On September 7, Toyota Motor announced that it expects to invest approximately US$13.5 billion in power battery research and development and supply chain construction by 2030. In 2030, the annual battery production capacity could exceed 200GWh.

Toyota Motor CTO Masahiko Maeda said that Toyota has been working hard to reduce manufacturing costs and improve the endurance of lithium batteries used in plug-in hybrid electric vehicles (PHEV) and pure electric vehicles (EV).

In terms of batteries, Toyota has reduced production costs by 30% or more by improving battery materials and structures. NiMH batteries and lithium-ion batteries used in hybrid (HEV) models will continue to evolve and upgrade based on the characteristics of the two batteries.

Toyota's bipolar nickel-metal hydride battery released this year has excellent instantaneous explosive power and will be installed in more models in the future. Lithium-ion batteries used in PHEVs and EVs will focus more on reducing costs and improving durability. To this end, Toyota is stepping up research and development, hoping to provide an upgraded version of the new lithium-ion battery after 2025.

Toyota's new Aqua, released in July this year, uses a new bipolar nickel-metal hydride battery developed jointly with Toyota Industries. This battery innovatively adopts a bipolar structure to achieve practical use of a driving vehicle battery. Compared with the battery installed in the old Aqua, the output density has increased by 2 times, making acceleration more powerful.

Regarding the next generation of EV batteries, the upcoming TOYOTA bZ4X draws on Toyota's EV technology, which has been continuously developed since the launch of the RAV4 EV in 1996, as well as the latest technologies related to HEV batteries and electrified vehicles. Toyota hopes to reduce battery capacity by reducing power consumption, and strives to reduce costs by more than 30% through the development of materials and structures.

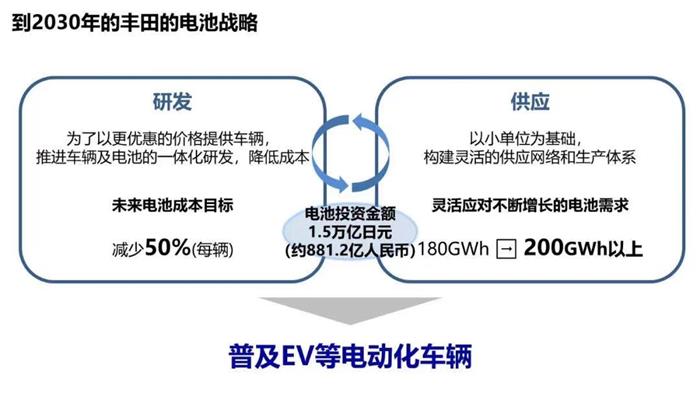

For the whole vehicle, starting with the TOYOTA bZ4X, we will gradually reduce the power consumption per kilometer to achieve a 30% reduction. Through these research and development of vehicle and battery integration, we hope to achieve the goal of reducing the battery cost per vehicle by 50% compared to the TOYOTA bZ4X by 2030.

Regarding all-solid-state batteries, Toyota is considering developing batteries with high power, long driving range, and short charging time. In June last year, an electric vehicle equipped with all-solid-state batteries manufactured by Toyota was tested on a test route. It is now at the stage of obtaining vehicle driving data. After improvements based on these data, in August last year, the electric vehicle equipped with all-solid-state batteries officially obtained a license and began driving experiments.

During the development process, Toyota learned that the ions in the all-solid-state battery will move at high speed in the battery, thereby achieving high power output. This feature will be able to be used in HEVs to give full play to the advantages of all-solid-state batteries.

On the other hand, there is also the issue of short battery life, and we need to continue researching and developing solid electrolyte materials. By continuously discovering problems, we will strive to realize the practical application of all-solid-state batteries.

In addition, Toyota has also updated its power battery production capacity target. It is expected that by 2030, through the integrated development of vehicles and batteries, the cost of each vehicle will be reduced to less than 50%. In terms of supply, it will respond flexibly according to the changing needs of consumers. For example, when the popularity of electric vehicles exceeds expectations, Toyota will further increase production capacity and provide batteries with a capacity of more than 200GWh, higher than the 180GWh currently being discussed.

Toyota plans to invest about 1.5 trillion yen (about 88.12 billion yuan) in the improvement and research and development of its battery supply system from now until 2030. Toyota's partners in power batteries include CATL, Fudi Battery, Panasonic, Sony, Toshiba and other companies.

