How to choose the right level of integration to meet motor design requirements?

Source: InternetPublisher:念慈菴 Keywords: Motor Design Updated: 2025/01/16

If you are designing a motor drive application, you may have traditionally used multiple discrete components such as bipolar junction transistors (BJTs) to implement motor control. Although this approach is generally less expensive, the total number of components used is higher, which takes up more board space, takes longer to design, and is more complex. Using multiple components can also affect system reliability.

As applications grow in complexity, power increases, and space decreases, integration becomes critical. Integrated solutions can reduce design time, simplify procurement, and save costs while ensuring that motor systems are more reliable and efficient.

In this article, I will compare different motor control implementations, including discrete and fully integrated options, to help you find the right approach for your design. Table 1 compares the level of integration of various motor control options.

Table 1: Integration level for driving motors

Taking a discrete approach to motor control

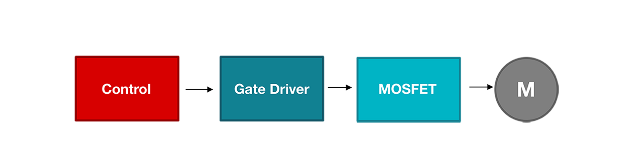

Figure 1 shows a control unit such as a microcontroller (MCU) processing feedback on the motor status and sending signals to adjust the motor's torque, position, and speed. The gate driver amplifies the signal from the MCU to drive the motor's metal oxide semiconductor field effect transistor (MOSFET).

Figure 1: Basic motor control block diagram

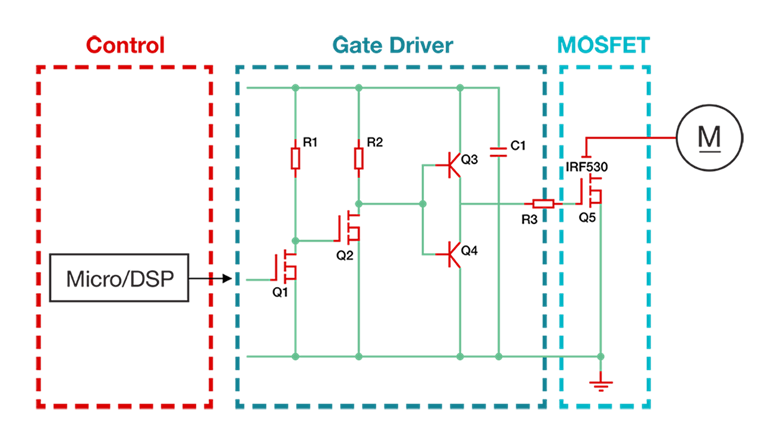

You can use a BJT totem pole/push-pull circuit as a gate drive circuit to drive a single MOSFET, as shown in Figure 2. Although this method is low cost and easy to implement, the BJT totem pole circuit requires a large number of external components and occupies a large board space. In addition, you must replicate this discrete circuit because you need multiple MOSFETs to drive the motor, which multiplies the number of components and board space required.

Figure 2: Block diagram of a gate driver using a discrete BJT totem pole/push-pull circuit

The first integrated option: gate driver IC

Basic gate driver ICs integrate the functionality of a totem pole into a single package. Recent innovations in process technology have made gate driver ICs as affordable as discrete BJTs.

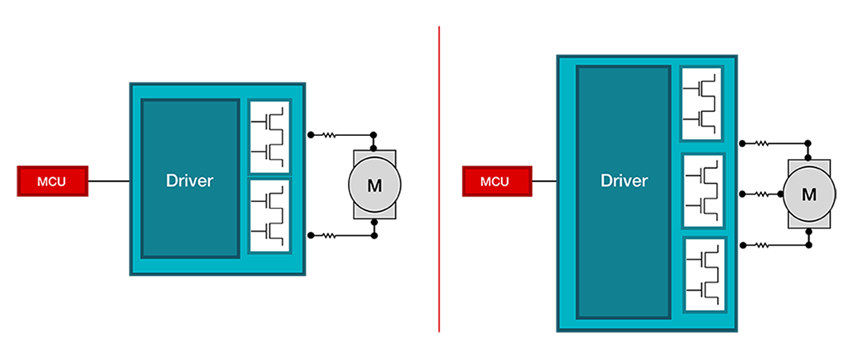

There are several considerations to consider when selecting a gate driver IC, such as the number of channels and the voltage and current capabilities that best suit the motor power level, as shown in Figure 3.

The integrated gate driver IC includes:

Single-channel gate drivers, such as the UCC21732 from Texas Instruments (TI), are commonly used to drive AC motors with high-side and low-side high-voltage (>700V) power switches such as insulated gate bipolar transistors (IGBTs) and silicon carbide (SiC).

Dual-channel half-bridge gate drivers (such as the UCC27712) for 100V to 700V motor driving of IGBTs and MOSFETs

Four-channel H-bridge drivers and six-channel three-phase motor gate drivers (such as DRV8329) designed for low-voltage MOSFET (<60V) DC motors

As motor power levels change, using gate drivers allows the previous design to be maintained while only changing the external FETs to accommodate the new voltage and current levels.

Figure 3: Types of gate driver ICs driving external FETs

The gate drivers range from those with basic features such as undervoltage lockout and interlock protection to prevent cross-conduction, to those with advanced features such as smart gate drive technology for slew rate control and automatic dead-time control. For more information on these gate drivers, refer to the “Understanding Smart Gate Drive” application note.

