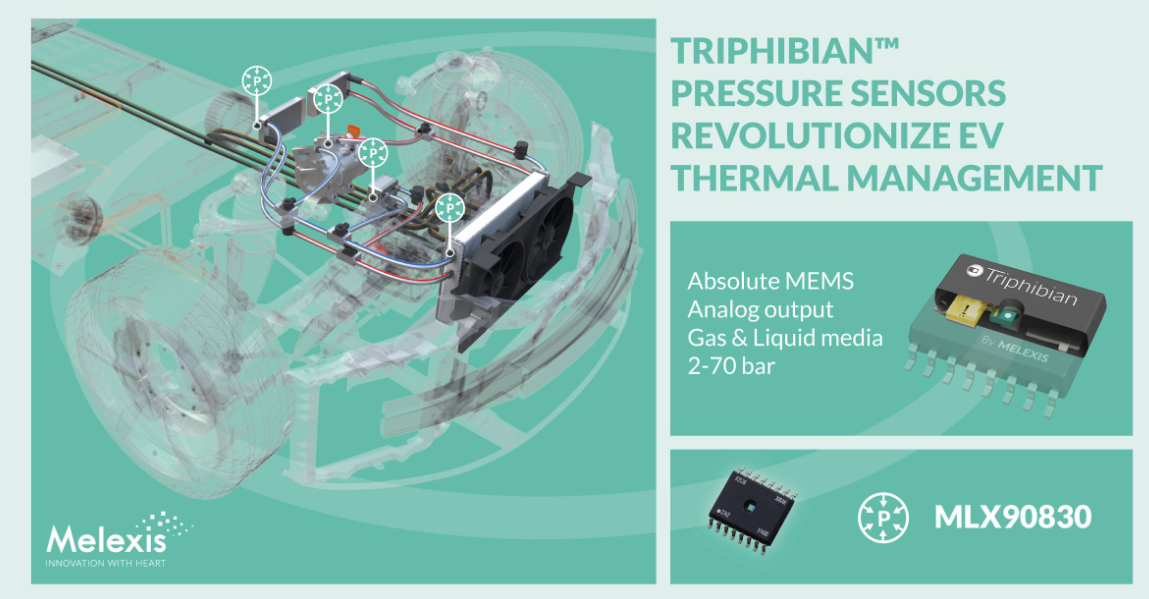

January 19, 2024, Tysendeleau, Belgium - Melexis, a global microelectronics engineering company, today announced the launch of the first pressure sensor chip MLX90830 using new patented Triphibian™ technology . This MEMS pressure sensitive element adopts an unprecedented miniaturization design and can robustly measure the pressure of gas and liquid media in the range of 2 to 70 bar. This device is factory calibrated by Melexis to measure absolute pressure and provide a proportional analog output signal. The MLX90830 simplifies module integration with the latest electric vehicle (EV) thermal management systems, making the module more cost-effective.

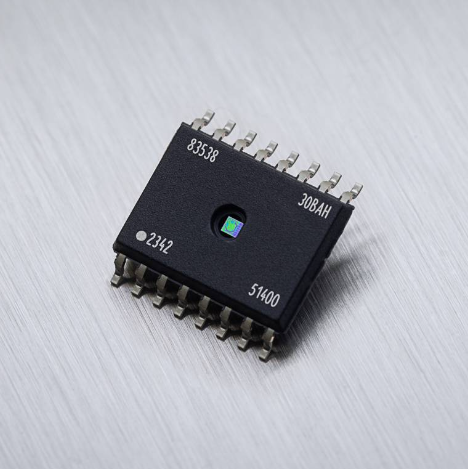

With Melexis' breakthrough Triphibian™ technology at its core, the MLX90830 not only enables MEMS (microelectromechanical systems) sensors to achieve precise measurements well above 5bar, but also enables liquid contact measurements. The MLX90830 is uniquely constructed to achieve an innovative breakthrough, enabling high-pressure sensing while being compatible with gases and liquids. The sensor chip is packaged in an SO16 wide-body package and is equipped with a suspended cantilever with a sensing film on its tip.

