-

Artificial Intelligence (AI) drives growing energy demand in global data centers

-

New power supply units (PSUs) based on silicon (Si), silicon carbide (SiC) and gallium nitride (GaN) strengthen Infineon’s leadership in AI power supplies

-

World’s first 12Kw PSU gives AI data center operators an edge with improved energy efficiency, power density and reliability

[June 3, 2024, Munich, Germany] The impact of artificial intelligence (AI) has driven the growing energy demand of data centers around the world, highlighting the need to provide efficient and reliable energy supply for servers . Infineon Technologies AG has opened a new chapter in the field of energy supply for AI systems and released a power supply unit (PSU) product roadmap. The roadmap is designed to meet the current and future energy needs of AI data centers while prioritizing energy efficiency.

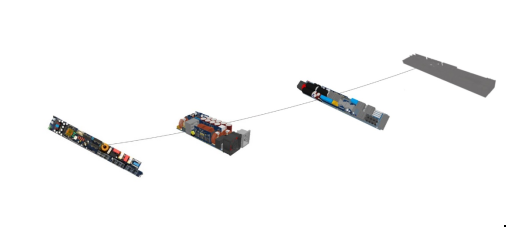

PSU product interface diagram

By achieving higher PSU performance levels, Infineon helps cloud data center and AI server operators reduce system cooling energy consumption. These innovative PSUs reduce power consumption and CO2 emissions, thereby reducing overall operating costs. Powerful PSUs can not only be used in future data centers, but can also replace existing power supply units in servers and improve efficiency.

In addition to the already available PSUs with outputs of 3 kW and 3.3 kW, new 8 kW and 12 kW PSUs will further increase the energy efficiency of AI data centers in the near future. With the 12 kW reference board, Infineon is about to launch the world's first power supply unit that reaches this performance level to power future data centers.

Adam White, President of the Power and Sensor Systems Division at Infineon Technologies , said: “Infineon is powering AI. We are addressing one of the key issues of our time – how to efficiently meet the escalating energy demands of data centers. Infineon’s expertise in integrating three semiconductor materials – silicon (Si), silicon carbide (SiC) and gallium nitride (GaN) – into a single module makes this development possible. As a result, our PSU portfolio not only reflects Infineon’s innovative strength, bringing best-in-class performance, efficiency and reliability to the data center and AI ecosystem, but also consolidates Infineon’s leading position in the power semiconductor market.”

Adam White, President of Power and Sensor Systems Division at Infineon Technologies

Infineon is also responding to data center operators’ demands for higher system efficiency and less downtime. The rise in server and data center applications has increased the demand for power supplies, resulting in the need to develop power supplies with power ratings ranging from 800 W to 5.5 kW and even higher. This growth is due to the increasing power requirements of graphics processors (GPUs) used to compute AI applications.

Currently, the single-chip power consumption of high-end GPUs is as high as 1 kW, and will reach 2 kW or more by the end of the 2020s, which will increase the total energy demand of data centers. According to the International Energy Agency (IEA), by 2030, data center power consumption will account for 7% of the world's total power consumption, equivalent to India's current power consumption.

Despite the rapidly growing energy demand, the new PSUs from Infineon can contribute to reducing CO2 emissions in AI data centers. This is thanks to the extremely high efficiency of the new PSUs, which minimizes power losses. With an efficiency of up to 97.5%, the new generation of Infineon PSUs meets stringent performance requirements. The new 8 kW PSU supports AI racks with a maximum output power of 300 kW or more. Compared to the current 3 kW PSUs with 32 W/in³, its efficiency and power density are increased to 100 W/in³, further reducing system size and saving operators money.

From a technical perspective, this is made possible by the unique combination of three semiconductor materials: Si, SiC and GaN . This technology helps improve the sustainability and reliability of AI server and data center systems. Innovative semiconductors based on wide bandgap materials such as SiC and GaN are the key to rationally and efficiently using energy to promote decarbonization.

The 8 kW PSU will be available in Q1 2025. For more information on the PSU product roadmap,

Previous article:ROHM to participate in PCIM Europe 2024: Enabling growth and driving innovation

Next article:InnoMux™-2 Multi-channel High-precision Flyback Power Supply Application Case Analysis

Recommended ReadingLatest update time:2024-11-15 02:33

- Popular Resources

- Popular amplifiers

-

Application of artificial intelligence technology in the new energy vehicle industry_Wanshun

Application of artificial intelligence technology in the new energy vehicle industry_Wanshun -

Research on non-invasive AI diagnosis method for flyback switching power supply fault

Research on non-invasive AI diagnosis method for flyback switching power supply fault -

【2024 DigiKey Creative Competition】AI Full-Function Environmental Monitoring Station Source Code

【2024 DigiKey Creative Competition】AI Full-Function Environmental Monitoring Station Source Code -

Research on collaborative energy-saving optimization control method for connected hybrid vehicle fleet

Research on collaborative energy-saving optimization control method for connected hybrid vehicle fleet

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- 【Problem feedback】xx is an invalid location...

- Working principle and application of module power supply

- RF/Wireless Popular Data Download Collection

- How to implement wireless video transmission

- 22 power supply R&D issues summarized by senior engineers

- [Me and Atria 3] at32-littlevgl uses gui-guider designer to make a mini-hmi display

- Come if you dare! Enter the top-secret black technology laboratory of Tektronix!

- Share LCD JLX12864G-086 driver based on msp430

- [Image recognition classification & motion detection & analog signal processing system based on Raspberry Pi 400, sixth post - supplement] Raspberry Pi and S...

- EEWORLD University Hall ---- Tsinghua University Altera FPGA Engineer Growth Handbook

Application of artificial intelligence technology in the new energy vehicle industry_Wanshun

Application of artificial intelligence technology in the new energy vehicle industry_Wanshun 【2024 DigiKey Creative Competition】AI Full-Function Environmental Monitoring Station Source Code

【2024 DigiKey Creative Competition】AI Full-Function Environmental Monitoring Station Source Code

京公网安备 11010802033920号

京公网安备 11010802033920号