0 Introduction

Target drones are an important branch of the UAV family. They are mainly used to simulate threat targets such as combat aircraft and missiles, and provide realistic aerial targets for air defense weapon system testing and training. With the advancement of technology, modern anti-ship missiles mostly adopt the "ultra-low altitude sea-skimming" flight penetration method. Correspondingly, unmanned target drones used to simulate anti-ship missile targets also need to have ultra-low altitude sea-skimming flight capabilities. In the 1960s, Western developed countries represented by the United States launched the first generation of target drones with ultra-low altitude sea-skimming and fixed altitude flight capabilities. After that, they quickly formed a series and continued to upgrade with the application of new technologies. Some classic models are still widely used today, such as the Stone Chicken, Fire Bee, Mirachi and other series of target drones, whose relative altitudes of sea-skimming flights have reached less than 5 m. China started late in this field. The flight control system is the "brain" of the UAV. The ultra-low altitude sea-skimming flight of the UAV is mainly achieved under the control of the altitude controller of the flight control system. Therefore, this paper aims at the development of a small target drone flight control system. Based on the basic principle of radio altimeter/accelerometer combined control, this paper adopts Kalman filter signal processing method and an embedded system based on ARM7 microprocessor to design a simple and practical altitude controller that can accurately control the flight altitude of the target drone, thereby achieving the purpose of ultra-low altitude fixed flight over the sea.

1 Flight control system configuration and altitude control principle

The target drone flight control system consists of three parts: sensors, flight control computers and actuators. The sensors mainly include vertical gyroscopes, two-axis angular rate gyroscopes, three-axis strapdown magnetic heading sensors, radio altimeters, vertical accelerometers, pitot tubes, GPS receivers, engine temperature and speed sensors, etc. The flight control computer is the core component of the flight control system. It is an embedded computer based on ARM7. It receives measurement information from various sensors, solves according to the control law, and gives control signals to drive the actuators to act. The actuators mainly include elevator servos, aileron servos, rudder loop controllers, engine throttle motors and ECU controllers. The flight control system composition is shown in Figure 1.

The altitude controller is mainly composed of two feedback control loops, inner and outer. First, the vertical gyro and angular rate gyro measurement signals are used as feedback control signals to form the target aircraft attitude control inner loop (angular motion control system), including two control channels, lateral and longitudinal, which are the core control loops of the system. Since the attitude control system has an attitude angle static error under the interference of a constant disturbance torque (such as vertical wind), it will cause altitude drift and cannot be directly applied to the stability and control of the altitude trajectory. Therefore, it is necessary to directly measure the aircraft altitude and vertical motion speed and other linear motion information in the altitude control system. Using sensors such as altimeters and linear accelerometers, an altitude control outer loop is established on the basis of the attitude control system. The two together constitute a complete altitude control system (the shaded part in Figure 1). When flying at ultra-low altitude, a high-precision altitude sensor is required, usually a radio altimeter. In the actual design of the system, a radio altimeter and a linear accelerometer are used for combined control, that is, after the measurement information of the radio altimeter and the vertical linear accelerometer is processed by a specific algorithm, two feedback control signals of the target aircraft altitude and vertical speed are obtained and sent to the longitudinal attitude control channel to form an altitude control outer loop, which together with the attitude control inner loop completes the altitude control function.

2 Altitude control law design

2.1 Basic control law design

In order to reduce design risks, the altitude control law adopts the classic proportional-differential (PD) control.

Its time domain representation is:

Its control principle is shown in Figure 2.

The control quantity consists of four parts, including two control quantities for the attitude control inner loop and the altitude control outer loop. Attitude control inner loop: The proportional controller proportional to the pitch angle deviation △θ is used as the main control to correct the pitch angle, and the differential controller proportional to the pitch angle rate θ is mainly used to improve the damping characteristics of the attitude inner loop.

Altitude control outer loop: The proportional controller proportional to the height difference △H is used as the main control to correct the height, and the differential controller proportional to the vertical velocity Ran is mainly used to improve the damping characteristics of the altitude outer loop.

2.2 Signal processing method and effect analysis

After the basic control law is determined, a major problem that must be solved is how to obtain high-quality feedback control signals. The pitch angle deviation △θ and the pitch angle rate θ can be provided by the vertical gyro and the angular rate gyro to provide signals that meet the accuracy requirements. The main problem here is the acquisition and processing of the altitude signal H and the vertical velocity signal H. The radio altimeter signal itself contains a lot of noise due to the influence of factors such as sea waves. If the altimeter signal is directly differentiated to obtain the vertical velocity signal, it will cause system instability and cannot be used alone. If the accelerometer signal is integrated to obtain the vertical velocity signal and the height signal, there is an error accumulation problem and it cannot be used alone. However, if the two are used in combination, a good complementary effect can be produced. Therefore, this paper adopts a Kalman complementary filtering algorithm, which can not only filter out the height signal noise, but also obtain high-quality vertical velocity signals. The design idea is to obtain the vertical velocity by integrating the vertical acceleration signal, and then obtain the height by integrating the vertical velocity. This height is compared with the actual measured height of the altimeter to obtain a deviation. The deviation is added back to the vertical acceleration and vertical velocity as the error estimate at the current moment to continue the filtering operation. The principle of complementary filtering of the height signal and the vertical acceleration signal is shown in Figure 3.