Traditionally, the slew rate is set by the following external components: two source and drain resistors (to limit the current in the MOSFET gate), a diode (to adjust the rise and fall rates independently), and a pull-down resistor. With smart gate drive technology, these components are no longer required, and the slew rate can be flexibly adjusted through the serial peripheral interface.

The six-channel driver uses smart gate drive technology to eliminate the need for up to 24 discrete components, saving board space and reducing the bill of materials (BOM). The gate driver also integrates other protection and diagnostic functions, including current sensing, overcurrent and overtemperature protection, fault detection and even isolation, which further reduces component count.

Second integration option: Motor driver IC

Motor driver ICs include gate drivers and integrated FETs, making them ideal for low-power motor systems (<70W), as shown in Figure 4. Compared to gate drivers, motor driver ICs take up less space; they integrate the FET power stage, simplifying design schematics and layout. Like gate driver ICs, motor driver ICs (such as the DRV8962) also integrate protection and diagnostic features.

Figure 4: H-bridge and three-phase motor driver with integrated FETs

When selecting a motor drive solution, it is important to consider the RDS(ON), peak current, and RMS current of the internal FETs. Thermal calculations also need to be performed to account for the power dissipation of the internal FETs.

Third integration option: Integrated control gate driver IC

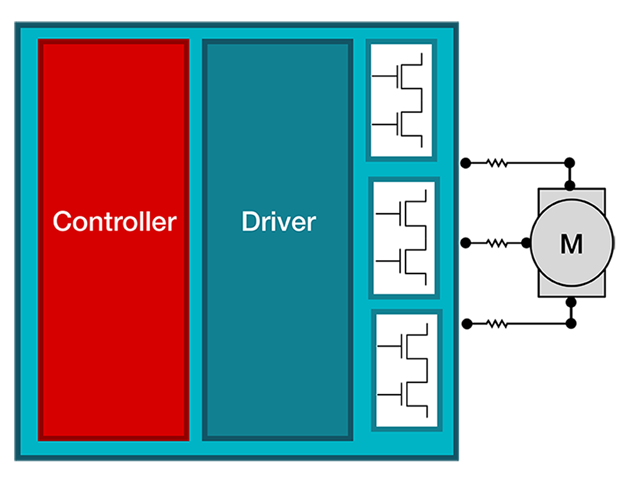

Unlike the first two options, integrated control gate driver ICs such as the MCT8329A do not require an MCU for motor control. These ICs still feature gate drivers with protection and diagnostics, while incorporating control algorithms without the assistance of an MCU, as shown in Figure 5.

The implementation of motor commutation algorithms can be complex, whether trapezoidal, sinusoidal, or field-oriented control. Integrated control gate driver ICs provide a code-free solution that handles the commutation algorithms internally, helping you reduce design time and simplify the complexity of coding, debugging, and testing.

Figure 5: Integrated control of three-phase gate drivers

Integrated control gate driver ICs provide the flexibility to implement motor commutation through sensor control or sensorless control. With the sensor control method, an external Hall effect sensor can be used to detect the rotor position; these ICs can use the Hall effect sensor input and use the motor control algorithm to drive the motor quietly and efficiently. In contrast, with the sensorless control implementation method, no external Hall effect sensor is required, thus reducing board space and BOM. If a sensorless integrated control gate driver IC is selected, the back electromotive force (back EMF) voltage needs to be measured through integrated current sensing and the motor position is calculated internally.

Fourth integration option: Integrated control, gate driver and FET IC

The final integration option is often referred to as “full integration” and is shown in Figure 6. An integrated control, gate driver, and FET IC, such as the MCF8315A, combines codeless control functions, drivers with protection and diagnostics, and FETs in a single chip, thereby taking up less board space and reducing BOM. Similar to the motor driver IC option, the integrated control, gate driver, and FET IC solution is limited by the capabilities of the internal FETs, so current and thermal calculations are required.

Figure 6: Fully integrated - motor control, driver and FETs

Conclusion

These different levels of ICs not only meet the power level requirements of motors, but also reduce design time, cost and complexity. Integrated devices can also solve the challenges of audible noise in home appliances and high-precision control in factory automation and robotics.

- Tutorial on making your own remote-controlled robotic arm

- How to remotely control devices using ESP8266 and LPC2148

- Peripheral circuit of automotive motor controller power supply chip

- An automated model railroad layout project using a microcontroller

- Controlling stepper motors with wireless remote control transceiver and PE-51 board

- Motor control circuit for starting and running without phase loss

- Design and analysis of touch delay switch circuit composed of CD4011 and CD4001

- Audio interface protection circuit

- Infrared detection alarm

- Night dog barking anti-theft reminder circuit

- PLC light source robot hand bubble control circuit

- 24h automatic switching capacitor control circuit

- Multi-pole leakage protector circuit a

- Digital current loop control circuit

- Neon light control circuit

- Automatic sprinkler irrigation control circuit

- Water dispenser (Aucma) temperature detection control circuit

- Micro DC motor steady speed control circuit b

- DC motor forward and reverse control circuit

- Apply LOGO! Electric gate control circuit b

京公网安备 11010802033920号

京公网安备 11010802033920号