In recent years, with the development of solar photovoltaic power generation technology and LED lighting technology, solar LED street lights have entered the field of urban lighting. Compared with traditional lighting sources, LED as a lighting source has the advantages of DC low voltage drive , low power consumption, vibration resistance, long life, nanosecond response speed, large design space, environmental protection, continuous switching , and easy 0-100% dimming function. It is considered to be a new generation of green lighting equipment. Solar LED street lights use solar energy as energy. Each street light is independent and easy to install. There is no need to lay cables and wires, no AC power and electricity charges. It uses DC power supply and light control timing control. It is safe, reliable, energy-saving, economical, environmentally friendly and practical.

1. Selection of solar cell panels and batteries

1.1 Solar Panel Selection

At present, the photoelectric conversion efficiency of monocrystalline silicon solar cells is about 15%, and the highest is 24%. It is the highest photoelectric conversion efficiency among all types of solar cells, and the technology is the most mature. The service life can generally reach 15 years, and the highest can reach 25 years. The photoelectric conversion efficiency of polycrystalline silicon solar cells is much lower than that of monocrystalline silicon solar cells, and its photoelectric conversion efficiency is about 12%. At the same time, the service life of polycrystalline silicon solar cells is also shorter than that of monocrystalline silicon solar cells. The photoelectric conversion efficiency of amorphous silicon thin-film solar cells is relatively low. The current international advanced level is about 10%, and it is not stable enough. As time goes by, its conversion efficiency decays, which directly affects its practical application. Therefore, monocrystalline silicon solar cells are currently used more.

According to the principle of solar radiation, the amount of radiation received by the solar cell array surface is related to many factors: the local latitude, altitude, the degree of atmospheric pollution or transparency, the change of the four seasons in a year, the change of the time of day, the value of solar radiation reaching the ground , the proportion of scattered components, the reflection coefficient of the ground surface, the operation mode of the solar cell array or the change of the inclination angle of the fixed array, and the cleanliness of the solar cell array surface. The charging and discharging efficiency of the solar lighting system is 0.75, the solar cell module group loss correction coefficient is 0.95, and the dust shielding and other loss correction coefficient is 0.90. After consulting the data, converting the units and simplifying the processing, the calculation formula of the total amount of solar cells P can be obtained:

1.2 Battery selection

The capacity of the battery should be determined according to the power of the solar panel and the power of the LED street light and the lighting time. The battery should match the solar cell and LED street light . A simple method can be used to determine the relationship between them. The solar cell power must be more than 4 times higher than the load power for the system to work properly. The voltage of the solar cell must exceed the working voltage of the battery by 20% to 30% to ensure normal storage of the battery. Therefore, the battery capacity must be more than 6 times higher than the daily consumption of the load.

The calculation formula of battery capacity Bc is:

Bc=(PL×10×D)/(Kb•V)

In the formula, PL is the average daily power consumption, D is the number of rainy days, Kb is the safety factor, 1.1~1.4 (including the temperature correction factor To=1 above 0℃, 1.1 above -10℃, 1.2 below -10℃, discharge depth cc=0.75), and V is the operating voltage.

According to formula (2), the capacity of the battery can be estimated. At the same time, the charging efficiency of the battery depends on the charging method. According to the system requirements and the verification of various indicators, a 12 V 100 Ah valve-regulated sealed lead-acid battery is selected here.

2. Solar controller Hardware design

The full name of solar controller is solar charge and discharge controller . It is an automatic control device that controls the solar cell array to charge the battery and the battery to supply power to the load. It can automatically prevent the battery from overcharging and over-discharging. It regulates and controls the charging and discharging conditions of the battery, and controls the power output of the solar cell module and the battery to the load according to the load's power supply demand. It is the core control part of the entire system.

The charging controller designed in this paper uses ATmega128 microcontroller as the main control device, detects the output voltage of the solar panel, selects the appropriate DC/DC branch, detects the voltage value of the battery, and selects the appropriate charging method according to the charge state of the battery to provide overcharge and over-discharge protection for the battery.

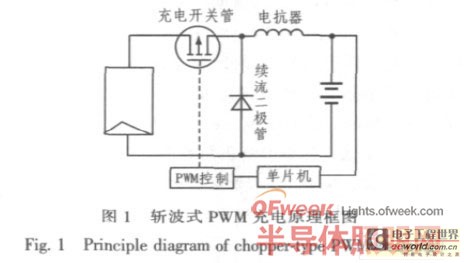

Figure 1 is a schematic diagram of chopper PWM charging. The battery charging terminal voltage is detected and compared with the given point voltage. If the battery voltage is less than the given voltage, the chopper is fully turned on to quickly charge the battery. If it is greater than the given voltage, the duty cycle of the power tube is adjusted according to the ratio, and the charging enters the slow charging stage to improve the charging characteristics, and finally enters the trickle charging stage to prevent overcharging.

