In electronic devices, the stability of the power supply is very important, and the power supply's ability to suppress ripple noise is equally important. The ability to suppress power ripple noise is usually characterized by the power supply rejection ratio (PSR), which is an important parameter for measuring the stability of the power supply and the ability to suppress interference. It is a parameter that often appears in the specifications of electronic amplifiers (especially operational amplifiers) or voltage regulators.

The Power Supply Rejection Ratio (PSRR) is calculated as the logarithmic ratio of the power supply input ripple and the output ripple. The unit is decibel (dB). The calculation formula is:

Where Vripple (in) is the ripple at the input end, and Vripple (out) is the ripple at the output end. In most cases, Vripple (in) / Vripple (out) is used for calculation, and the PSRR is a positive value; if Vripple (out) / Vripple (in) is used for calculation, the PSRR is a negative value.

From the above formula we can see that:

-

In the same power supply circuit design, the device with larger PSRR is used, and its power supply output is less affected by the power supply;

-

Under the same power supply input ripple conditions, the greater the PSRR of the designed power supply circuit, the smaller the ripple at the power supply output.

PSRR Application Areas

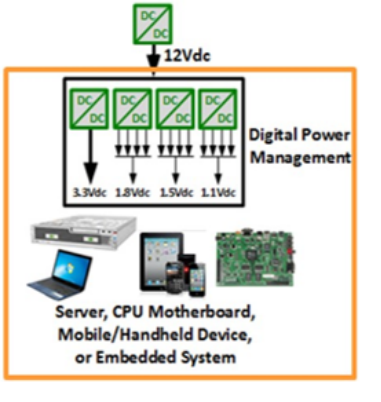

PSRR is widely used in power management chips (PMIC), covering the performance evaluation of devices or circuits including power regulators, amplifiers, etc. Especially in today's typical systems, such as processors (such as GPUs, SoCs, FPGAs), high-speed serial interfaces (such as SerDes, PCIe, USB), high-speed parallel data (such as DDR, LPDDR, GDDR), and low-voltage power supply scenarios where multiple power supplies work simultaneously and require stable power supply and high power interference suppression, the ripple noise on the power rail comes from many factors such as switching noise and harmonics of the power supply, digital signal crosstalk, clock coupling, etc. Since the system is very sensitive to signals, if the power supply's ability to suppress ripple noise is insufficient, it will directly cause signal jitter, generate bit errors, affect system stability, and reduce system efficiency.

All of this makes the ripple noise margin reserved for the power supply smaller and smaller, thus requiring high-precision power supply ripple noise rejection capability (PSRR) measurement. PSRR testing has been widely used in precision industry, automotive electronics, medical equipment and other industries.

Figure 1. Low voltage application scenario

Precision Industry: In the design and application of power regulators, especially LDO power circuits, testing its PSRR performance helps provide a reference for evaluating the power stability of precision low-dropout power supplies. The following Figure 2 shows the necessary PSRR indicators listed on the datasheet of an LDO chip used in digital cameras, mobile phone cameras, wearable devices, etc.:

Figure 2. LDO chip PSRR project (Image from TI)

Automotive electronics: In automotive electronic systems, PSRR measurements of automotive-grade power devices/systems can help to evaluate the stability and safety of electronic devices/equipment under automotive-grade power supply requirements to the greatest extent possible.

Figure 3. Vehicle power system

Medical equipment: In medical equipment, PSRR measurement can help evaluate the impact of power supply noise on the accuracy and stability of medical equipment to minimize the interference caused by power supply noise and ensure the reliability and safety of medical equipment to achieve accurate readings and diagnoses.

Figure 4. Medical equipment power supply system

PSRR Test Application

PSRR is widely used in power management chips (PMIC), covering the performance evaluation of devices or circuits including power regulators, amplifiers, etc. Especially in today's typical systems, which are processors (such as GPUs, SoCs, FPGAs), high-speed serial interfaces (such as SerDes, PCIe, USB), high-speed parallel data (such as DDR, LPDDR, GDDR), and low-voltage power supply scenarios where multiple power supplies work simultaneously and require stable power supply and high power interference suppression, the ripple noise on the power rail comes from many factors such as switching noise and harmonics of the power supply, digital signal crosstalk, clock coupling, etc. The system is very sensitive to signals. If the power supply's ability to suppress ripple noise is insufficient, it will directly cause signal jitter, generate bit errors, affect system stability, and reduce system efficiency.

