Remote patient monitors running low on power? Recommended power supply design elements

The Internet of Things (IoT) revolution has brought about a paradigm shift in the way medical institutions provide real-time patient care. Among them, remote patient monitoring is an important area where new medical devices are changing the way doctors and patients interact. With the miniaturization of integrated circuits and the evolution of wireless technology, traditional medical devices have been transformed, their functions have been enhanced, and patient compliance and efficacy have gradually improved.

Challenges from power supply

Currently, remote patient monitoring patches have replaced traditional bulky Holter devices. The various sensors contained in the patches can collect heart rate, temperature and accelerometer data, and can transmit patient data to the cloud for real-time access by patients and doctors. Although these patches help doctors improve their nursing capabilities, they pose challenges to power designers, who must balance system performance with battery life requirements. As second-generation patches use multimodal sensing to improve accuracy and effectiveness, the challenges are further highlighted, and more stringent indicators are imposed on the power supply.

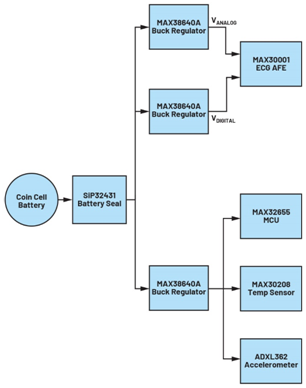

Figure 1. ECG patch power supply schematic. A 235 mAh CR2032 lithium coin cell battery powers the regulator, microcontroller, ECG front end, temperature sensor, and accelerometer.

Take the ECG RPM patch (see Figure 1) for example, which continuously monitors ECG and accelerometer while checking temperature every 15 minutes. Data is transmitted every 2 hours via Bluetooth® Low Energy (BLE), for a total of 12 BLE transmissions per day. The patch supports three different load modes: standard monitoring, temperature monitoring, and transmission mode. In standard monitoring mode, only ECG and accelerometer are monitored. In temperature monitoring mode, another temperature sensor is also monitored. In transmission mode, the BLE radio monitors ECG and accelerometer data simultaneously and transmits the data synchronously.

Designing an RPM, such as an ECG patch, can be challenging for power designers on multiple levels. Designs are often limited by space, and patches with multiple sensors may require multiple power rails. Since RPM patches are typically single-use products, designers often choose a coin cell battery as a cost-effective power source. If only a coin cell battery is used to power the patch, designers must also consider the efficiency of the power subsystem.

Another challenge that power designers often overlook is how to extend the shelf life of their products. Since shutdown current and battery self-discharge will shorten the life of any system, designers must determine whether the RPM patch can meet the operating time requirements after the shelf life, and if not, what measures can be taken to preserve the battery life before the patch reaches the end user.

Insight into battery runtime

In order to accurately understand whether the power solution meets the battery life requirements, the load profile must be determined. The load profile is a simple representation of the system load duty cycle. For remote patient monitoring patches, three different operating modes can be started: standard monitoring, temperature monitoring, and transmission mode.

In standard monitoring mode, the current consumption of the patch shown in Figure 1 (including the 330 nA quiescent current of each buck converter and the current consumption of the MCU) is 1.88 mA. In temperature monitoring mode, the current consumption is 1.95 mA for 200 milliseconds every 15 minutes. In transmission mode, when the patch transmits data over BLE, the current consumption is 7.90 mA for 30 seconds every 2 hours. These values can be found in the active and quiescent current specifications section of the corresponding device data sheet.

To perform a load profile analysis, the duty cycle calculation is determined using the time of day for each operating mode. Using Equation 1:

The duty cycle of the patch can be obtained, as shown in Table 1.

Table 1. Duty cycle of the patch in different working modes

Figure 2. Load curve diagram.

Using the load curve in Figure 2, the current consumption of the patch can be calculated. Taking the effective current consumption in each operating mode, the average current consumption per day can be calculated using Formula 2.

Here is an example calculation:

Current per day in standard monitoring mode = current in standard monitoring mode × duty cycle in standard monitoring mode × 24 hours

Standard Monitor Mode Current = 1.88 mA Standard Monitor Mode Duty Cycle = 0.9956

Current per day in standard monitoring mode = 1.88 mA × 0.9956 × 24 hours = 44.92 mAh/day

Once the daily current consumption for each operating mode is determined, the battery life can be determined using Equation 3.

Here is another calculation example:

Battery capacity = 235 mAh

Current per day in standard monitoring mode = 44.92 mAh/day

Current per day in temperature monitoring mode = 0.01 mAh/day Current per day in transmission mode = 0.79 mAh/day

Battery life (days) = 235 mAh / (44.92 mAh/day + 0.01 mAh/day + 0.79 mA/day) = 5.14 days

These calculations indicate that the device will meet the five-day operating time requirement and have a battery life of more than 5.1 days. However, this result is deceptive because it does not take into account the shelf life of the system. In the medical device industry, it is best to design for a 14-month shelf life (12 months shelf life and two months shipping).

