The basic test scheme for integrated capacitors is to connect the integrated capacitor to a Q meter (with an inductor). Adjust the "capacitance" knob on the Q meter, and use the resonance characteristics of the second-order circuit until the Q displayed on the Q meter reaches the maximum. Record the adjusted capacitance value, and compare this capacitance value with the nominal value to obtain the test result (verification result). Its principle circuit is shown in Figure 1. The output voltage is taken from the resistor, so the voltage transfer function is:

The ratio of the center frequency to the passband is the quality factor, denoted as Q, that is

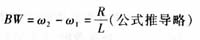

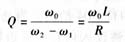

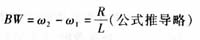

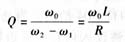

,

,

the theoretical idea of this design is: the input sine wave amplitude is fixed and the frequency is changed. When the input frequency is ω0, the voltage across the resistor R is the maximum. The test can be made by comparing the frequency at the maximum output waveform voltage with the theoretical ω0.

Keywords:VEE

Reference address:Integrated Capacitor Automatic Test System Based on VEE

The ratio of the center frequency to the passband is the quality factor, denoted as Q, that is

,

, the theoretical idea of this design is: the input sine wave amplitude is fixed and the frequency is changed. When the input frequency is ω0, the voltage across the resistor R is the maximum. The test can be made by comparing the frequency at the maximum output waveform voltage with the theoretical ω0.

Three instruments are used in this design, namely HP's HP54602B oscilloscope, HP's HP33120A function generator/arbitrary waveform signal generator, and Fluke's 8840A multimeter. These instruments all have a general purpose interface bus (GP IB). Each instrument has a unique GPIB address in the automatic test system. The computer used is equipped with a GPIB interface card. It is connected to various instruments through the bus to form an automatic test system. The PC programs and controls the test instrument through the interface; through multiple GPIB interface cards, close-range high-speed parallel data communication between microcomputers is realized.

2.1IEEE-488 (GP-IB) interface

Most modern intelligent instruments have two working modes: local (local) and remote (remote). In the local working mode, the user issues various commands to the instrument through the keyboard to instruct the instrument to complete various actions. In the remote working mode, the controller (usually a computer) issues various commands to the instrument through the GP-IB interface bus. The interface is a key component for intelligent instruments to communicate with the outside world. The GPIB interface bus has 16 signal lines: 8 DIO data lines, used to transmit various multi-line messages; 3 hook lines, used to ensure reliable transmission of information; 5 interface management lines, used to manage the working mode of the interface.

2.2 Agilent VEE software

Agilent's VEE software (Visual Engineering Environment) is a graphical programming language for instrument control, supporting multiple working platforms such as MS Windows, HP UNIX workstations and Sun SPARC workstations, and is also one of the main software development environments for VXI bus test systems. It is a modular flowchart programming language, which uses data lines and control lines to connect various modules together to form the entire program.

2.1IEEE-488 (GP-IB) interface

Most modern intelligent instruments have two working modes: local (local) and remote (remote). In the local working mode, the user issues various commands to the instrument through the keyboard to instruct the instrument to complete various actions. In the remote working mode, the controller (usually a computer) issues various commands to the instrument through the GP-IB interface bus. The interface is a key component for intelligent instruments to communicate with the outside world. The GPIB interface bus has 16 signal lines: 8 DIO data lines, used to transmit various multi-line messages; 3 hook lines, used to ensure reliable transmission of information; 5 interface management lines, used to manage the working mode of the interface.

2.2 Agilent VEE software

Agilent's VEE software (Visual Engineering Environment) is a graphical programming language for instrument control, supporting multiple working platforms such as MS Windows, HP UNIX workstations and Sun SPARC workstations, and is also one of the main software development environments for VXI bus test systems. It is a modular flowchart programming language, which uses data lines and control lines to connect various modules together to form the entire program.

The following is the VEE test program (see Figure 3). All results are generated by VEE simulation. The program generates a frequency sweep process by VEE (see Figure 4), and then the multimeter randomly generates a voltage value at each frequency (see Figure 6), and outputs the maximum value after comparison. This series of processes are set by the main program, and the output operator interface is shown in Figure 5.

Since all kinds of instruments used in the test system conform to the instrument standards based on IEEE 488 (GPIB) bus, it provides great convenience for system integration. And thanks to Agilent VEE virtual instrument software technology, the system has greater programming convenience, versatility and flexibility in computer-aided measurement of component parameters. On this powerful and convenient virtual instrument development platform, it is more intelligent, more reliable and more operable than traditional test instruments.

Previous article:Digital Multimeter as Cable Checker

Next article:Application of DDE between PLC and Excel in Measurement and Control System

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- Huawei's Strategic Department Director Gai Gang: The cumulative installed base of open source Euler operating system exceeds 10 million sets

- Download from the Internet--ARM Getting Started Notes

- Learn ARM development(22)

- Learn ARM development(21)

- Learn ARM development(20)

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

Guess you like

- Car central control 12V power supply filtering

- 【IoT Development】D3 engine has been upgraded! Come and experience the new version of Gizwits Intelligent Scene Push

- 02_Use Quartus II Timequest timing analyzer to constrain and analyze the design

- Serial port automatic transceiver chip

- Why does the amplitude of AD835 increase when the same frequency input is above 15M? How can I make the amplitude-frequency curve flatter?

- Today at 10:00 AM Award-winning live broadcast: Azure Sphere helps to provide stable, secure and flexible IoT solutions

- The role of capacitors

- I need help with a semiconductor-related book "Photolithography near the diffraction limit"

- New hot spot in automobiles: In-depth analysis of T-BOX system solutions

- What are the differences between 4G and 5G networks?

5962R8773901VDA

5962R8773901VDA

京公网安备 11010802033920号

京公网安备 11010802033920号