Singapore Energy Group builds Singapore's largest industrial cooling system for STMicroelectronics

•Designed and installed by Singapore Power, the industrial district cooling system has a cooling capacity of 36,000 tonnes, making it the largest industrial district cooling system in Singapore.

•This move will bring a number of benefits, including saving 20% in cooling-related electricity consumption and reducing carbon emissions by up to 120,000 tons per year

•The project will last for 20 years and is valued at US$370 million.

On May 23, 2022, China --- STMicroelectronics (ST), a world-leading semiconductor company serving multiple electronic applications, and SP Group, a leading utility group in the Asia-Pacific region and operator of Singapore's national grid, announced the signing of a cooperation agreement , whereby the latter will build a district cooling system (DCS) for STMicroelectronics' AMK TechnoPark in Singapore. The project is valued at US$370 million, with a service period of 20 years, and is scheduled to be officially put into use in 2025. By then, it will become Singapore's largest industrial project district cooling system.

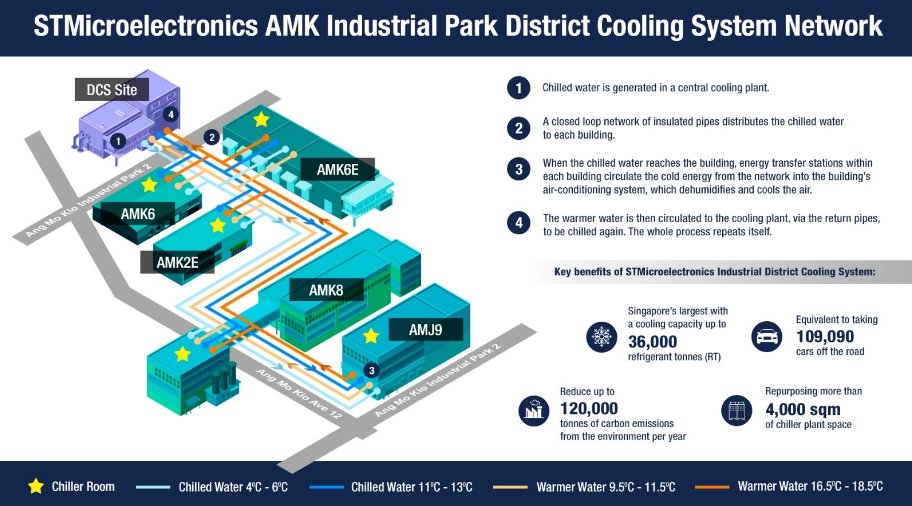

According to the agreement, Singapore Power Group will design, build, own and operate the district cooling system and provide chilled water services to meet the cooling needs of STMicroelectronics' production workshops and office spaces. The system has a cooling capacity of up to 36,000 refrigeration tons (RT). By improving the energy efficiency of the cooling system, it can help STMicroelectronics save 20% of cooling-related electricity consumption each year, and reduce carbon emissions by up to 120,000 tons per year for STMicroelectronics' Singapore Technopark factory, which is equivalent to removing 109,090 cars from the road. There are two ways to achieve carbon reduction in this project. One is to reduce cooling-related electricity consumption, and the other is to reuse more than 4,000 square meters of space in the original cooling equipment room when the cooling system is officially operational, and better help achieve decarbonization by installing solar energy and perfluorinated compound (PFC) emission reduction equipment.

Ms Low Yen Ling, Minister of State for Trade and Industry and Culture, Community and Youth of Singapore, attended the signing ceremony as a special guest.

“The private sector has an important role to play alongside public and people power in advancing Singapore’s climate and sustainability goals. By taking sustainable actions, such as improving energy efficiency, businesses send a strong signal to their partners and customers that sustainability issues are urgent and serious action is needed. At the same time, businesses can use sustainability as a competitive advantage,” she said.

She further added: “I hope this initiative will inspire more innovative carbon reduction solutions in other industrial developments and motivate more companies to pursue opportunities in sustainability.”