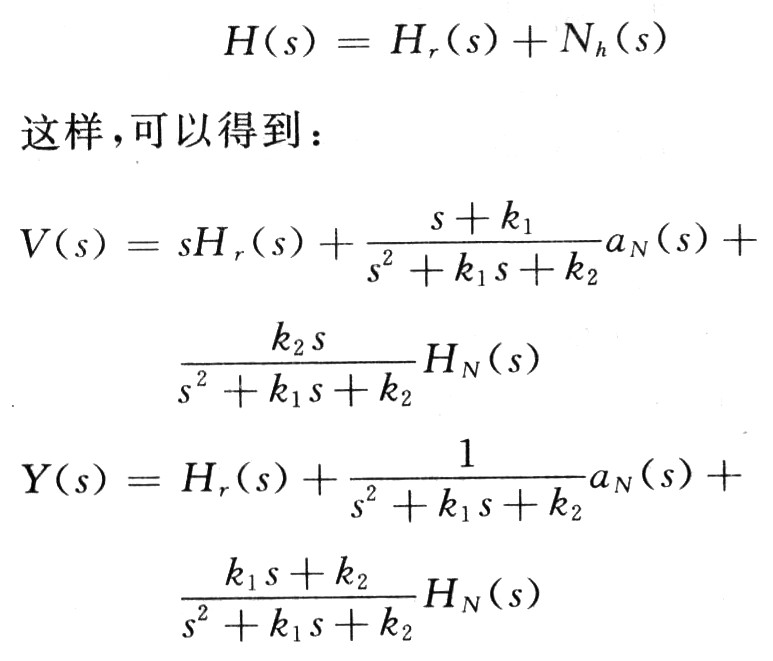

The effect of the filtering algorithm is analyzed. Assume that the actual height of the drag target is Hr, and record a=Hr+Na, where Na represents the error of acceleration, then:

Record H=Hr+Nh, Nh represents the error of height, then:

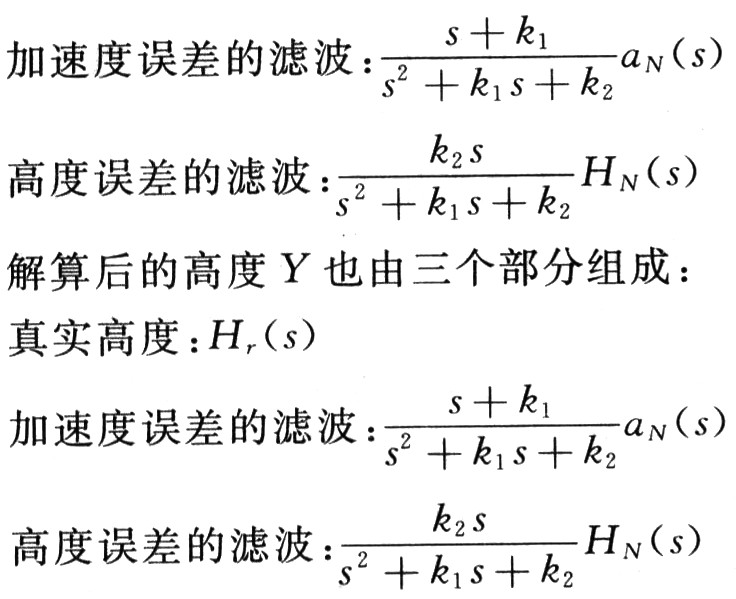

As can be seen from the above, the calculated velocity V consists of three parts:

the differential of the true height: sHr(s)

In the vertical velocity and height signals thus obtained, the acceleration error and height error signals can be effectively filtered, and in particular, the influence of sea clutter can be effectively removed.

3 Controller hardware and software design and implementation

The altitude controller is part of the target drone flight control system. It takes the flight control computer as the core and forms a closed-loop control system together with various sensors and execution structures. It is mainly composed of flight control computer, vertical gyro, angular rate gyro, radio altimeter, accelerometer, rudder loop controller, servo and other equipment.

(1) Flight control computer

The flight control computer includes the main board, A/D conversion board, serial data communication interface board, switch interface board, D/A conversion board, analog input pre-processing board, discrete input/output and optoelectronic isolation/driver board, DC/DC power conversion board, etc. It adopts ARM-based embedded system design, which has the advantages of small size, low power consumption, rich hardware resources, easy development, good real-time performance and reliability. The mainboard processor uses the 32-bit LPC2124 chip with ARM7TDMS-S architecture. Its 16 KB internal RAM and 128 KB internal FLASH memory can well meet the operating requirements of the embedded real-time operating system RTOS (μC/OS-Ⅱ), ensuring that the system can solve the altitude control law once every 20 ms.

