LED street lights are low-voltage, high-current driving devices. The intensity of their light is determined by the current flowing through the LED. Too strong a current will cause the LED to attenuate, and too weak a current will affect the LED's light intensity. Therefore, the LED driver needs to provide a constant current power supply to ensure the safety of high-power LED use and achieve the ideal light intensity. Using AC power to drive high-power LEDs requires solving the problems of step-down, isolation, PFC (power factor correction) and constant current. It also requires relatively high conversion efficiency, a small size, long-term operation, easy heat dissipation, low cost, anti-electromagnetic interference, and over-temperature, over-current, short-circuit, open-circuit protection, etc. The PFC switching power supply designed in this scheme has good performance, is reliable, economical and efficient, and achieves satisfactory results in the use of LED street lights.

1 System Structure Diagram

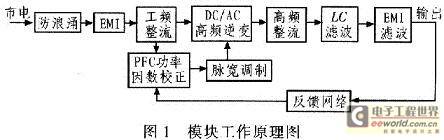

The switching power supply realized by isolation transformer and PFC control outputs constant voltage and constant current to drive LED street lamps. The overall block diagram of the circuit is shown in Figure 1.

LEDs have poor surge resistance, especially reverse voltage resistance. It is also important to strengthen this protection. LED street lights installed outdoors need to strengthen surge protection. Due to the start-up of the grid load and the induction of lightning strikes, various surges will invade from the grid system, and some surges will cause damage to the LED. Therefore, the LED driver power supply should have the ability to suppress surge intrusion and protect the LED from damage. The EMI filter circuit mainly prevents the harmonic interference on the grid from entering the module and affecting the normal operation of the control circuit.

The three-phase AC power is converted into pulsating DC power after full-bridge rectification. Under the action of filter capacitors and inductors, DC voltage is output. The main switch DC/AC circuit converts DC power into high-frequency pulse voltage and outputs it at the secondary of the transformer. The high-frequency pulse output by the transformer is rectified, LC filtered and EMI filtered to output the DC power required by LED street lights.

The PWM control circuit uses voltage and current dual loop control to adjust the output voltage and limit the output current. The feedback network uses the constant current and constant voltage device TSM101 and comparator, and the feedback signal is sent to the PFC device L6561 through an optical coupler. Due to the use of PFC devices, the power factor of the module reaches 0.95.

2 DC/DC Converter

There are many types of DC/DC converters. In order to ensure the safety of electricity use, this design scheme chooses isolated type. Isolated DC/DC conversion can be further subdivided into forward type, flyback type, half-bridge type, full-bridge type and push-pull type. Among them, half-bridge type, full-bridge type and push-pull type are usually used in high-power output occasions. Their excitation circuits are complex and difficult to implement; while forward and flyback circuits are simple and easy, but because the flyback type is more adaptable to the situation where the input voltage changes than the forward type, and the PFC output voltage in this power supply system will change greatly, the DC/DC conversion adopts the flyback method, which is conducive to ensuring that the output voltage is stable and unchanged.

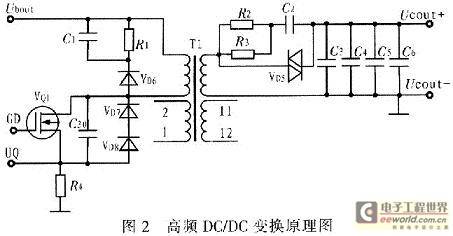

The flyback switching power supply is mainly used in situations where the output power is 5~150W. This power supply structure is derived from the Buck-Boost structure and an isolation transformer is added, as shown in Figure 2. In the flyback topology, the transformer is used as an energy storage element. When the switch tube is turned on, the transformer stores energy and the load current is provided by the output filter capacitor; when the switch tube is turned off, the transformer transfers the stored energy to the load and the output filter capacitor to compensate for the energy consumed when the capacitor alone provides the load current.

In the figure, T1 is a high-frequency isolation transformer, VQ1 is a CMOS power transistor 17N80C3, VD7 and VD8 are transient suppression diodes, VD6 is a fast recovery diode, VD5 is a dual diode, and C3, C4, C5 and C6 are electrolytic capacitors. Ubout is a pulsating DC signal from the rectifier bridge, and GD is a control signal from the power factor correction circuit. The leads 1 and 2 of the transformer form a winding to provide working power to the PFC device, and the leads 11 and 12 form a winding to provide working power to the constant current and constant voltage device and the comparator.

3 Feedback Network Circuit

3.1 Constant current and constant voltage circuit

This design uses the constant current and constant voltage control device TSM101 to adjust the output voltage and current to make it stable. The circuit is shown in Figure 3. Through the control of TSM101, the constant current (CC) and constant voltage (CV) operation of the power supply are guaranteed. In Figure 3, Uout+ and Uout- are the voltages filtered by the isolation transformer through dual diodes and electrolytic capacitors, and then the outputs after filtering by inductor L4 and capacitor are Uout+ and Uout-, which are the output voltages of this power module and are directly added to the LED street lamp. Adjustable resistors RV1 and RV2 adjust the output voltage and current respectively. R10 and R11 are 22mΩ resistors, which sample the voltage and current output of the power supply respectively. The output TOUT of TMS101 is sent to pin 5 of L6561 through circuits such as optocouplers, thyristors and triodes, and constant current control is achieved through the feedback circuit. Device pin 8 is connected to the auxiliary power supply, and pin 4 is connected to the secondary ground of transformer T1.