Chopper PWM charging principle diagram

The AVR128 microcontroller (PB4) gives a charging control signal, that is, PB4=1, the NPN type 0805 transistor is turned on, and the collector is grounded, so that the gate-source voltage of IRF4905 is clamped at -10 V, the IRF4905 tube is turned on, and the solar panel charges the battery; conversely, the NPN type 0805 transistor is cut off VGS=0 V , the IRF4905 tube is disconnected, and the solar panel cannot charge the battery.

ATmega128 has a built-in 10-bit successive approximation A/D converter. The A/D converter is connected to an 8-channel analog multiplexer to sample the 8-way single-ended input voltage of port F. The positive electrode of the battery is connected to the PF1 pin of the microcontroller. When the voltage drops to 10 V, the microcontroller automatically detects it and takes corresponding action, as shown in Figure 2.

System hardware circuit

3. LED selection

LEDs are classified according to the input power of current market products. Those with an input power of tens of mW are called traditional low-power chips; those with an input power of less than 1 W are power LEDs; and those with an input power equal to or greater than 1 W are W-class power (high-power) LEDs. Currently, the most common high-power products are 1, 3, 5, 8, and 10 W. 1 W and 3 W LEDs have been mass-produced and are developing in the direction of high current (300 mA to 1.4 A), high efficiency (60 to 1,204 lm/W), and adjustable brightness [3]. High-power LED street lamps use a single LED with a power greater than 1 W. 3 W LEDs from CREE of the United States are selected. Multiple chips are integrated on a printed circuit board and arranged in a dot matrix with a certain spacing as a planar light source. They are combined into a single high-power LED module and installed in street lamps to increase the chip area and the amount of light emitted.

When designing road lighting by combining multiple LEDs together, in addition to sufficient luminous flux and reasonable optics design to ensure reasonable light distribution, the more important issue is heat dissipation. Since street lamps are used outdoors at night, the heat dissipation surface is located on the side and the body is less restricted, it is conducive to natural convection heat dissipation. Therefore, LED street lamps choose natural convection heat dissipation. At the same time, the whole lamp uses high thermal conductivity aluminum as the heat dissipation body, which solves the heat dissipation problem of LEDs.

4. LED combination and driving method

There are three commonly used LED combinations: parallel, series and mixed.

1) The parallel connection method requires the LED driver to output a larger current and a lower load voltage. The voltage distributed across all LEDs is the same. When the consistency of the LEDs varies greatly, the current passing through each LED is inconsistent, and its brightness is also different.

2) The series connection requires the LED driver to output a higher voltage. When the consistency of the LEDs varies greatly, the voltages distributed across different LEDs are different, the current passing through each LED is the same, and the basic brightness of the LEDs is consistent.

3) When more LEDs are needed, if all LEDs are connected in series, the LED driver will need to output a higher voltage; if all LEDs are connected in parallel, the LED driver will need to output a larger current. Connecting all LEDs in series or in parallel not only limits the amount of LEDs used, but also increases the load current of parallel LEDs, and the cost of the driver will also increase significantly. In the parallel connection method, the number of LEDs is evenly distributed, the voltage distributed on a string of LEDs is the same, the current passing through each LED in the same string is basically the same, and the LED brightness is consistent. At the same time, the current passing through each string of LEDs is also similar.

Through the above analysis, high-power LEDs are used in the field of lighting. Since the current and voltage parameters of LEDs have typical PN junction volt-ampere characteristics, a small change in its forward voltage drop will cause a large change in forward current. Unstable working current will affect the life and light decay of LEDs. Therefore, the brightness of high-power LEDs is completely controlled by current, and the drive circuit must provide a constant current.

In the driving circuit, a high-power LED driver XLT* is selected to drive the LED. XLT* is a PWM high-efficiency LED driver controller designed using BIC MOS technology. It can effectively drive high-brightness LEDs within the input voltage range of 7 to 450 VDC. The driver can drive the external MOSFET at a fixed frequency of up to 300 kHz, and its frequency can be programmed by an external resistor. The external high-brightness LED string can be controlled by a constant current method to maintain constant brightness and enhance the reliability of the LED. Its constant current value is determined by the value of the external sampling resistor and varies from a few mA to 1 A. The LED driven by XLT* can adjust the brightness linearly through an external control voltage, or adjust the brightness of the LED string through an external low-frequency PWM method. Therefore, according to the actual needs of the solar LED street light design, the LED hybrid method is selected, and the XLT* driver is selected to design the drive circuit to drive the LED, as shown in Figure 3.

