introduction

Since the beginning of the 21st century, the world of information has changed rapidly. Maybe a high-tech product will be released today and a better similar product will be released tomorrow. The update cycle of electronic computer science and technology is about 2 to 3 years. With the development of science and technology such as electronic computers, the modernization and intelligentization of medical equipment has attracted more and more attention. A large number of scientists and engineers have actively participated in this revolution of medical equipment. Among them, the research on various types of X-ray film viewing equipment is also the focus of medical equipment development. Due to the shortcomings of low brightness, poor uniformity, and easy visual fatigue of traditional viewing equipment, it can no longer meet the requirements of modern medical diagnosis. The film viewer developed using CCFL (Cold Cathode Fluorescent Lamp) has the advantages of simple structure, small temperature rise on the surface of the lamp tube, high brightness on the surface of the lamp tube, long service life, good color rendering, and uniform light emission. Medical equipment is crucial. With good medical equipment, some operations that cannot be performed can be performed, and the success rate of the operations that can be performed will be greatly improved.

This article introduces a fully automatic CCFL film viewer brightness adjustment system with C8051F350 microcontroller as the main control chip. When the ambient light intensity changes, the system can keep the ratio of the background illumination intensity of the film viewer to the ambient light intensity at the best, so that the content of the X-ray film seen by the observer is the clearest and less prone to visual fatigue. The ratio of the brightness of the film viewer to the ambient light intensity can be initially set by the observer according to his or her specific situation. The system can also realize the automatic switch of the film viewer. After the X-ray film is inserted, the film viewer will automatically light up. When the system is idle, the film viewer will automatically turn off and enter power saving mode, extending the service life of the cold cathode lamp (which means that there is no need to heat the cathode, but to use the effect of the electric field to control the potential energy change of the interface, so that the electrons in the cathode convert the potential energy into kinetic energy and emit it outward.) It has great advantages compared with the traditional one. It not only ensures the accuracy of the doctor's film viewing, but also ensures the visual fatigue problem of the doctor himself. After all, medical matters cannot be ignored. The doctor's diagnosis results are related to the lives of many people. A little mistake will bring tragedy to one or even several families.

1 CCFL film viewer dimming principle

The film viewer developed using CCFL is an environmentally friendly and energy-saving device that uses a cold cathode high-frequency light source through liquid crystal backlight technology (LCD) to produce a large area of high brightness, good uniformity, and low noise. CCFL backlighting technology is used to transform the line light source into a surface light source with uniform brightness. The CCFL luminous intensity is controlled by a DC/AC inverter, and the CCFL luminous intensity is changed by changing the inverter control voltage. In order to achieve the automatic adjustment of the film viewer to the optimal observation brightness after the ambient light intensity changes, the photoelectric sensor is used to dynamically collect the ambient light intensity, and the C8051F350 performs A/D conversion on the signal. After processing according to a certain algorithm, the CCFL-controlled voltage is output to achieve the purpose of automatic dimming. The medical equipment can provide the light that is most suitable for the environment at the time and the light intensity is stable when working.

2 C8051F35 Introduction

The C8051F350 is a microcontroller that fully integrates a single-chip complex signal system. The C8051F350 integrates a 24-bit 8-channel ADC and an 8-bit 2-channel DAC. The C8051F350 combines highly precise analog data converters with a high-throughput 8051 CPU, making it ideal for analog and computationally intensive applications.

C8051F350 MCU main features:

(1) 8051-compatible CIP-51 core with high-speed pipeline structure, with a maximum execution speed of 50MIPS;

(2) Full-speed non-intrusive system debug interface (on-chip, C2 interface);

(3) 24-bit 1ksps 8-channel single-ended/differential ADC with analog multiplexer;

(4) 2-channel 8-bit current DAC;

(5) High-precision programmable 24.5MHz internal oscillator;

(6) 8KB of in-system programmable FLASH memory;

(7) 768 (512 + 256) bytes of on-chip RAM;

(8) Hardware-implemented SPI, SMBus/IIC and UART serial interfaces;

(9) 4 general-purpose 16-bit timers;

(10) Programmable counter/timer array with 3 capture/compare modules;

(11) On-chip power-on reset, watchdog timer, 2 voltage comparators, VDD monitor and temperature sensor;

(12) 17 I/O ports;

(13) -40~85 degrees industrial temperature range;

(14) 2.7V~3.6V operating voltage, LQFP32 package;

3 Hardware Design

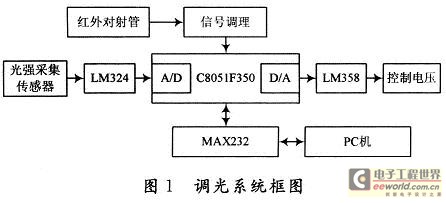

The film viewer control system is mainly composed of three parts: automatic switch, dimming control, and communication interface. The system block diagram is shown in Figure 1. The system uses C8051F350 as the main control chip, and the infrared emitting tube realizes the automatic switch of the film viewer. The single-chip microcomputer realizes the dynamic adjustment of the brightness of the film viewer by real-time acquisition of ambient light intensity and background lighting intensity. The communication part adopts RS 232 interface mode, which mainly completes the setting of system parameters and the in-system upgrade (ISP) of the firmware program.

