standards. Its application range has far exceeded automobile monitoring systems. It is suitable for distributed automatic control systems in many fields, such as industrial process control and automation, intelligent structure and distributed management, etc., and has become a field bus with great potential for popularization and application.

In order to facilitate the popularization and application of CAN bus in different fields, a simulation platform of the basic component unit of CAN bus system, the node, is developed. Through simulation, the cost and cycle of research and development of CAN bus system are reduced, which is of great practical application value.

This simulation platform uses Philips' SJA1000 chip as the CAN controller. In addition to all the functions of the basic CANPCA82C200 chip standard mode, it also adds a new working mode - PeliCAN mode. This mode supports the CAN2.0B protocol with many new features, such as: stronger compatibility and scalability, stronger error detection and correction capabilities, support for hot plugging, etc. The design is more convenient and flexible, and the chip is low-priced, which is very suitable for use as a general CAN bus system node simulation platform.

In order to meet the needs of automatic control system simulation in various different fields, ordinary PCs can be used as simulators for sensors, actuators, and human-machine keying and display interfaces of various automatic control systems to form a simulation platform and improve the versatility, flexibility and scalability of the nodes. Various application systems can be simulated by simulating PCs.

Hardware design of simulation platform

The hardware system block diagram of the designed CAN bus system node simulation platform is shown in Figure 1.

Figure 1 CAN bus system node simulation platform

The bus system uses low-cost and easy-to-install twisted pair as the communication medium to connect each node into a network system. Each node consists of four functional modules: CAN controller, CAN transceiver, microprocessor and emulated PC.

CAN controller SJA1000 is the core and executes CAN protocol, including data framing and deframing, frame transmission and reception, etc.

Due to the limited bus driving capability of SJA1000, it is connected to the physical bus through CAN transceiver PCA82C250 chip. CAN transceiver converts the logic level signal from CAN controller into a logic level signal suitable for transmission on CAN bus and can be received by CAN transceiver, which plays the role of resisting instantaneous interference and radio frequency interference, increasing communication distance and protecting bus. In order to further enhance the anti-interference capability, high-speed photocoupler 6N137 can be used between SJA1000 and PCA82C250 to realize the level isolation between CAN nodes on the bus.

CAN controller and transceiver cooperate to complete the communication protocol functions of physical layer and data link layer in CAN protocol. Microprocessor 89C51 controls the functions of SJA1000, including initialization and monitoring management, realizes data transmission and reception communication, and executes application layer functions.

The simulation PC realizes level conversion and communication with the microprocessor through the serial port chip MAX232, thereby realizing communication with the CAN bus. The PC can be used as a simulator for sensors, actuators, and human-machine keying and display interfaces of various automatic control systems to form a simulation platform to improve the versatility, flexibility and scalability of the nodes. Various application systems can be simulated by simulating the PC.

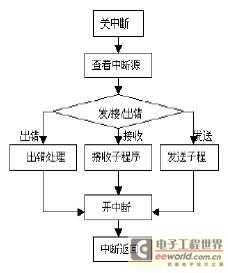

Software design of the simulation platform (Figure 2)

The software design mainly involves application programming of the microprocessor, initialization of SJA1000 (including the setting of initial values such as working mode, filter, interrupt enable register, etc.), monitoring management and keying display. The microprocessor adopts the interrupt working mode to improve the response speed and support the real-time performance of the system. The interrupt flow is shown in Figure 2.

Figure 2 Interrupt flow chart

The core of the software design is the data communication between the microprocessor and the CAN controller. Finally, data communication between CAN network nodes is realized. The programming adopts a modular approach, which is convenient for modification, upgrading and debugging, and supports system flexibility, openness and scalability.

Summary

The CAN bus system node simulation platform based on SJA1000 in this paper has been tested and found to be able to correctly send and receive data between two nodes, and realize the communication between the node and the simulation PC, as well as key input, data display and other functions. Its hardware structure is simple and inexpensive, and its software is flexible, easy to modify, upgrade and further develop networking, etc. Various application systems can be simulated through the simulation PC. Through simulation, the cost and cycle of research and development of CAN bus system are reduced. This simulation platform provides convenient research and development conditions for the promotion and application of CAN bus system in automatic control systems in automobiles and other different fields, and provides a useful reference example for the popularization and improvement of CAN.

Reference address:Implementation of CAN bus system node simulation platform based on SJA1000

Controller Area Network (CAN) is a bus-type serial communication network designed by Bosch of Germany for automobile monitoring systems. It has good networking flexibility, openness, scalability and compatibility. It has strong anti-interference, self-diagnosis, self-monitoring and error correction capabilities, high reliability, simple protocol model structure, good real-time performance, high cost performance and easy development. It is currently the only field bus with international standards. Its application range has far exceeded automobile monitoring systems. It is suitable for distributed automatic control systems in many fields, such as industrial process control and automation, intelligent structure and distributed management, etc., and has become a field bus with great potential for popularization and application.