The sensor chip's suspended cantilever design provides pressure peak immunity up to 2000bar/msec and static burst pressure levels up to 210bar . The device provides two pressure range calibration ranges (10bar, 35bar) by default. Each pressure range calibration range is specifically tailored to the needs of electric vehicle thermal management systems, including low-pressure and high-pressure refrigeration circuits for refrigerants. The MLX90830 design is more robust compared to backside-exposed solutions because there is still a pressure differential between the glass base side and the wire bonding side. In addition, the pressure equalization principle also applies to cryogenic media, so the MLX90830 can operate in such conditions, which is a first for MEMS pressure-sensitive components.

Compared with existing non-MEMS designs, MLX90830's design is more accurate and robust, helping to optimize the efficiency of vehicle thermal management systems and enabling longer driving distances. In addition, its compact embedded package reduces the size of the sensor chip compared to independent sensor chip modules.

The MLX90830 contains sensors, signal processing circuits, digital hardware, voltage regulators and analog output driver chips. Piezoresistive elements implanted in the sensing membrane form a Wheatstone bridge to generate the output signal. This signal is amplified and converted into a digital signal, temperature compensated through 16-bit digital signal processing (DSP), and finally provided as an analog voltage output through a digital-to-analog converter.

The sensor chip has advanced protection mechanisms to prevent overvoltage (above +40V) and reverse voltage (below -40V), making it ideal for large vehicle applications. MLX90830 is an independent safety unit (SEooC) developed in accordance with the ISO26262 standard and supports ASIL B level system integration to ensure that the latest electric vehicle safety requirements are met.

"Miniaturized MEMS pressure-sensitive components based on Triphibian™ technology and precisely factory-calibrated by Melexis can centralize the thermal management system of electric vehicles, reducing system size and improving reliability." said Karel Claesen, pressure sensor chip product manager, " Customers can design the MLX90830 into a standalone pressure sensor or easily embed it into a system."

"With Triphibian™ technology, MEMS sensor chips can increase the measurable pressure levels and expand the applicable media types." explained Laurent Otte, senior product line manager. "Melexis has solved problems that could not be solved with MEMS technology before. Now we can By measuring the pressure of liquid media, it opens up new possibilities for applications in the automotive industry and other fields."

Previous article:element14 partners with Superior Sensor Technology to deliver innovative pressure sensors

Next article:Now Shipping Analog Devices MAX40109 Low-Power Precision Sensor Interface SoC for Pressure Sensor Applications

- Popular Resources

- Popular amplifiers

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Milestone! SmartSens CMOS image sensor chip shipments exceed 100 million units in a single month!

- Taishi Micro released the ultra-high integration automotive touch chip TCAE10

- The first of its kind in the world: a high-spectral real-time imaging device with 100 channels and 1 million pixels independently developed by Chinese scientists

- Melexis Launches Breakthrough Arcminaxis™ Position Sensing Technology and Products for Robotic Joints

- ams and OSRAM held a roundtable forum at the China Development Center: Close to local customer needs, leading the new direction of the intelligent era

- Optimizing Vision System Power Consumption Using Wake-on-Motion

- Infineon Technologies Expands Leading REAL3™ Time-of-Flight Portfolio with New Automotive-Qualified Laser Driver IC

- Qorvo® Selected as Key Supplier of Wi-Fi 7 FEM for MediaTek Dimensity 9400

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- 【DIY Creative LED】WS2812 Effect Display File

- One watt of GaN is less than one yuan, and it is free shipping by SF Express? Lenovo has launched a price war on GaN.

- B-U585I-IOT02A uses WIFI function

- How many read and write clock cycles does SRAM have?

- Mini OLED Game Console

- How does a trace moisture meter perform for factory equipment testing?

- AT32F425-Evaluation Report-Create Your Own Empty Project 02

- Does anyone have the IPM driver board?

- Oximeter Principle

- Those sneaky tech giants

5962-8964401V2A

5962-8964401V2A

京公网安备 11010802033920号

京公网安备 11010802033920号