1 Introduction

The traditional instrument for measuring blood pressure is the mechanical mercury sphygmomanometer. Electronic sphygmomanometers have only appeared on the market in recent years. Compared with traditional sphygmomanometers, electronic sphygmomanometers are simple to operate and easy to use, but their accuracy and stability are often not ideal. This design strives to be accurate and stable, so that it is suitable for the elderly or patients to monitor their blood pressure at any time and for clinical medical testing.

2 System Hardware Design

This design uses Motorola's MPX53GC silicon pressure sensor and TI's MSP430F149 single-chip microcomputer as the main components to form an electronic blood pressure meter. The system structure is shown in Figure 1. The system consists of MCU, sensor, LCD display, operation panel, charging and discharging control circuit, air pump and air valve, buzzer, storage, power supply and other parts.

2.1 Microprocessor Selection

The single-chip microcomputer is the brain of the whole system. It not only monitors the system and processes the data, but also adjusts the hardware parameters by judging the measurement results, so that the system can automatically adjust to the best working state and has a certain degree of intelligence. According to the design requirements of the system, the MSP430F1 49 single-chip microcomputer of TI company is selected.

MSP430 has built-in ADC12, which is a 12-bit A/D converter with high speed and universal features. ADC12 can convert one of 8 external analog signals or one of 4 internal voltages. ADC12 has a universal sampling/holding circuit, which provides users with various choices of sampling timing. MSP430F149 microcontroller can well meet the requirements of system design.

2.2 Sensor circuit design

MPX53GC is a Motorola X-type sensor. This type of sensor is low-priced, has excellent linearity, low noise, fast response, and has temperature compensation when powered by a constant current source. The composition of the sensor circuit is shown in Figure 2. The output signal of the pressure sensor first passes through the filter circuit and then is amplified. At the same time, the microcontroller MSP430F149 will generate a 1:10 pulse width to control the sawtooth wave generator, generate a sawtooth wave and compare it with the processed pressure signal, and convert the level signal into a pulse width signal. The microcontroller MSP430F149 measures the pulse width, and then converts it into systolic pressure (SP), diastolic pressure (DP), and mean pressure (MP) through corresponding calculation processing.

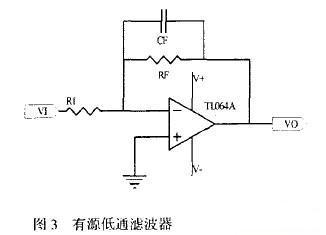

2.3 Filter circuit design

In the process of blood pressure measurement, since the signal output by the sensor MPX53GC is extremely weak and mixed with high-frequency noise, if the circuit design is unreasonable, the weak signal will be drowned by the noise. Therefore, in each stage of the amplifier circuit, there should be a corresponding noise filtering or suppression circuit. In addition, the coupling of distributed capacitance and distributed inductance should be eliminated as much as possible, and shielding should be performed where necessary. As shown in Figure 3, an active low-pass filter is used to effectively weaken high-frequency noise and appropriately amplify the signal. Its frequency function can be expressed as:

2.4 Design of charging and discharging control circuit

The charging and discharging circuit is also an important factor affecting the measurement accuracy. Therefore, how to control the charging and discharging valves is the key to get the best measurement results. During the measurement process, we use the single-chip microcomputer MSP430F149 to control the charging and discharging rate, and control the action of the charging and discharging valves according to the pressure. This can not only accurately control the charging and discharging rate, but also monitor the operation of the entire system. In addition, it can also avoid some accidental human injuries.

The control process is shown in Figure 4 and the inflation circuit is shown in Figure 5. During the inflation process, you can inflate a little faster and estimate the systolic and diastolic pressures to calculate the deflation rate. When the maximum value is reached, stop inflating and start to deflate slowly and evenly. During the deflation process, PWM pulse width modulation is used for control, and the pressure of the blood pressure cuff CUFF is always detected to maintain a uniform deflation rate. Finally, when the pressure is less than 20mmHg, all deflation valves are immediately opened.

2.5 LCD display module design

This system uses LCD driver HT1621, which is a 128 (32 × 4) segment LCD driver that can drive multiple LCD screens. Its interface with the microcontroller is shown in Figure 6. The interface only requires four lines. The line is used to initialize the serial interface circuit and terminate the communication between MSP430F149 and HT1621. Data write/write and command write are transmitted through the data line. RD read signal, the data in the RAM is sent to the data line at the falling edge of the RD signal, so that the MSP430F149 reads the correct data between the rising edge of the RD signal and the next falling edge.

A WR is a write signal. Data, addresses and commands on the data line can be written into the HT1621 on the rising edge of a WR signal. IRQ is an optional control.

2.6 Power Module Design

The system is powered by two 1.BY batteries, which are boosted to 3.5V by the XC6382 chip to directly provide power to the system.

3 Software Design

The software part is the core of the effective operation of the entire system. The system can only work properly when the software and hardware are organically combined.

3.1 Acquisition and control program module

It completes the functions of collecting data (pressure sensor signals, key signals, etc.), controlling inflation and deflation, etc. Its program flow is shown in Figure 7.

3.2 Data processing and display module

The data processing and display module completes the digital filtering of the pressure sensor data, calculates the systolic pressure, diastolic pressure, mean pressure and pulse, and then stores the corresponding data in the EEPROM (24C256) and displays it on the LCD screen (HT1621). The program flow chart is shown in Figure 8.

4 System calibration

The measurement system needs to be calibrated, and the electronic sphygmomanometer is no exception. There is a special pressure calibration program in the software system, which is used to help the debugger to debug. The debugging process is as follows: give the system zero pressure (that is, let the sensor connect to the atmosphere), and after a period of stability, the system automatically records the pulse width at zero; then prompt the debugger to give the system a pressure of 300mmHg. At this time, the debugger should adjust the displayed value to within 16268±100, and the system is calibrated.

5 Conclusion

Through a series of analysis, research and improvement, the system design has better met our test requirements. During the measurement process, the person being measured should remain motionless, otherwise a false pulse signal may be formed due to the person's movement, and the CP signal may be changed. In order to further improve accuracy and reliability, sensor linearity, PCB board wiring, air pump and air valve selection, etc. need further research and improvement.

Previous article:Design of intelligent monitoring system for office buildings based on MSP430F149

Next article:Basic knowledge about interface technology

Recommended ReadingLatest update time:2024-11-16 22:19

- Popular Resources

- Popular amplifiers

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

Professor at Beihang University, dedicated to promoting microcontrollers and embedded systems for over 20 years.

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- 【GD32L233C-START Review】Driver of serial digital tube display module

- Shanghai recruits photoelectric sensor digital front-end design engineers (400,000-600,000)

- Qorvo and UWB AOA to develop together

- [TI recommended course] #MSP430 capacitive touch technology- waterproof Demo demonstration#

- FPGA Advanced Timing Synthesis Tutorial.pdf

- MOSFET selection for USB PD+TYPE-C fast charging power supply

- About CRC check

- AX5201 is used as an LED driver circuit with 4.5V input and 12V output, and it is likely to be damaged.

- How to deal with impedance continuity of PCB traces?

- FPGA Design Tips

Microcontroller Principles and Applications Tutorial (2nd Edition) (Zhang Yuanliang)

Microcontroller Principles and Applications Tutorial (2nd Edition) (Zhang Yuanliang) MSP430F149 examples and programs

MSP430F149 examples and programs

京公网安备 11010802033920号

京公网安备 11010802033920号