(2) Vertical gyro

The TC-3E vertical gyro is selected. It is mainly used to measure the pitch angle attitude of the aircraft in the altitude control loop. The working range of the pitch angle is ±30° and outputs an analog voltage signal.

(3) Angular rate gyro

The 2-axis angular rate gyro is selected. It is mainly used to measure the pitch attitude angular velocity of the aircraft in the altitude control loop. The pitch angular velocity output range is ±60°/s and outputs an analog voltage signal.

(4) Radio altimeter

It adopts frequency modulation/continuous wave (FM/CW) system, with an operating frequency of 4200~4400 MHz, a height measurement range of 0~300 m, and an altitude output form: RS 232 serial port output, a baud rate of 38400 b/s, and an update rate of 50 Hz.

(5) Accelerometer The accelerometer

is installed at the center of gravity of the target aircraft and is used to measure the vertical acceleration of the dragged target. The ADXL105AQC accelerometer chip is selected, with an accuracy of ±1~±5 g, single-channel analog output, and a resolution of 2 mg.

(6) Rudder loop controller

It is designed based on the PWM DC motor driver dedicated integrated circuit L292. It includes a position regulator, a current regulator, a PWM power amplifier, a position feedback and a current feedback sensor. The position feedback is the main feedback loop, using a WDL-25 direct-slide precision conductive plastic potentiometer; the current feedback uses a standard resistor.

(7) Elevator servo

A gear-reduced permanent magnet DC torque motor is used, with a rated torque of 15 Nm and a rated speed (after deceleration) of 4±1 r/min.

(8) Software design

The application is written based on the embedded real-time multi-tasking operating system μC/OS-Ⅱ, which has the characteristics of portability, tailoring, multi-tasking and priority-based preemptive task scheduling, good real-time performance and high reliability. The real-time operating system (RTOS) is used because the application can be decomposed into multiple tasks, which simplifies the design of the application software. At the same time, RTOS ensures the real-time performance of the control system; a good multi-task design helps to improve the stability and reliability of the system.

4 Semi-physical simulation experiment and results

The developed small unmanned target aircraft altitude control system was simulated and verified on the self-built UAV semi-physical simulation platform. The aircraft model adopts the six-degree-of-freedom nonlinear full-volume motion equation, the basic simulation step is 5 ms, and the simulation calculation accuracy is 64 b (double-precision floating point). The simulation system includes the vertical gyro and angular rate gyro on the three-axis turntable, and the airspeed sensor connected to the dynamic and static pressure simulator. The radio altimeter signal and accelerometer signal are simulated by the computer and then connected to the altitude control computer, steering gear, etc. to form a simulation loop. The simulation results are shown in Figures 4 and 5. This paper gives the results under two main interference conditions.

The simulation results show that under the influence of altimeter noise and accelerometer measurement error caused by level 4 sea conditions, the system can control the target drone to smoothly enter the 14 m fixed altitude flight state and maintain the flight at the predetermined altitude according to the accuracy requirements. Under the interference of 5 m/s vertical wind, the target drone can quickly return to the predetermined 14 m reference altitude. It can be seen that the static and dynamic response indicators of the system can meet the design requirements.

5 Conclusion

Based on the radio altimeter/accelerometer combined control mode, this paper adopts the mature proportional-differential (PD) control principle, the signal processing method of Kalman complementary filtering, and the hardware implementation based on ARM and the software development of μC/OS-Ⅱ embedded real-time operating system. The ultra-low altitude sea-skimming flight altitude controller of a small target drone is designed. Its structure is simple and compact, and the principle is feasible. The semi-physical simulation experiment results show that the system has good static and dynamic response characteristics, and is fully capable of controlling the ultra-low altitude high-precision sea-skimming flight of the target drone. The system design and hardware and software implementation are successful.

Previous article:Design and implementation of automatic shearing machine control system

Next article:Design of controller for air source heat pump water heater

- Popular Resources

- Popular amplifiers

- Molex leverages SAP solutions to drive smart supply chain collaboration

- Pickering Launches New Future-Proof PXIe Single-Slot Controller for High-Performance Test and Measurement Applications

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Try STM32MP157A-DK1 for free. Come and try it out!

- 【Silicon Labs Development Kit Review】+ Environment Construction and Understanding SSV5

- EEWORLD大学堂----TI DLP? Labs - Automotive - DLP for head-up display applications

- Shanghai ACM32F070 development board evaluation, unboxing, environment construction, lighting up the LED light, making the LED flash

- An article about Qorvo's layout in mobile phones

- XMC4800 Relax EtherCAT Kit is now available and we are planning to launch a promotion! Who wants this board?

- Entrepreneurship Hero Post (Partners for technology-based startups)

- Short circuit, help needed

- A brief description of the stack structure in the ZigBee standard

- Digital voltmeter based on ADC0832

LMV721MWC

LMV721MWC

京公网安备 11010802033920号

京公网安备 11010802033920号