Keywords : Fluorometer, Software Development, Energy Spectrum

In recent years, X-ray fluorescence analyzers have been widely used in building materials, metallurgy, mining and other industries. They can perform rapid and non-destructive physical analysis of the composition and content of materials or products. The analysis results depend not only on the various technical indicators of the instrument, but also on the analysis method used. Therefore, since the successful development of X-ray fluorescence analyzers, both internationally and domestically, the research on analysis methods and software development has become the main research content to improve the analysis accuracy of instruments and expand the scope of use. In recent years, with the continuous development of fieldbus technology, traditional chemical analysis methods have gradually been replaced by modern electronic measurement and analysis instruments because they cannot realize digital automatic input. This article combines practical experience to explore the energy spectrum analysis method and software development for quantitative analysis of material components of X-ray fluorescence analyzers used in automated production bus structures.

1 Energy spectrum analysis

1.1 Basic measurement principle

When high-energy photons (X-rays) or high-speed charged particles bombard atoms in the sample, they transfer part of their energy to the atoms, thereby exciting electrons at certain energy levels in the atoms, and the holes in the atoms are filled by electrons in the outer orbits, and the excess energy is released in the form of X-rays. The X-ray photons emitted by various elements have different characteristic energies, which are called the X-ray characteristic rays of the element. Therefore, by bombarding the sample with continuous X-rays to produce a fluorescence spectrum, and then detecting, identifying and analyzing the characteristic spectrum through a multi-channel pulse amplitude analyzer composed of a single board and a computer, the element composition in the sample can be qualitatively or quantitatively analyzed. The analysis results are directly transmitted to the central control room via the bus to achieve true closed-loop control. Its structural block diagram is shown in Figure 1:

1.2 Spectral data processing

As shown in Figure 1, the energy spectrum pulse signal obtained by the X-ray detector enters the microcomputer system through the amplifier and multi-channel analyzer. The computer processes the conventional data of the X-ray energy spectrum through software, thereby performing qualitative and quantitative analysis on the content of the sample. Spectral data processing includes: smoothing of the original spectrum data; automatic peak search and determination of the energy of the peak position: qualitative analysis of the elements to be measured: determination of the peak boundary channel; peak area calculation, etc.

(1) Smoothing preprocessing of original spectrum data

Due to the statistical principle error of the measurement process, the X-ray spectrum form has the characteristics of statistical fluctuations. The statistical error of the obtained X-ray spectrum is more obvious. When searching for peaks, the statistical fluctuation of the count may be mistaken for a spectrum peak, so the spectrum needs to be smoothed preprocessed first. This system uses the second-order polynomial five-point smoothing method. The specific calculation formula is:

![]()

where n

i-2

, n

i-1

, n

i+1

, and n

i+2

are the counts of the i-th channel to be smoothed before and after smoothing. When smoothing the spectrum, it can be repeated several times to achieve the desired smoothing effect.

(2) Automatic peak search:

Finding the peak position from the acquired X-ray spectrum and converting it into the corresponding energy is the basis for qualitative analysis of X-ray energy spectrum. This software system uses the comparison method as the method for automatic peak search by computer. The specific method is as follows:

If the count of the i-th channel satisfies the following inequality:

![]()

then the peak position is considered to be in the i-1, i, i+l channels, and then the channel with the largest count is selected from these three channels as the peak position. k is the peak search threshold, which is generally taken as 1-1.5.

(3) System energy scale:

The energy scale determines the relationship between the channel address m and the X-ray energy E of this measurement system. That is,

![]()

after automatic peak search, the peak position m of the characteristic X-ray is obtained, and the X-ray energy corresponding to the peak position can be solved by substituting it into (3). After searching and verifying with the element characteristic X-ray energy library one by one, the type of element to be measured can be determined.