3.1 Infrared radiator

The automatic switch of the film viewer is realized by the infrared radiating tube sensor. When the X-ray film is inserted between the infrared radiating tubes, the infrared receiving tube outputs a signal, and the program detects the signal and turns on the CCFL; when the system is idle, the film viewer automatically turns off. This can better save electricity and achieve the purpose of low consumption. I believe it will be a great improvement compared with traditional film viewers.

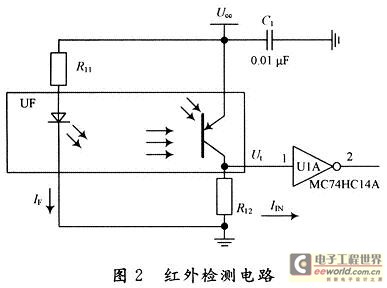

The infrared emitting tube is Honeywell's SEP8505-002, which has an operating wavelength of 935nm, a material of GaAs (gallium arsenide), a luminous power of 7.8mW/cm (lumens), a spectrum width of 80nm, a forward voltage drop of 1.5V, and an output current of 20mA. The infrared receiving tube paired with it is SDP8405-002, with a power of 70mW and a working mode of triode emitter follower output. The output saturation current of the photoelectric receiving tube is 0.4mA, and the saturation voltage of the CE pole is 0.4V. The infrared detection circuit is shown in Figure 2.

3.2 光强信号采集与调理

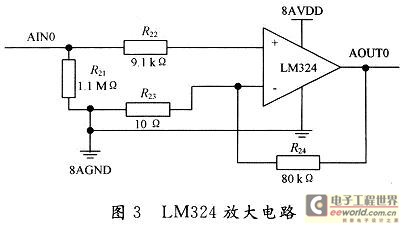

光电传感器在0~50 000 lux范围的照度下产生O~412 mV的电压,而单片机的A/D输入电压范围为O~3.3V,因此系统采用LM324对信号进行放大调理,其放大电路见图3。为实现将0~412 mV的电压放大到O~3.3V的范围,设计放大倍数为8,放大倍数由式(1)确定:

Av=1+R24/R23 (1)

确定R23选择10 kΩ电阻,R24选择80 kΩ电阻。LM324由四个独立的运放组成,为了提高采集光强的准确度,分别用两个光电传感采集CCFL光强,两个采集环境光强,对这四路分别放大后直接输入到C8051F350的高精度AD转换通道0~3进行A/D化处理。

3.3 主控部分

主控芯片采用了美国Silicon Laboratories公司的混合信号ISP FLAsH微控制器C8051F350,其内部有一个全差分24位高精度Sigma-Delta模/数转换器(ADC),该ADC具有片内校准功能,保证了观片仪亮度的高精度动态调节。为实现其系统的稳定性和可靠性,采用模拟和数字分开供电,减少了数字信号和模拟信号之间的干扰。C8051F350主要控制观片仪的自动开关、光信号的A/D转换与处理、控制信号的输出、RS 232串口通信。

3.4 控制信号放大

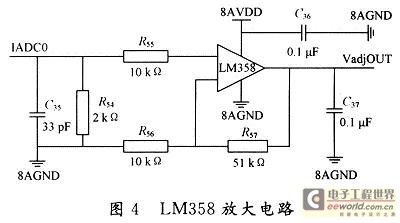

C8051F350内部有两个8位电流方式数/模转换器(IDAC),本系统选用IDACO,能实现O~255范围的微调,保证了系统的精度要求。IDAC0的最大输出电流可以有四种设置:O.25 mA,O.5 mA,1 mA和2 mA。设置IDAC0的满量程输出为0.5 mA,通过2kΩ电阻将电流转化为电压,电压最大可达1V,再经过LM358将电压放大到0~6V后输出,从而实现CCFL的高精度调光设计,如图4所示。