In order to facilitate the popularization and application of CAN bus in different fields, a simulation platform of the basic component unit of CAN bus system, the node, is developed. Through simulation, the cost and cycle of research and development of CAN bus system are reduced, which is of great practical application value.

This simulation platform uses Philips' SJA1000 chip as the CAN controller. In addition to all the functions of the basic CANPCA82C200 chip standard mode, it also adds a new working mode - PeliCAN mode. This mode supports the CAN2.0B protocol with many new features, such as: stronger compatibility and scalability, stronger error detection and correction capabilities, support for hot plugging, etc. The design is more convenient and flexible, and the chip is low-priced, which is very suitable for use as a general CAN bus system node simulation platform.

In order to meet the needs of automatic control system simulation in various different fields, ordinary PCs can be used as simulators for sensors, actuators, and human-machine keying and display interfaces of various automatic control systems to form a simulation platform and improve the versatility, flexibility and scalability of the nodes. Various application systems can be simulated by simulating PCs.

Hardware design of simulation platform

The hardware system block diagram of the designed CAN bus system node simulation platform is shown in Figure 1.

Figure 1 CAN bus system node simulation platform

The bus system uses low-cost and easy-to-install twisted pair as the communication medium to connect each node into a network system. Each node consists of four functional modules: CAN controller, CAN transceiver, microprocessor and emulated PC.

CAN controller SJA1000 is the core and executes CAN protocol, including data framing and deframing, frame transmission and reception, etc.

Due to the limited bus driving capability of SJA1000, it is connected to the physical bus through CAN transceiver PCA82C250 chip. CAN transceiver converts the logic level signal from CAN controller into a logic level signal suitable for transmission on CAN bus and can be received by CAN transceiver, which plays the role of resisting instantaneous interference and radio frequency interference, increasing communication distance and protecting bus. In order to further enhance the anti-interference capability, high-speed photocoupler 6N137 can be used between SJA1000 and PCA82C250 to realize the level isolation between CAN nodes on the bus.

CAN controller and transceiver cooperate to complete the communication protocol functions of physical layer and data link layer in CAN protocol. Microprocessor 89C51 controls the functions of SJA1000, including initialization and monitoring management, realizes data transmission and reception communication, and executes application layer functions.

The simulation PC realizes level conversion and communication with the microprocessor through the serial port chip MAX232, thereby realizing communication with the CAN bus. The PC can be used as a simulator for sensors, actuators, and human-machine keying and display interfaces of various automatic control systems to form a simulation platform to improve the versatility, flexibility and scalability of the nodes. Various application systems can be simulated by simulating the PC.

Software design of the simulation platform (Figure 2)

The software design mainly involves application programming of the microprocessor, initialization of SJA1000 (including the setting of initial values such as working mode, filter, interrupt enable register, etc.), monitoring management and keying display. The microprocessor adopts the interrupt working mode to improve the response speed and support the real-time performance of the system. The interrupt flow is shown in Figure 2.

Figure 2 Interrupt flow chart

The core of the software design is the data communication between the microprocessor and the CAN controller. Finally, data communication between CAN network nodes is realized. The programming adopts a modular approach, which is convenient for modification, upgrading and debugging, and supports system flexibility, openness and scalability.

Summary

The CAN bus system node simulation platform based on SJA1000 in this paper has been tested and found to be able to correctly send and receive data between two nodes, and realize the communication between the node and the simulation PC, as well as key input, data display and other functions. Its hardware structure is simple and inexpensive, and its software is flexible, easy to modify, upgrade and further develop networking, etc. Various application systems can be simulated through the simulation PC. Through simulation, the cost and cycle of research and development of CAN bus system are reduced. This simulation platform provides convenient research and development conditions for the promotion and application of CAN bus system in automatic control systems in automobiles and other different fields, and provides a useful reference example for the popularization and improvement of CAN.

Previous article:Research on four-way steering gear controller based on CAN bus

Next article:Design and implementation of DS80C390 dual CAN bus hierarchical distributed monitoring system

- Popular Resources

- Popular amplifiers

Latest Industrial Control Articles

- Molex leverages SAP solutions to drive smart supply chain collaboration

- Pickering Launches New Future-Proof PXIe Single-Slot Controller for High-Performance Test and Measurement Applications

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

Guess you like

- [Elective course to get a gift] Keysight's new "Test and Measurement" series of courses, reservations open in the hot summer! Master-level lecturers live online~

- AD chip output digital signal problem

- AVR assembler, paid help

- Allegro software design has been updated with the latest patch, but why can't I do 3D simulation?

- EEWORLD University ---- Embedded Linux Development Introduction Video

- What is a smart WiFi module? What are the types and functions of wireless router gateway control modules?

- Case! EMI rectification of power supply

- Reasons for choosing 4-20mA for flow meter

- WiMax - the new wireless broadband technology

- The US-China patent dispute - MPEG-2 - is over, but what about MPEG-4?

LM146J/A+

LM146J/A+

京公网安备 11010802033920号

京公网安备 11010802033920号