(4) Determination of peak boundary channel:

Accurate calculation of the net peak area of the characteristic peak is the basis for quantitative analysis. To this end, the boundary channel address of the characteristic peak must be determined according to the actual situation. Since the semiconductor detector used has good energy resolution, clear spectrum peaks can generally be obtained for elements with higher content. Therefore, we use the full width of the spectrum peak as the basis for determining the background count.

(5) Net peak area calculation

This system uses the Watson method to calculate the net peak area (Figure 2). Take point F within the peak boundary L and H as the width of the background calculation (F is also called the area factor), β

1

and β

2

are left and right.

2 Software Development

2.1 Software System Composition

The software system is the basis for energy spectrum analysis to achieve qualitative and quantitative analysis of material elements, and is also an important part of the "fluorescence analyzer". This system uses Windows 98 as the working platform and Microsoft Visual C++ 6.0 as the development tool.

(1) Software System Block Diagram

The computer is connected to the hardware multi-channel pulse amplitude analyzer (MCA) through an interface, and the conversion results are directly sent to the computer through the interface part, and the computer completes the acquisition, display, processing and data communication. The entire software system mainly includes file management, data acquisition, spectrum data display, data communication, energy calibration, coefficient calibration, spectrum analysis and other parts. Its structure is shown in Figure 3.

(2) Main classes

This software is a multi-task system. During the software design, different "classes" are established to manage various tasks. The following is a brief introduction to the main "classes" established in the software:

(1) Main frame class. Mainly completes the generation of toolbars, status bars and the main interface dialog box of each module.

(2) Application class. Mainly completes the creation of document module class and starts the application.

(3) Document class. Mainly completes the functions of spectrum data management. Such as opening and saving spectrum data files; energy scale; spectrum analysis calculation. ?

(4) View class. Mainly completes the functions of screen display. Such as spectrum line display; content display; highlight operation; data acquisition, etc.

(5) Subframe class. Completes functions related to the frame window.

According to needs, in addition to the above main classes, this software also includes many dialog box classes established for obtaining user input. For example: edit element library dialog box class, manual content calculation dialog box class, coefficient calibration dialog box class. Peak search and resolution dialog box class, energy scale dialog box class, select measurement sample type dialog box class, set acquisition parameter dialog box and serial port data communication class, etc.

2.2 Introduction to the functions of the main modules

(1) Spectrum data display module?

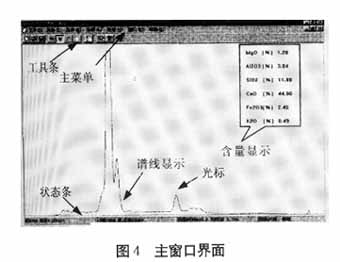

The software system adopts the Windows standard window interface, which is mainly composed of the menu bar, tool bar, status bar, spectrum display area, etc. The window is shown in Figure 4.

The menu bar includes the main function items such as file, acquisition, display, analysis, and view. Clicking on the items in the menu bar will pop up a drop-down menu.

The toolbar has added the most commonly used function buttons. For example, start measurement, stop measurement, clear data, sample transfer, energy scale, etc.

The status bar displays the channel address, energy, count, ordinate size, measurement time, measurement status, etc. of the current cursor. In the measurement display area, in order to facilitate observation of data during measurement, the full spectrum is directly displayed in the form of spectrum lines to monitor the overall measurement situation. The content display area is in the upper right corner of the main window. After each sample measurement, the content is updated. During the measurement process, the analysis content of the previous sample can be displayed.

The software is a multi-document user window that can open multiple spectrum files at the same time, which is convenient for comparison and viewing of several spectrum lines.

(2) Data acquisition module

The data acquisition module includes five parts: parameter setting, start measurement, stop measurement, clear data, and control sample transfer. Data is transmitted between the system and the multi-channel pulse amplitude analyzer through the parallel port.

(3) Energy scale module

Energy scale refers to the relationship between channel address and energy. After testing the standard element samples, the channel address and energy in this instrument have a good linear relationship, so a straight line is used to describe the energy calibration curve.