4 实验数据及处理

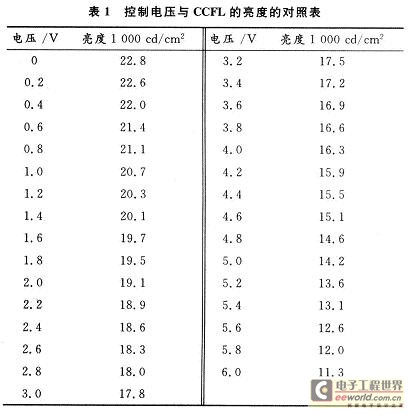

本系统采用2.6×380型号的CCFL和L88亮度计,测量CCFL在O~6 V之间不同控制电压下的亮度,实验结果如表1所示,表中亮度为多次测量的平均值。为实现精确连续流畅的调光,避免传统查表方式存在的精确度差占用存储空间多的缺点,这里采用公式法计算输出控制电压。根据表1,利用最小二乘法求解方程ATAC=ATy,由Matlab数学软件拟合出CCFL控制电压与亮度的关系的表达式为:

U=-10.995 8+3.586 1B-0.233 6B2+O.004 3B3 (2)

式中:U为控制电压值,B为对应的亮度值

5 Software Design

The software design mainly includes the upper computer software and the lower computer program. The upper computer software mainly realizes the setting of necessary parameters such as the optimal contrast of the lower computer, and is written in Visual C++6.0. The lower computer curing program mainly includes the automatic switch module program of the film viewer, the CCFL light emitting voltage control module program, and the RS 232 communication module. The modular design method is adopted, and all modules are interrupt-driven, which improves the efficiency of the system.

The lower computer program mainly cooperates with the hardware to realize dynamic dimming control. The dimming control program realizes dynamic adjustment of CCFL light intensity. According to the traditional method, the voltage and corresponding brightness relationship comparison table is downloaded to the lower computer, and the closest value is found by looking up the table during dimming. The dimming of this system obtains the control voltage by calculation according to the functional relationship between the control voltage and brightness, which saves the storage space of the lower computer, improves the dimming speed and ensures the continuity of the CCFL luminous intensity change. The specific implementation of dimming control is that the A/D with C8051F350 performs analog-to-digital conversion on the currently collected background lighting intensity and ambient light intensity. The ratio of background lighting and ambient light intensity is compared with the set value. If it is greater than the set value, it means that the ambient light is dimming. At this time, the CCFL needs to be dimmed to a certain brightness. If it is less than the set value, it means that the ambient light is getting stronger, and the CCFL luminous intensity needs to be increased. The control voltage of CCFL can be calculated by formula (2), and C8051F350 outputs the control signal to adjust the background lighting intensity of the film viewer.

6 Conclusion

This paper proposes a fully automatic dimming system for cold cathode fluorescent lamp (CCFL) film viewer based on single-chip microcomputer C8051F350. When the ambient light intensity changes, the brightness of the background lighting source of the film viewer is automatically adjusted to achieve the best ratio between the brightness of the film viewer and the ambient light intensity. When the system is idle, it automatically enters the energy-saving state, which greatly improves the service life of the film viewer. The experiment verifies that the control system can realize the automatic switch of the film viewer, and at the same time can effectively ensure that the brightness of the film viewer is automatically adjusted when the ambient light intensity changes, and the ratio of the background lighting intensity to the ambient light intensity is optimal. The experiment shows that the system has well realized the dynamic adjustment of the brightness of the film viewer, and has the characteristics of low power consumption and good stability.

Previous article:Research on multifunctional development platform based on MC9328MX21

Next article:Design and implementation of video server based on embedded WEB

Recommended ReadingLatest update time:2024-11-16 19:52

- Molex leverages SAP solutions to drive smart supply chain collaboration

- Pickering Launches New Future-Proof PXIe Single-Slot Controller for High-Performance Test and Measurement Applications

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- In fact, Valentine's Day 20200214 was cancelled

- This problem occurs when setting up the stm8 environment. What is the reason? Thank you

- dsp28335 data space

- MSP430 MCU Development Record (16)

- I posted a thread about icebabycool. He didn't answer the question but laughed at me instead of showing my low IQ. Please punish this kind of rogue behavior severely.

- Help with POE design issues

- [Voice and vision module based on ESP32S3] Material unpacking—ESP32S3 BOX

- PCBA intelligent detection fixture, one-click generation of test reports

- How to choose the right inductor in a switching power supply

- EEWORLD University Hall----Introduction to Isolated Modulator

Coping with Motion Artifacts by Analog Front-End

Coping with Motion Artifacts by Analog Front-End c8051f350, how to use ferroelectric serial memory FM24C02KEIL C assembly

c8051f350, how to use ferroelectric serial memory FM24C02KEIL C assembly C8051F350 sampling filter assembly program

C8051F350 sampling filter assembly program

京公网安备 11010802033920号

京公网安备 11010802033920号