Challenge: Develop a milk refrigeration system for rural areas in India where electricity supply is not guaranteed.

Solution: A refrigeration system that uses solar energy in combination with available grid electricity by converting and storing thermal energy and releasing it when freezing the milk.

Figure 1. Solar photovoltaic array powers the refrigeration system in the blue roof building

Figure 2. Simple operation interface designed for dairy farmers

Figure 3. The LabVIEW system periodically publishes operating data to the Twitter page

Figure 4. Dynamic load balancing using LabVIEW Real-Time and FPGA

programming Author: Sorin Grama - Promethean Power Systems, USATo

address the lack of cold chain infrastructure for transporting fresh food in India, Promethean Power Systems recently developed a refrigeration system that successfully addresses a number of unique challenges facing the Indian dairy industry. The source of milk supply in India is scattered across numerous small farms in the vast rural areas. The current milk collection process is very inefficient, mainly relying on twice-daily hot milk collection, resulting in high transportation costs and frequent milk spoilage—up to 30% in the hot season. If dairy companies can quickly cool raw milk at rural collection centers, transportation costs can be reduced by half, milk spoilage problems can be avoided, and dairy farmers can earn more income. Dedicated milk refrigeration equipment is already available on the market, but rural areas have unstable power supply. If this solution is adopted, it will need to use diesel generators to power these equipment, which will undoubtedly increase investment and operating costs and is not a good solution.

Based on these investigations, we set out to design a milk refrigeration system that is more suitable for remote rural areas. Because we had expertise and technology in leading solar installations and solar was widely considered a viable and economical energy source for sunny regions such as India, we designed the system based on solar energy. However, because the milk cooling system was particularly important and had to operate 24/7/365, we combined solar energy with available grid power to create a more perfect system that could operate even during long periods of cloudy weather or grid outages (Figure 1). A key part of the system

design was the control system that managed the distribution of power from the two sources (solar and grid) to the loads. The load is typically a cold water tank that uses a refrigeration compressor to convert electrical energy into refrigeration work and store thermal energy. This cold water is then used to cool the milk when it is collected in the morning and evening. In addition, a small battery load system was used to ensure that the control system and refrigeration pumps operated when there was no solar or grid power.

We realized that we needed to design an embedded control system to run the complex algorithms while providing a simple operator interface for the dairy farmers. Therefore, we decided to use the NI Single-Board RIO platform and LabVIEW Real-Time Module as our development system.

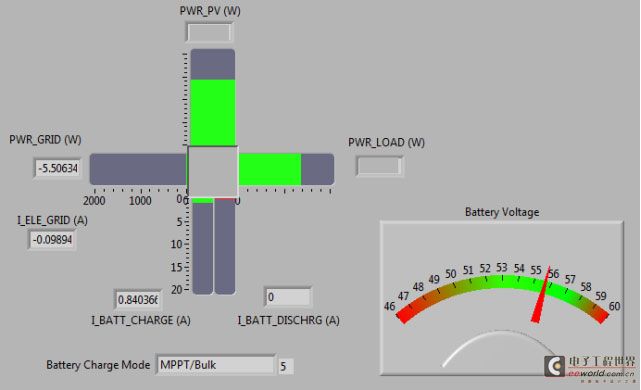

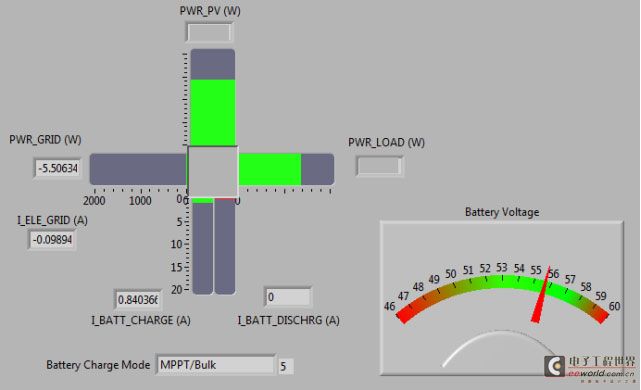

Behind the simple operator interface (Figure 2) is a complex system that combines LabVIEW software and NI hardware to control the operation of the milk refrigeration system and collect valuable data for subsequent engineering analysis and design improvements. The system inputs include temperature, current, and flow sensors , and the outputs are digital control signals, most of which are generated by programming the built-in FPGA hardware of the reconfigurable I/O (RIO) platform.

The control software includes multiple different and independent proportional-integral-derivative (PID) control loops running in parallel to control the system temperature to maintain the critical temperature point of the system. In addition, the embedded software collects and stores data for subsequent analysis. A feature of this system is that it uses mobile phone communication - usually the only communication method in remote areas - to publish summary data of operation in conjunction with a simple text communication protocol and a dedicated Twitter account (Figure 3).

An important aspect of the system is the dynamic load balancing algorithm. The algorithm regulates the system to operate in a solar-powered, grid-powered, or solar-powered and grid-powered mode (Figure 4). Dynamic load balancing is achieved by using the FPGA platform to program itself and use PWM signals to control the power flow to the refrigeration compressor.

The system becomes more complex due to the addition of batteries. The battery plays a dual role as a load and a source of power in the system. A control algorithm was designed to determine when the battery needs to be charged and when the battery is the source of power for the system. Careful design of the battery control ensures that the battery pack is always charged efficiently.