(4) Coefficient calibration module

X-ray fluorescence analysis is based on the principle that the peak area of the characteristic ray peak of the element being analyzed in the sample is proportional to the content of the element in the sample. Before analyzing the sample, coefficient calibration must be performed first, that is, to establish a working curve between the peak area of the characteristic peak of the element being analyzed in the sample and the chemical analysis result of the element.

(5) Spectrum analysis module

The spectrum analysis module includes: peak search, spectrum smoothing, content calculation, etc.

(6) Data communication module

In the automated production line, the proportion of ingredients is based on the sample analysis results returned by the sample analysis system to the overall control system, and then the overall control system sends a control command to the automatic feeding system to adjust the ingredients. This software system uses a communication protocol with the overall control system to complete the transmission of sample analysis result data to the bus control system through the 485 interface, thereby realizing automatic closed-loop control of the entire production system. After the sample measurement is completed, the system immediately analyzes it. When the control system issues a data acquisition command to the system, the system immediately responds and transmits the analysis results to the control system.

(7) File management module:

When each measurement is completed, the system can automatically save the sample spectrum data and analysis result files in the corresponding folder according to the sample type selected by the user.

3 Verification of system analysis accuracy:

This system is used for cement raw material analysis, and the results are compared with chemical analysis in Table 1.

(1) Practice has proved that the analysis method of this system is simple, fast and accurate. Compared with the chemical analysis results, its measurement accuracy and repeatability average arithmetic deviation meet the design requirements. ?

(2) The system can collect, display and automatically process sample X-ray spectrum data in real time, and can save full spectrum data files and calculation result data files to facilitate information exchange and archiving. ?

(3) Using Modbus communication protocol, the digital transmission of sample analysis results with other control parts of the automatic production line is realized through the 485 interface.

References:

[1]Mark Andrews 著.Visual C++自学指南[M].北京:清华大学出版社,1997

[2]李瑞城,等.X射线光谱分析的原理和应用[M].北京:国防工业出版社,1983

[3]谢中信,等.X射线光谱分析[M].北京:科学出版社,1982

[4]赵保经.A/D和D/A转换器应用手册[M].上海:上海科学普及出版社1995

[5]刘培奇,席一凡,等.Visual C++ for Windows面向对象程序设计[M].西安:西安电子科技大学出版社,1996

Previous article:USB host function in embedded applications

Next article:HDMI Standard Chat: 10.2G is a Fake Bandwidth

- Popular Resources

- Popular amplifiers

- High signal-to-noise ratio MEMS microphone drives artificial intelligence interaction

- Advantages of using a differential-to-single-ended RF amplifier in a transmit signal chain design

- ON Semiconductor CEO Appears at Munich Electronica Show and Launches Treo Platform

- ON Semiconductor Launches Industry-Leading Analog and Mixed-Signal Platform

- Analog Devices ADAQ7767-1 μModule DAQ Solution for Rapid Development of Precision Data Acquisition Systems Now Available at Mouser

- Domestic high-precision, high-speed ADC chips are on the rise

- Microcontrollers that combine Hi-Fi, intelligence and USB multi-channel features – ushering in a new era of digital audio

- Using capacitive PGA, Naxin Micro launches high-precision multi-channel 24/16-bit Δ-Σ ADC

- Fully Differential Amplifier Provides High Voltage, Low Noise Signals for Precision Data Acquisition Signal Chain

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Today's live: TI uses DLP pico projection technology to design augmented reality smart glasses

- Laser driver circuit

- Looking for Windows XP SP3 ghost system!

- After the epidemic, will companies continue to work overtime like crazy?

- [RVB2601 Creative Application Development] CDK Development Environment Simple Application Experience Sharing

- How to embed OS in MSP430 series MCU

- Repost - The other side of electronic components you have never seen!

- 【CH579M-R1】+Drive LSM303DLH Magnetic Field Sensor

- BKP backup register

- msp430 to tft

EL8176IS-T7

EL8176IS-T7

京公网安备 11010802033920号

京公网安备 11010802033920号