WiTricity has an MIT background and specializes in developing electromagnetic resonance wireless charging technology for consumer, industrial, medical and military applications. The company's CEO Alex Gruzen said that the wireless charging equipment developed by Witricity has reached the level of electric vehicles, with a maximum power of tens of kilowatts, exceeding the 3.3 or 6.6 kilowatts currently available on the market.

In addition to this new technology, WiTricity has also updated its leadership team in recent months, starting with the appointment of Gruzen as the new CEO in April, replacing Eric Giler, who successfully built the company's business foundation and strength during his more than five years in office. Giler will continue to serve as a member of WiTricity's board of directors. The new CEO Gruzen previously served as a senior executive at Dell, HP, Compaq, and Sony.

At the same time, WiTricity also hired Farooq Butt, who previously served as vice president and senior vice president of global business development at Dell, and Donald Peck, who previously served as EVP and CFP at Lojack Group, as its new CFO.

While updating its leadership team, WiTricity continues to invest more money ($25 million last year) to enter the automotive industry, working with partners such as Delphi, Toyota, IHI, Mitsubishi, and TDK.

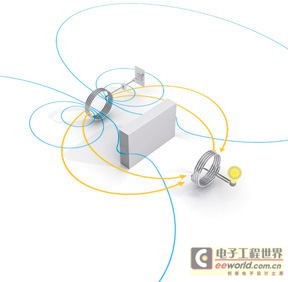

WiTricity's technology is based on the sharp resonant strong coupling of electromagnetic fields, which can efficiently transfer electric power even at distances several times the size of the device itself. It is a non-radiative energy conversion that works on the electromagnetic near field. Specially designed electromagnetic resonators are unique to this technology and can efficiently transfer power over long distances in the form of electromagnetic near fields. The electric field can bypass conductive obstacles between the power source and the receiving device, so the power exchange is not affected.

The efficiency of power exchange depends on the relative size and distance between the power source and receiving device. The maximum efficiency is achieved when the distance between the devices is not large, and can reach 95%.

Alex Gruzen said: "Since the founding of the company, WiTricity has never stopped the research and development and commercialization of electromagnetic resonance technology. At the beginning, we even used three feet of wide copper wire as the material. From 2005 to now, we have made great progress. We provide customized solutions, ranging from low-cost devices with a few millivolts, to compact level, to kilowatt-level products for electric vehicles."

High power version

In addition to the 3.3 kW product for low-end electric vehicles, a new 6.6 kW product was later developed, and now the number has been raised to several dozen kW. It is a widely applicable technology. As battery prices decrease and sizes increase, more powerful charging equipment will be developed to keep pace with the automotive industry.

Gruzen also said that wireless charging technology, including public infrastructure, is also very attractive for plug-in hybrid vehicles. "The convenience it provides is huge. In plug-in hybrid vehicles, the battery size is generally not large. Every time the user of this type of vehicle drives home and parks in the garage, they will hesitate: Do I need to charge this time? When the battery is not full, the fuel consumption of this type of car is difficult to reach the ideal level. With wireless charging, these small batteries can be automatically charged every time they stop, and it is easy to keep them fully charged, which greatly improves the user experience."

WiT-3300 Developer Kit

For plug-in vehicles, WiTricity offers its partners the WiT-3300 developer kit with a highly efficient wireless “stop and charge” system.

WiT-3300 provides up to 90% efficiency at a power level of 3.3 kW (the same power as most wired devices). Wireless charging supports a ground clearance of 10 to 20 cm, while providing user customization possibilities for higher or lower ground clearances. Any type of non-metallic material can be installed between the power source and the receiving device, so the power source device can be installed under the garage floor and covered with materials such as cement, asphalt, etc.

The WiT-3300 device does not require the power source and the receiving device to be completely aligned to charge efficiently. Compared with traditional wireless charging devices based on electromagnetic induction, this strongly coupled electric field resonance energy transfer method makes the system size four times smaller and the weight twice as small, while also being more efficient.

Other optional equipment includes Foreign Object Detection (FOD) sensor and Live Object Detection (LOD) biosensor to improve the safety of the charging process.

FOD system: Located inside the power source housing, it detects foreign metal objects and metal fragments that may affect charging and automatically stops charging when foreign objects are found to prevent metal electrothermal effects.

LOD system: It detects animals and humans within the working range and can automatically stop charging when necessary.

Previous article:Will the future arrive? Five questions about Qualcomm's wireless charging technology

Next article:Design of a regional Zigbee network for low-cost urban parking guidance system

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Wireless charging | Complete explanation of wireless charging technology principles/applications!

- The legendary Starlink

- EEWORLD University: How to use GaN to design reliable, high-density power solutions

- [Sipeed LicheeRV 86 Panel Review] Four Debian Python+Tk Calculators

- The relationship between LoraWAN, LPWAN and Lora

- Looking for PD Sink controller solution

- Making solar inverters more reliable than the sun

- EEWORLD University - Basic Knowledge of Welding

- micropython update: 2020.4

- [Fudan Micro FM33LG0 Series Development Board Review] Fudan Microchip uses J-Scope waveform software to accelerate product development

LTC2050IS5#TRM

LTC2050IS5#TRM

京公网安备 11010802033920号

京公网安备 11010802033920号