Industrial motion control covers a range of applications, including inverter-based fan or pump control, factory automation with more complex AC drive control, and advanced automation applications such as robotics with advanced servo control. These systems require the detection and feedback of multiple variables, such as motor winding current or voltage, DC link current or voltage, rotor position and speed. Among considerations such as value-added functions such as condition monitoring, the end application requirements, system architecture, target system cost or system complexity will determine the choice of variables and the required measurement accuracy. It is reported that motors account for 40% of the world's total energy consumption, and international regulations are increasingly focusing on system efficiency throughout industrial motion applications. Therefore, these variables are becoming increasingly important, especially current and voltage.

This article will focus on current and voltage sensing in various motor control signal chain topologies based on motor power rating, system performance requirements, and end applications. In this context, the implementation of the motor control signal chain varies due to sensor selection, galvanic isolation requirements, analog-to-digital converter (ADC) selection, system integration, and system power and ground partitioning.

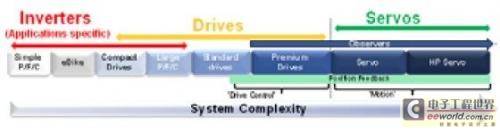

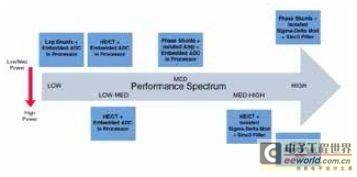

Figure 1. Industrial drive application map

Industrial Drive Application Spectrum

From simple inverters to complex servo drives, motor control applications cover a range of motor types, but all motors include a motor control system for a specific power level, and a processor that drives a pulse width modulator (PWM) module with varying levels of sensing and feedback. Figure 1 is a simplified diagram of the application spectrum, showing various systems with increasing complexity from left to right, starting with simple control systems such as pumps, fans, and compressors that can be implemented using simple microprocessors without precise feedback. As the system complexity increases (i.e., moving to the higher end of the spectrum), complex control systems require precise feedback and high-speed communication interfaces. Examples include vector controlled induction motors or permanent magnet motors with or without sensors, and high-power industrial drives (such as large pumps, fans, and compressors) designed for efficiency as shown in Figure 1. At the highest end of the spectrum are complex servo drives used in applications such as robotics, machine tools, and placement machines. As the system complexity increases, the sensing and feedback of variables become increasingly critical.

Drive Architecture System Partitioning

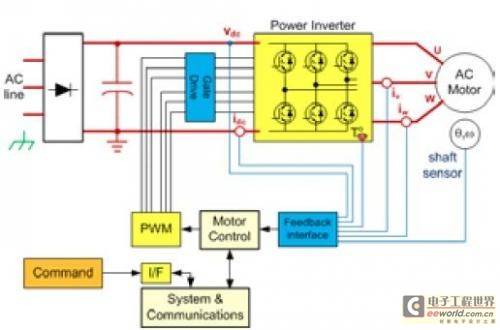

There are various problems we may encounter when designing a system to meet the needs of various industrial motion control applications. A generic motor control signal chain is shown in Figure 2.

Figure 2. Generic motor control signal chain

Isolation requirements are very important and often have a significant impact on the resulting circuit topology and architecture. There are two key factors to consider: why and where to isolate.

The classification of isolation required is determined by the former. Safety isolation of high voltage (SELV) may be required for protection against electric shock, or functional isolation for level translation between non-lethal voltages, or isolation may be required for data integrity and noise rejection. The location of isolation is often determined by the expected performance of the system. Motor control is often performed in a harsh environment full of electrical noise, and the designs used are often subject to hundreds of volts of common mode voltage, which may switch at frequencies exceeding 20 kHz and have very high transient dv/dt rise times. For this reason, higher performance systems and inherently noisy high power systems are often designed with the power stage isolated from the control stage. Whether a single processor or dual processor design is used will also affect the location of isolation. In lower performance, low power systems, isolation is often performed at the digital communication interface, which means that the power stage and control stage are at the same potential. Low-end systems have lower bandwidth communication interfaces that need to be isolated. Isolating the communication ports of high-end systems is often more difficult due to the high bandwidth requirements of high-end systems and the limitations of traditional isolation technology. But things are changing with the advent of magnetically isolated CAN and RS-485 transceiver products.