3.2 Comparator Circuit

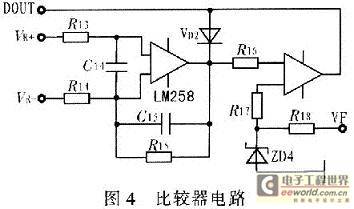

3.2 Comparator CircuitThe comparator LM258 is used, and the circuit is shown in Figure 4.

The voltage signals VR+ and VR- at both ends of the sampling resistor at the output end are sent to the comparator LM258, which is compared with the preset voltage to generate a voltage feedback signal DOUT. VF is the auxiliary power generated by the secondary winding of the transformer T1.

4 PFC circuit

This design uses the most common active power factor correction control device L6561. The working principle of the PFC circuit is shown in Figure 5.

Pin 8 of L6561 is the power input terminal, which is provided by the secondary winding of transformer T1; Pin 7 is the drive signal output pin, which directly drives the MOS tube VQ1; Pin 6 is the reference ground, which is connected to the ground of the main circuit; Pin 5 is the zero-crossing detection pin, which is used to determine when to turn on the MOS tube. The winding composed of pins 1 and 2 of transformer T1 transmits the inductor current zero-crossing signal to pin 5 of the device through a resistor, and the signal DOUT generated by the comparator LM258 is transmitted to pin 5 of the device through an optocoupler, a transistor, a thyristor, etc. to detect the output current. Pin 4 is the MOS tube current adopting pin. The device compares the signal detected by this pin with the inductor current signal generated inside the device to determine when to turn off the MOS tube. In Figure 2, resistor R4 is used as a current detection resistor to sample the MOS tube current. One end of the resistor is connected to the system ground, and the other end is connected to the source of the MOS tube and pin 4 of the device. Pin 3 is an input end of the device's internal multiplier. This pin is connected to the output voltage of the rectifier bridge circuit to determine the waveform and phase of the input voltage to generate the inductor current reference signal inside the device. In Figure 5, Ubout is transmitted to pin 3 after being divided by 3 resistors. Pin 2 is another input end of the internal multiplier and the output end of the voltage error amplifier. Pin 1 is the input end of the system feedback voltage. The output TOUT of the constant current and constant voltage device transmits the voltage feedback to pin 1 of the device through an optocoupler to form a negative feedback loop for the output voltage. Resistor R28 and capacitor C18 are connected between pins 1 and 2 of the device to form a compensation network for the voltage loop.

5 Test Results

After the power module is installed, a load is added and the key points are tested with an oscilloscope. Figure 6(a) shows the output voltage Ubrout+ of the rectifier bridge, Figure 6(b) shows the waveform of the voltage Ubout+ after Ubrout+ flows through the inductor, and Figure 6(c) shows the waveform of the output voltage Ucout+ of the dual diode.

6 Conclusion

This solution adopts an outdoor LED street light power supply with active PFC functional circuit design, built-in complete EMC circuit and efficient lightning protection circuit, which meets the requirements of safety regulations and electromagnetic compatibility. It adopts voltage loop feedback, voltage limiting constant current, high efficiency, accurate constant current, wide range, and realizes wide input, voltage stabilization constant current output, avoiding the change of LED forward voltage and causing current change. At the same time, the constant current stabilizes the brightness of the LED. The whole machine has fewer components and a simple circuit. The power is 90W and the power factor is 0.95. According to user needs, LED temperature negative feedback can be added to the constant current output to prevent the LED temperature from being too high.

Previous article:Combination of linear and switching LED power supply design

Next article:Four protection circuit designs for LED power supply

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Why software-defined vehicles transform cars from tools into living spaces

- How Lucid is overtaking Tesla with smaller motors

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Wi-Fi 8 specification is on the way: 2.4/5/6GHz triple-band operation

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Vietnam's chip packaging and testing business is growing, and supply-side fragmentation is splitting the market

- Three steps to govern hybrid multicloud environments

- Three steps to govern hybrid multicloud environments

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- Microchip Accelerates Real-Time Edge AI Deployment with NVIDIA Holoscan Platform

- Technical Articles | Frontline engineers explain to you: Tips for testing the dark current of passive device PD

- BSL source code for DM642EVM

- Teachers, what kind of amplifier should be used to amplify the mv level of this sensor?

- A record of the development experience of a new embedded CPU chip CC2540

- if(Data==1)start=1; Why is there no space after if and before start in this sentence? This will not cause errors during compilation.

- Xiaomi Robot Vacuum Cleaner Features and Chip Parameters

- [Raspberry Pi 4B Review] Raspberry Pi 4 pin functions and operation methods

- Live: Embedded to Cloud Journey with PIC and AVR MCUs from the Microchip Ecosystem Part 2

- Purgatory Legend-RAM War

- [CY8CKIT-149 PSoC 4100S Review] + Familiar with the development environment

LD149

LD149

京公网安备 11010802033920号

京公网安备 11010802033920号