It is worth noting that with the rapid development of artificial intelligence (AI) technology, the related circuits/devices are showing a trend of extremely low voltage power supply. Testing the PSRR of its power management chip can directly evaluate the power supply's ability to suppress ripple noise, which can be used to reduce system energy loss, improve system performance and efficiency, and help extend the life of the chip.

The figure below shows a memory LPDDR used for artificial intelligence (AI). Its operating voltage has been as low as 0.5V, and the ripple noise margin reserved for the power supply is getting smaller and smaller.

Figure 5. LPDDR memory for artificial intelligence (AI) (Image source: SAMSUNG)

Given its low-voltage power demand and high-throughput characteristics, if it is to ensure continuous operation in high-computing AI application scenarios, a highly stable power supply with high ripple and noise suppression capabilities is a necessary guarantee. What will be the impact if the power supply ripple and noise suppression capabilities are insufficient?

1) Impact on chip data and algorithms: Minor ripple noise in the power supply may cause chip data distortion or chip algorithm errors, affecting the reliability and accuracy of the chip algorithm;

2) Impact on power consumption management and energy efficiency optimization: Chip systems usually require a lot of computing resources, so power consumption management and energy efficiency optimization become key issues. Poor ripple noise suppression directly affects power optimization and reduces system energy efficiency;

3) Impact on RF signal processing stability: In applications that process RF signals to achieve communication or perception functions, power supply ripple noise directly affects communication quality and may cause perception errors.

Figure 6. High-performance chips are susceptible to power supply ripple noise.

How to measure PSRR?

Use an oscilloscope to directly test the ripple at the DUT power input and output and draw the required PSRR curve. Use the Tektronix Mainstream series low-noise and high-resolution oscilloscope system for accurate testing, and connect as shown below:

Figure 7. PSRR test connection diagram

-

Inject a specific frequency sweep signal into the linear injector through the oscilloscope's AFG and then introduce it into the DUT;

-

Use the oscilloscope system to test the ripple at the input and output ends of the DUT power supply respectively;

-

Calculate PSRR value, record data and draw curves through the PSRR function of the oscilloscope

If your power management-related PSRR indicators are always inaccurate, or new power management chip (PMIC)-related products cannot issue datasheets with PSRR indicators on time, affecting the launch of new products, is it possible that the PSRR test solution is not strong enough? On May 22, Chengdu Station | "Core" Friends Meeting Conference invites you to learn more about the detailed interpretation of PSRR testing on site, focusing on the topic: Test misunderstandings of analog chip calibration (economical and efficient PSRR testing).

Previous article:EA Elektro-Automatik Expands Tektronix's High-Power Test and Measurement Portfolio

Next article:[Dialogue with cutting-edge experts] Based on memristor research, looking forward to the future possibilities of system and device collaborative testing

Recommended ReadingLatest update time:2024-11-23 11:03

- Popular Resources

- Popular amplifiers

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- Modern manufacturing strategies drive continuous improvement in ICT online testing

- Methods for Correlation of Contact and Non-Contact Measurements

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- How to use DFT App for hardware accelerated simulation design

- Do you know which fuel gauge has the lowest IQ in the industry?

- Why does this problem occur when the AD16 schematic is imported into the PCB? Can anyone help me solve it?

- GD32E23X Standard Library and GD32E230 Standard Library Manual

- MSP430 MCU Timer A Structure and Application Examples

- CC3200 Kit OURS-SDK-WFB_Explore - by tinnu

- Chip Manufacturing 3-Semiconductor Slicing

- RISC-V IDE MRS Usage Notes (IV): Link-time Optimization

- Notes on capacitor installation

- Xunwei 3399 development board-PCIE 4G module test-compiler

Evaluating Roadside Perception for Autonomous Vehicles: Insights from Field Testing

Evaluating Roadside Perception for Autonomous Vehicles: Insights from Field Testing

京公网安备 11010802033920号

京公网安备 11010802033920号