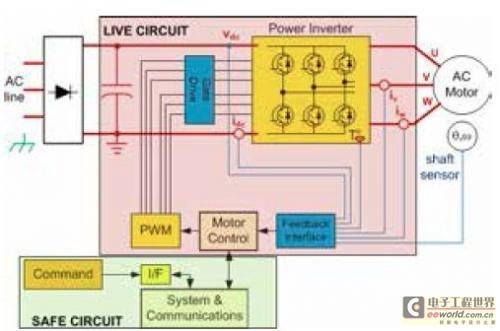

Two critical elements in high-performance closed-loop motor control designs are the PWM modulator outputs and the motor phase current feedback. Figures 3a and 3b show where safety isolation is needed, depending on whether the control stage shares the same potential as the power stage or is referenced to ground. In either case, the high-side gate driver and current sense nodes require isolation, but the isolation levels are different in Figure 3a, where only functional isolation is required, while in Figure 3b, human safety isolation (i.e., galvanic isolation) of these nodes is critical.

Figure 3a. Control stage referenced to power stage Figure 3b. Control stage referenced to ground

Measurement Techniques and Topologies for Current and Voltage Sensing

In addition to the system power and ground partitioning described above, the signal chain implemented for sensing current and voltage will also vary depending on sensor selection, galvanic isolation requirements, ADC selection, and system integration. Signal conditioning for high-fidelity measurements is not an easy task. For example, recovering small signals or transmitting digital signals in such a noisy environment is very challenging, and isolating analog signals is an even greater challenge. In many cases, the signal isolation circuit introduces phase delays that limit the dynamic performance of the system. Phase current sensing is particularly difficult because the node is connected to the same circuit node as the gate driver output in the core of the power stage (inverter module), so the requirements for isolating power and switching transients are also the same. The measurement signal chain (technology, signal conditioning, and ADC) to be implemented in the motor control system is usually determined by the following three key factors:

1. The point or node in the system that determines the measurement requirements.

2. The motor power level and the final sensor selected (with or without isolation). Sensor selection greatly affects the choice of ADC, including converter architecture, functions, and analog input range.

3 End application. This can drive the need for higher resolution, accuracy, or speed in the sensing signal chain. For example, sensorless control over a wide speed range requires more, more frequent, and more accurate measurements. The end application also affects the requirements for ADC functionality. For example, multi-axis control may require an ADC with a higher channel count.[page]

Current and Voltage SensorsThe

most common current sensors used in motor control are shunt resistors, Hall Effect (HE) sensors, and current transformers (CTs). Although shunt resistors provide isolation and suffer losses at higher currents, they are the most linear, lowest cost, and suitable for both ac and dc measurements. Signal level attenuation to limit shunt power loss typically limits shunt applications to 50 A or less. CT sensors and HE sensors provide inherent isolation, allowing them to be used in higher current systems. However, they are more expensive, and solutions using these sensors may not be as accurate as solutions using shunt resistors due to their inherent poor initial accuracy or poor accuracy over temperature.Motor

Current Measurement Locations and TopologiesIn

addition to the sensor type, there are many options for motor current measurement nodes. The average DC link current is sufficient for control needs, but in more advanced drives, the motor winding current is used as the primary feedback variable. Direct phase winding current measurement is ideal and can be used in high-performance systems. However, winding current can be measured indirectly using shunts on each low-side inverter leg or using a single shunt in the DC link. The advantage of these methods is that the shunt signals are all referenced to a common supply, but extracting the winding current from the DC link requires sampling to be synchronized with the PWM switching. Direct phase winding current measurement can be performed using any of the above current sensing techniques, but the shunt resistor signal must be isolated. High common-mode amplifiers can provide functional isolation, but personnel safety isolation must be provided by isolated amplifiers or isolated modulators.

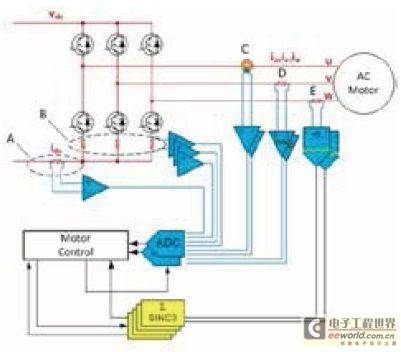

Figure 4. Isolated and non-isolated motor current feedback

Figure 4 shows the various current feedback options described above. While only one of these options is needed for control feedback, the DC link current signal can also be used as a backup signal for protection.

As mentioned previously, the system power and ground partitioning will determine the isolation classification required and, therefore, the appropriate feedback. The target performance of the system will also affect the sensor selection or measurement technology. Looking across the performance spectrum, many configurations are possible.