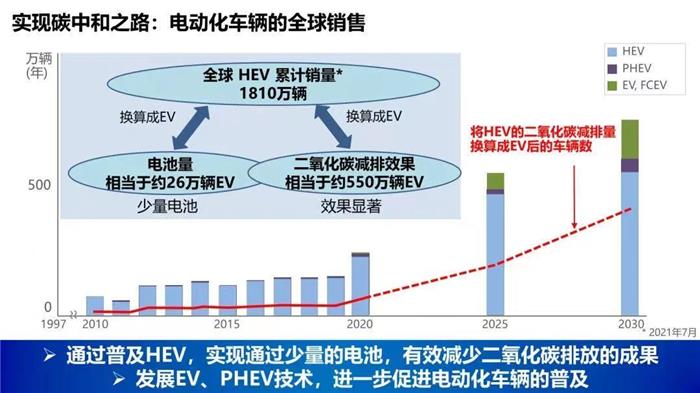

Toyota Motor said that by 2030, the company's annual sales of electric vehicles will reach 8 million. Among them, pure electric vehicles (BEV) and fuel cell vehicles (FCEV) will reach 2 million, and the remaining 1 million will be hybrid (HEV) models. This means that Toyota's electrification transformation is still mainly HEV, which is very different from the goal of Volkswagen, Daimler, BMW, GM and other giants to fully switch to pure electric.

According to Toyota's calculations, the carbon dioxide emissions reduction effect of every three HEVs is equivalent to that of one EV. HEVs are now relatively cheaper. For regions where renewable energy is about to be popularized, making full use of the electrification of HEVs can effectively reduce carbon emissions. For regions that already have abundant renewable energy, it is very important to accelerate the popularization of zero-emission vehicles such as EVs and FCEVs.

Toyota believes that the solution is to reduce carbon emissions, or how to get carbon emissions as close to "zero" as possible. Different regions have different energy conditions and different options for reducing carbon dioxide emissions. In order to expand the options for achieving carbon neutrality, it is necessary to actively try various solutions. Based on the above ideas, Toyota is promoting all-round electrification business to provide different regions with "sustainable and practical vehicles" that can meet customer needs and reduce carbon dioxide emissions.

Previous article:Eaton collaborates with Ballard and NREL on heavy-duty truck fuel cell technology

Next article:Deputy Secretary-General of the China Internal Combustion Engine Society: The gap between Chinese and foreign hybrid technology is reflected in four aspects

- Popular Resources

- Popular amplifiers

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- How much do you know about intelligent driving domain control: low-end and mid-end models are accelerating their introduction, with integrated driving and parking solutions accounting for the majority

- Foresight Launches Six Advanced Stereo Sensor Suite to Revolutionize Industrial and Automotive 3D Perception

- OPTIMA launches new ORANGETOP QH6 lithium battery to adapt to extreme temperature conditions

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions

- TDK launches second generation 6-axis IMU for automotive safety applications

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Detailed explanation of intelligent car body perception system

- How to solve the problem that the servo drive is not enabled

- Why does the servo drive not power on?

- What point should I connect to when the servo is turned on?

- How to turn on the internal enable of Panasonic servo drive?

- What is the rigidity setting of Panasonic servo drive?

- How to change the inertia ratio of Panasonic servo drive

- What is the inertia ratio of the servo motor?

- Is it better for the motor to have a large or small moment of inertia?

- What is the difference between low inertia and high inertia of servo motors?

- RedMonk Programming Language Survey: Python Remains at No. 2

- What is the functional difference between these two capacitors?

- Embedded Engineer Recruitment-Beijing-This post is valid for a long time

- 【GD32E231_DIY】-06 SYN7318 speech recognition module information

- 3 Ways to Speed Up Your Design Cycle Using Brushless DC Motors

- EEWORLD University Hall----Live Replay: TI's new generation C2000? microcontroller integrates powerful communication capabilities and control performance to achieve more flexible system-level design

- Twinkly Earwarmer Headband

- [Evaluation of domestic FPGA Gaoyun GW1N series development board]——(3) Use of Modelsim

- Design of LED emergency lighting controller based on MSP430

- CPU (Computer) Load Monitor

LM741T

LM741T

京公网安备 11010802033920号

京公网安备 11010802033920号