The cooling system will be the first district cooling system implemented by STMicroelectronics in its global production facilities. STMicroelectronics has committed to achieving carbon neutrality worldwide by 2027. The use of district cooling in STMicroelectronics' largest wafer fab by volume is a key enabler for meeting the Minimum Energy Efficiency Standards (MEES) required by Singapore's National Environment Agency (NEA) and a key factor in achieving ST's sustainability goals.

Rajita D'Souza, President of Human Resources and Corporate Social Responsibility at STMicroelectronics, said: "The Singapore factory cooling system will be the first district cooling system deployed in ST's global production facilities, and it is our commitment to ST's global carbon neutrality goal by 2027. The district cooling system used in our largest single wafer processing plant (by output) will reduce carbon emissions by 120,000 tons, which is equivalent to 30% of STMicroelectronics' total carbon emissions in Singapore in 2021. The deployment of this district cooling system will be a key driver of the plant and the company's sustainability goals."

“ District cooling is a key sustainable energy solution that can support a low-carbon future for cities, townships, and industrial parks , ” said Mr. Wee Thian Guan, Group President of Singapore Power. “ To help decarbonize Singapore’s industrial sector, we have tailored this solution to support energy-intensive manufacturing projects like ST’s TechnoPark, as they build on their sustainability strategy to reduce their energy consumption and carbon footprint. With our comprehensive suite of sustainable energy solutions, including solar and EV charging, we look forward to working with ST to help them achieve their net-zero goal.”

Notes to Editors:

In Singapore, district cooling is gaining industry attention as an innovative solution to redesign building internal cooling systems to make them more sustainable while reducing carbon footprint. The solution centrally produces chilled water and then distributes it through pipes to district buildings to cool air conditioning systems and process flows. District cooling has four major benefits: improved energy efficiency, reduced cooling costs, freed up building space for commercial use, and reduced carbon emissions.

Previous article:U.S. Secretary of Transportation visits Velodyne Intelligent Infrastructure Solutions (IIS) deployment

Next article:BOE (BOE Technology Group) launched its full media control platform in Chengdu Metro. Innovative IoT technology helps upgrade digital media

Recommended ReadingLatest update time:2024-11-15 13:54

- e-Network Community and NXP launch Smart Space Building Automation Challenge

- The Internet of Things helps electric vehicle charging facilities move into the future

- Nordic Semiconductor Launches nRF54L15, nRF54L10 and nRF54L05 Next Generation Wireless SoCs

- Face detection based on camera capture video in OPENCV - Mir NXP i.MX93 development board

- The UK tests drones equipped with nervous systems: no need to frequently land for inspection

- The power of ultra-wideband: reshaping the automotive, mobile and industrial IoT experience

- STMicroelectronics launches highly adaptable and easy-to-connect dual-radio IoT module for metering and asset tracking applications

- This year, the number of IoT connections in my country is expected to exceed 3 billion

- Infineon Technologies SECORA™ Pay Bio Enhances Convenience and Trust in Contactless Biometric Payments

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Brief Analysis of Automotive Ethernet Test Content and Test Methods

- How haptic technology can enhance driving safety

- Let’s talk about the “Three Musketeers” of radar in autonomous driving

- Why software-defined vehicles transform cars from tools into living spaces

- How Lucid is overtaking Tesla with smaller motors

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Three steps to govern hybrid multicloud environments

- 8. [Learning LPC1768 library functions] Timer experiment

- One minute to understand: World Industrial History (video explanation)

- EEWorld's "Search Device" applet is now online, allowing you to easily check device data and make chip selection easier

- Wireless transmission distance calculation

- How to amplify small signals with the ATA-5000 series preamplifier?

- LOTO Lesson 4: Practice of the common emitter amplifier circuit of transistor 2N3904

- Ahhhh urgent help, please help me analyze the simple circuit diagram

- Inventory of several commonly used protection circuits

- 4G Small Base Station

- [AT-START-F403A Review] Part 1: Newbie Unboxing Experience

Characteristic Modes——Theory and Applications in Antenna Engineering

Characteristic Modes——Theory and Applications in Antenna Engineering

京公网安备 11010802033920号

京公网安备 11010802033920号