Low Performance Example: Power and Control Stages on Common Potential, Sensing Option A or B

Using pin shunts is one of the most cost-effective motor current measurement techniques. In this case, the power stage shares the same potential as the control stage, there is no common mode to deal with, and the output of Option A or Option B can be directly connected to the signal conditioning circuitry and ADC. This topology is common in low-power and low-performance systems with an ADC embedded in a microprocessor.

High Performance Example: Control Stage Ground, Sensing Options C, D, or E

In this example, personnel safety isolation is required. Sensing options C, D, and E are all possible. Of all three options, option E provides the best quality current feedback, and as a high performance system, there may be an FPGA or other form of processing in the system to provide a digital filter for the isolated modulator signal. For the ADC selection of option C, a discrete isolated sensor (most likely a closed loop HE) is typically used to achieve higher performance than what can be achieved with current embedded ADC products. Option D in this configuration is an isolated amplifier compared to a common mode amplifier because safety isolation is required. An isolated amplifier will limit performance, so an embedded ADC solution will suffice. This option provides the lowest fidelity current feedback compared to options C or E. In addition, while the embedded ADC can be considered "free" and the isolated amplifier can be considered "cheap", the implementation usually requires additional components for offset compensation and level shifting for ADC input range matching, which increases the overall cost of the signal chain.

In motor control designs, many topologies can be used to sense motor current, and there are many factors to consider, such as cost, power level, and performance level. An important goal for most system designers is to improve current sensing feedback to increase efficiency within their cost targets. For higher end applications, current feedback is critical not only for efficiency, but also for other system performance measures such as dynamic response, noise, or torque ripple. Clearly, there is a continuum of performance from low to high across the various topologies available, with Figure 5 providing a rough mapping showing low power and high power options.

Figure 5. Current sensing topology performance spectrum

Motor control system designer goals, needs and trends: Transition from HE sensors to shunt resistors

Shunt resistors coupled with isolated ∆-modulators provide the best quality current feedback, where the current level is low enough to fully meet the shunt requirements. Currently, there is a clear trend among system designers to transition from HE sensors to shunt resistors, and designers are also leaning towards isolated modulator solutions compared to isolated amplifier solutions. Simply replacing the sensor itself can reduce bill of materials (BOM) and PCB assembly costs and improve sensor accuracy. Shunt resistors are not sensitive to magnetic fields or mechanical vibrations. System designers who replace HE sensors with shunt resistors often choose isolated amplifiers and continue to use the ADCs previously used in HE sensor-based designs to limit level changes in the signal chain. However, as mentioned earlier, no matter how good the ADC performance is, the performance will be limited by the performance of the isolated amplifier.

And further replacing the isolated amplifier and ADC with an isolated ∆-modulator can eliminate performance bottlenecks and greatly improve the design, typically taking it from 9 to 10 bits of high-quality feedback to 12 bits. In addition, the digital filter required to process the V-modulator output can be configured to implement a fast OCP loop, thereby eliminating the analog overcurrent protection (OCP) circuit. Therefore, any BOM analysis should include not only the isolated amplifier, the original ADC, the signal conditioning between the two, but also the OCP devices that can be eliminated. The AD701A isolated V-modulator is based on ADI's iCoupler technology and has a differential input range of ±250 mV (typically ±320 mV full scale for OCP), which is particularly suitable for resistive shunt measurement and is an ideal product choice to expand this trend. The analog modulator continuously samples the analog input, and the input information is contained in the digital output stream in the form of a data stream density, with a data rate of up to 20 MHz. The original information can be reconstructed through an appropriate digital filter (typically a Sinc3 filter for precision current measurement). Since a trade-off can be made between conversion performance and bandwidth or filter group delay, a simpler and faster filter can provide a fast OCP response on the order of 2μs, which is very suitable for IGBT protection.

The need for smaller shunt resistors

From the signal measurement side, some of the main challenges today are related to selecting shunt resistors because of the trade-offs between sensitivity and power consumption. Large resistor values will ensure that the entire or as large as possible analog input range of the modulator is used, thereby achieving the maximum dynamic range. However, large resistor values also result in voltage drops and reduced efficiency due to the I2×R losses in the resistor. Nonlinearity due to the heating effect of the resistor itself can also be a challenge with larger resistors. Therefore, system designers face a trade-off and further aggravation, and they often need to select an appropriately sized shunt resistor to meet the needs of various models and motors at different current levels. Maintaining dynamic range is also a challenge when faced with peak currents that are several times the rated current of the motor and need to reliably capture both values. The ability to control the peak current at the start of the system can vary greatly from design to design, ranging from tight control of a fluctuation of, for example, 30% above the rated current, to a factor of up to 10 times the rated current. Acceleration and load or torque changes can also generate peak currents. However, peak currents in systems are typically in the range of 4 times the rated current of the drive design.