Conclusion

Using the LabVIEW Real-Time Module and the NI Single-Board RIO platform, we designed and built a field test prototype system that runs complex control algorithms and collects valuable engineering data while being easy to operate and debug. The system is now operating in a remote area in southern India, cooling milk every day. As we move toward mass production and commercialization, the data collected from this prototype will be used to improve the system and simplify the design.

Keywords:LabVIEW NI Single-Board RIO

Reference address:Developing a Solar-Powered Milk Refrigeration System Using LabVIEW and NI Single-Board RIO

Solution: A refrigeration system that uses solar energy in combination with available grid electricity by converting and storing thermal energy and releasing it when freezing the milk.

Figure 1. Solar photovoltaic array powers the refrigeration system in the blue roof building

Figure 2. Simple operation interface designed for dairy farmers

Figure 3. The LabVIEW system periodically publishes operating data to the Twitter page

Figure 4. Dynamic load balancing using LabVIEW Real-Time and FPGA

programming Author: Sorin Grama - Promethean Power Systems, USATo

address the lack of cold chain infrastructure for transporting fresh food in India, Promethean Power Systems recently developed a refrigeration system that successfully addresses a number of unique challenges facing the Indian dairy industry. The source of milk supply in India is scattered across numerous small farms in the vast rural areas. The current milk collection process is very inefficient, mainly relying on twice-daily hot milk collection, resulting in high transportation costs and frequent milk spoilage—up to 30% in the hot season. If dairy companies can quickly cool raw milk at rural collection centers, transportation costs can be reduced by half, milk spoilage problems can be avoided, and dairy farmers can earn more income. Dedicated milk refrigeration equipment is already available on the market, but rural areas have unstable power supply. If this solution is adopted, it will need to use diesel generators to power these equipment, which will undoubtedly increase investment and operating costs and is not a good solution.

Based on these investigations, we set out to design a milk refrigeration system that is more suitable for remote rural areas. Because we had expertise and technology in leading solar installations and solar was widely considered a viable and economical energy source for sunny regions such as India, we designed the system based on solar energy. However, because the milk cooling system was particularly important and had to operate 24/7/365, we combined solar energy with available grid power to create a more perfect system that could operate even during long periods of cloudy weather or grid outages (Figure 1). A key part of the system

design was the control system that managed the distribution of power from the two sources (solar and grid) to the loads. The load is typically a cold water tank that uses a refrigeration compressor to convert electrical energy into refrigeration work and store thermal energy. This cold water is then used to cool the milk when it is collected in the morning and evening. In addition, a small battery load system was used to ensure that the control system and refrigeration pumps operated when there was no solar or grid power.

We realized that we needed to design an embedded control system to run the complex algorithms while providing a simple operator interface for the dairy farmers. Therefore, we decided to use the NI Single-Board RIO platform and LabVIEW Real-Time Module as our development system.

Behind the simple operator interface (Figure 2) is a complex system that combines LabVIEW software and NI hardware to control the operation of the milk refrigeration system and collect valuable data for subsequent engineering analysis and design improvements. The system inputs include temperature, current, and flow sensors , and the outputs are digital control signals, most of which are generated by programming the built-in FPGA hardware of the reconfigurable I/O (RIO) platform.

The control software includes multiple different and independent proportional-integral-derivative (PID) control loops running in parallel to control the system temperature to maintain the critical temperature point of the system. In addition, the embedded software collects and stores data for subsequent analysis. A feature of this system is that it uses mobile phone communication - usually the only communication method in remote areas - to publish summary data of operation in conjunction with a simple text communication protocol and a dedicated Twitter account (Figure 3).

An important aspect of the system is the dynamic load balancing algorithm. The algorithm regulates the system to operate in a solar-powered, grid-powered, or solar-powered and grid-powered mode (Figure 4). Dynamic load balancing is achieved by using the FPGA platform to program itself and use PWM signals to control the power flow to the refrigeration compressor.

The system becomes more complex due to the addition of batteries. The battery plays a dual role as a load and a source of power in the system. A control algorithm was designed to determine when the battery needs to be charged and when the battery is the source of power for the system. Careful design of the battery control ensures that the battery pack is always charged efficiently.

Conclusion

Using the LabVIEW Real-Time Module and the NI Single-Board RIO platform, we designed and built a field test prototype system that runs complex control algorithms and collects valuable engineering data while being easy to operate and debug. The system is now operating in a remote area in southern India, cooling milk every day. As we move toward mass production and commercialization, the data collected from this prototype will be used to improve the system and simplify the design.

Previous article:How do I install the DAQ Assistant in LabVIEW?

Next article:Developing an Automated Meter Reading System for Substations in India Using NI LabVIEW and CompactRIO

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Test Measurement Articles

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

MoreSelected Circuit Diagrams

MorePopular Articles

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

MoreDaily News

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

Guess you like

- Analog Multiplexer and Switch Configuration

- Build a "core" building together: front-line engineers talk about national chips, valid all year round (11 floors have been built)

- Principle of MCU reset

- Regarding the C216 issue, I want to make a combination lock, and I'm a newbie looking for advice from a master! !

- The use of SRAM in HPM6750 and the problems encountered

- Oscilloscope automobile turbocharger solenoid valve waveform and analysis

- Transformer voltage calculation

- Failure to send data in broadcast mode

- EEWORLD University - IGBT module technology, drive and application

- Mbed online compiler to be retired soon

NJU7074M

NJU7074M

京公网安备 11010802033920号

京公网安备 11010802033920号