Shelf life factors that must be considered

Adding the shutdown currents of the devices in the system, and using the typical self-discharge rate of 1% to 2% per year for a CR2032 battery, it can be seen that after 14 months, the battery capacity is insufficient to support a five-day operating period and the battery needs to be sealed.

Table 2. Battery capacity after 14 months

After 14 months on the shelf, the battery capacity will have decreased significantly. When the CR2032 sits idle on the shelf, nearly 40% of the energy will be consumed through shutdown current and battery self-leakage. Substituting this battery capacity into Equation 3 gives a more accurate run time:

Battery life (days) = 146.66 mAh/(standard monitoring mode + temperature monitoring mode + transmission mode)

Battery life (days) = 146.66 mAh / (44.92 mAh/day + 0.01 mAh/day + 0.79 mA/day) = 3.21 days

After more than a year on the shelf, battery capacity is affected by battery self-discharge and system shutdown current. Battery self-discharge is related to the battery chemistry and the environment. The chemistry of a CR2032 battery is lithium manganese, and it has a self-discharge rate of 1% to 2% per year. After a year, a button cell battery can lose 2% of its capacity in a dormant state. In contrast, the chemistry of a BR2032 battery is lithium-fluorinated carbon polymer, and it has a self-discharge rate of 0.3% per year. We often think that the battery chemistry that is best suited for an application is the one with the lowest discharge rate, but this is not the case. Although the BR2032 battery has a lower discharge rate, its capacity is also lower than that of a 200 mAh CR2032 battery. Recalculating using the previous formula can determine whether such a low-capacity battery has enough charge.

In this ECG patch, the IC shutdown current is the biggest factor in reducing battery life when the system is powered off. Shutdown currents are drawn when the IC is disabled and there is no active load. These currents are typically due to leakage in the IC and ESD protection devices within the IC, which consume a small amount of current even when there is no load. These currents are typically small (less than 1μA), but have a large impact on battery life. In this RPM patch, the shutdown current can reduce the battery capacity by up to 40% in one year. Using a battery seal limits the system from drawing excessive current from the battery when it is shut down.

Battery sealing is commonly done in two ways: mechanical battery seals in the form of a polyester film pull tab, and electrical battery seals in the form of a load switch. A polyester film/plastic pull tab is a mechanical battery seal where a plastic pull tab is located between the battery and the system. When the device is ready to be used, the user simply pulls out the plastic tab and the battery begins to power the system. This is a simple, low-cost, and proven mechanical battery seal that has been used for many years. However, this solution is not always feasible for medical devices. For ECG patches that need to be waterproof, the protruding groove of the polyester film makes the patch susceptible to water damage. In addition, this small plastic tab may not be easy to use for end users who are not dexterous.

A simple load switch, such as the Vishay SiP32341, is a good choice for an electrical battery seal. This device is a field effect transistor that, when turned on, isolates the battery from the rest of the system, making the shutdown current of the SiP32341 the only current draw on the battery. The load switch has a logic control line that can be turned on by a push button when the device is ready to be used. The shutdown current of the SiP32341 is typically 14 pA, which is a significant improvement over the current draw of the entire system without a battery seal. If the SiP32341 is used as a battery seal, the original CR2032 battery retains 99.97% of its capacity over 14 months. Without a battery seal to protect the battery from the shutdown current of the ECG patch, the original CR2032 battery retains only 62.39% of its original charge. Once this 37% capacity difference is eliminated, the ECG patch can still meet the 5-day life requirement after the 14-month shelf life.

Previous article:Nidec's electric vehicle drive hub motor is adopted by Yadea's "Battery-Swapping Beast 01"

Next article:How to design a low-power, high-precision bicycle power meter

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- CGD and Qorvo to jointly revolutionize motor control solutions

- CGD and Qorvo to jointly revolutionize motor control solutions

- Keysight Technologies FieldFox handheld analyzer with VDI spread spectrum module to achieve millimeter wave analysis function

- Infineon's PASCO2V15 XENSIV PAS CO2 5V Sensor Now Available at Mouser for Accurate CO2 Level Measurement

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- A new chapter in Great Wall Motors R&D: solid-state battery technology leads the future

- Naxin Micro provides full-scenario GaN driver IC solutions

- Interpreting Huawei’s new solid-state battery patent, will it challenge CATL in 2030?

- Are pure electric/plug-in hybrid vehicles going crazy? A Chinese company has launched the world's first -40℃ dischargeable hybrid battery that is not afraid of cold

- PCB package design of electronic devices

- 【RT-Thread Reading Notes】9. RT-Thread Study Chapters 14-16 Reading Notes

- Why are there Flash and EEPROM in microcontrollers?

- MCU solves RFID smart tag/smart card system design problems

- TI official website millimeter wave radar application demonstration

- Looking for a displacement sensor, impact sensor, acceleration sensor and GPS kit to assemble into a system

- Industrial Automation Equipment Recruitment

- Use familiar methods to quickly realize every idea! Gizwits Gokit3 free trial

- Full-wave rectifier waveform problem

- DSPC6678 on-chip storage space allocation mechanism

LM124J/NOPB

LM124J/NOPB

京公网安备 11010802033920号

京公网安备 11010802033920号