Faced with these challenges, system designers are looking for high-performance ∆-modulators with wider dynamic range or with higher signal-to-noise and signal-to-distortion (SINAD) ratios. The latest isolated ∆-modulator products have 16-bit resolution and guarantee performance up to 12 bits of effective number of bits (ENOB).

SINAD = (6.02 N + 1.76) dB, where N = ENOB

Following the trend of using shunt resistors in low-power drives, motor drive manufacturers are also looking to increase the power rating of drives that can utilize this topology for performance and cost reasons. The only feasible way is to use smaller shunt resistors, which requires the introduction of higher-performance modulator cores to discern the reduced signal amplitude.

System designers, especially servo designers, are still exploring ways to improve system response by reducing the analog-to-digital conversion time or by reducing the group delay of the digital filters associated with isolated ∆-modulator and shunt resistor topologies. As mentioned earlier, there is a trade-off between conversion performance and bandwidth or filter group delay. Simpler and faster filters provide faster response but reduce performance. System designers analyze the effect of filter wavelength or decimation ratio and then make tradeoffs based on their end application needs. Increasing the modulator clock rate can help, but many designers have implemented operation at the maximum clock rate of 20 MHz supported by the AD7401A. One disadvantage of increasing the clock rate is the potential for radiation and interference (EMI) effects. At the same clock rate, a higher performance modulator improves the tradeoff between group delay and performance, allowing faster response times with less performance degradation.

Industry's Best-Performing Isolated-V-Modulators

Clearly, higher-performing isolated-V-Modulators address a variety of needs and developments in industrial motor design and improve the power efficiency of motor drives by reducing the size of shunt resistors, improving sensorless control schemes, and enabling control of high-efficiency interior permanent magnet motors (IPMs). ADI's AD7403 is the next generation of the AD7401A, offering a wider dynamic range at the same 20 MHz external clock rate. This gives designers more flexibility in selecting shunt resistor size, optimizing drive-to-motor matching, improving the accuracy of rated and peak current measurements, reducing the impact of a single shunt resistor size for a range of motor models, and enabling the use of shunt resistors to replace HE sensors at higher current levels. In addition, dynamic response can be improved by reducing measurement latency. The AD7403's isolation scheme also allows for a higher continuous operating voltage (VIORM) than the previous generation AD7400A and AD7401A, which can improve system efficiency by using higher DC bus voltages and lower motor currents.

Broader System Solutions Including the ADSP-CM40x Mixed-Signal Control ProcessorsAs

mentioned previously, implementing a delta-modulator requires a digital filter in the system. This is typically implemented using an FPGA or digital ASIC. The advent of the ADSP-CM408F mixed-signal control processor, which includes Sinc3 filter hardware to interface directly to the AD740x family of isolated delta-modulators, has the potential to accelerate the adoption of resistive shunt current sensing coupled to isolated delta-modulators. As discussed in this article, resistive shunt current sensing has historically been considered expensive by designers due to the increased system complexity in the digital domain and the associated (FPGA) cost. The ADSP-CM408F is a cost-effective solution that will allow many designers who were previously constrained by cost targets to consider this technology.

Previous article:Additional Phase Noise Test Techniques and Considerations

Next article:Achieve non-contact stable voltage measurement

- Popular Resources

- Popular amplifiers

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- How to measure the quality of soft start thyristor

- How to use a multimeter to judge whether a soft starter is good or bad

- What are the advantages and disadvantages of non-contact temperature sensors?

- In what situations are non-contact temperature sensors widely used?

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- What are the functions of the Internet of Vehicles? What are the uses and benefits of the Internet of Vehicles?

- Power Inverter - A critical safety system for electric vehicles

- Analysis of the information security mechanism of AUTOSAR, the automotive embedded software framework

- FPGA Design Flow.zip

- Review summary: Telink's new generation of low-power, high-performance multi-protocol wireless kit B91, free review and trial

- Analyze and constrain timing in ISE

- Altera Recommended HDL Coding Style 2014.pdf

- [Jihai APM32E103VET6S MINI development board review] FLASH test

- I sent the PCB drawings made by a PCB novice to the PCB manufacturer. They said there was a problem with the drawings. I hope the experts can take a look.

- What kind of motors are generally used in surveillance camera pan/tilts?

- Various LED ring light lighting pattern reference designs

- Find a circuit

- CAN waveform

5962-8770601GA

5962-8770601GA

京公网安备 11010802033920号

京公网安备 11010802033920号