XLT604 Functional Block Diagram

The main functions of each pin of XLT* are: LD is the linear input dimming terminal; ROSC is the oscillation resistor access segment; CS is the LED current sampling input terminal; GND is the chip ground; GATE is the gate driver of the external MOSFET; VDD is the chip power supply; PWM is the PWM input dimming terminal, which also serves as the enable terminal.

5. Solar 30 W LED street light system design

The total annual sunshine hours in Taiyuan are 2,360 to 2,796 h. The total annual solar radiation is 5,442.8 to 5,652.18 MJ/m2, and the peak sunshine hours are 4.832,053 2, which is a high-irradiance category in the country. Therefore, Taiyuan has good conditions for solar energy utilization. The following is an example of a 30 W LED street light system in Taiyuan:

1) Determine the local meteorological and geographical conditions. After searching the data, Taiyuan area: Latitude: 37°27′~38°25′N, Longitude: 111°30′~113°09′E, Altitude: 800 m, Longest rainy day: 7 days

2) Determination of daily load consumption The power of the street lamp is 30 W and the continuous working time is 10 hours per day. Therefore, the daily power consumption is

QL=30w×10h=300Wh (3)

3) Determination of the inclination angle: The inclination angle in Taiyuan area is 38°. The optimal inclination angle of the solar panel is: 38°+5°=43°. Therefore, the solar panel faces due south.

4) Calculation of the total energy of solar cells Through data query, we know that Kop=1.1 in Taiyuan area. From the local latitude, longitude, altitude, and data released by the local meteorological department: the average daily solar radiation in Taiyuan area is 15MJ/(m^2•d) , so the annual average daily radiation on the horizontal plane HL=15,000KJ/(m^2•d) .

P=5 618×A×QL/(Kop×HL)=112Wp

The parameters of the solar cell components are as follows: operating voltage is 17.2 V, operating current is 3.49 A, open circuit voltage is 21.6 V, short circuit current is 3.9 A, and peak power is 60 Wp. A solar cell panel with a peak power of 60 Wp is selected, and a total of 2 solar cell components are used. The solar cell is designed to be charged by a 12 V battery.

5) Calculation of battery capacity Bc The battery capacity Bc can be calculated using formula (5):

Bc=(30 W×10×7)/(1. 1×12)=159 Ah (5)

Therefore, two groups of 12 V 100 Ah valve-regulated sealed lead-acid batteries can be used.

At present, high-power LED street lights basically use white light with a color temperature of about 5,000 K. As a road lighting source, the visual sense is too cold, and the observation ability will decrease when looking far away. The warm white light of about 3,000 K is more suitable for road lighting. At the same time, the wind resistance design of the battery component bracket and the wind resistance design of the lamp pole should also be considered. The working voltage of LED street lights is generally 12 V or 24 V, which is a safe voltage and does not require electrical protection grounding. However, the metal lamp pole of the LED street light should be grounded for lightning protection, and the grounding resistance should not be greater than 10 Ω.

6. Conclusion

Solar LED street lighting system is a perfect combination of natural energy solar energy and environmentally friendly light source LED, and its development prospects are extremely broad. However, there are still many problems in the actual application of solar LED street lighting. Including: 1) the problem of centralized management; 2) the life of solar cells, batteries and other control components is often lower than the life of LED; 3) the weight of solar cells installed at a relatively high height generally leads to the problem of improving the windproof ability of the light pole design. These problems are all solar LED street lighting that need to be further solved.

Previous article:In-depth analysis of LED high-power driver and its application products

Next article:LED packaging must be designed in a reasonable way to be put into use

Recommended ReadingLatest update time:2024-11-16 16:37

- Popular Resources

- Popular amplifiers

-

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工)

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工) -

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun)

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun) -

Intelligent Control Technology of Permanent Magnet Synchronous Motor (Written by Wang Jun)

Intelligent Control Technology of Permanent Magnet Synchronous Motor (Written by Wang Jun) -

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

100 Examples of Microcontroller C Language Applications (with CD-ROM, 3rd Edition) (Wang Huiliang, Wang Dongfeng, Dong Guanqiang)

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Force control modbus communication method modbus-tcp, modbus-rtu Modicon communication configuration steps

- Do you know the future development trend of WiFi?

- ST's sensors can be purchased at the STM32 Tmall official flagship store

- "Dating in Spring" + "Just Strolling"

- How to build a Keil project using the LPC8xx ROM?

- C2000 CLA FAQ: Architecture and Configuration

- Divide an assembly file into several assembly files. Compile prompt variable is not defined

- RF amplifier performance test

- What kind of feedback is introduced in the following circuit?

- Storage time of different surface treatment processes for circuit boards

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工)

西门子S7-12001500 PLC SCL语言编程从入门到精通 (北岛李工)

京公网安备 11010802033920号

京公网安备 11010802033920号