Due to the complexity of deep hole processing conditions and the lack of in-depth understanding of the physical sources that cause these state changes, there is currently no more complete method and system for monitoring the deep hole drilling process. Traditional single-factor monitoring and single-factor model analysis methods have great limitations. The influence of random factors is too great, and it is difficult to correctly reflect the real situation of the system.

This paper mainly studies the monitoring scheme and signal analysis of deep hole drilling process. A multi-sensor deep hole drilling force and drilling vibration signal acquisition device is designed. The multi-information fusion technology is used to analyze and process the various signals collected during the deep hole drilling process to obtain accurate judgment samples, providing a criterion for the monitoring and control of the drilling process. The cutting force of

the monitoring scheme and device

contains a lot of information in the cutting process. When almost all cutting faults occur, the cutting force signal changes accordingly. However, the characteristic signals shown by different cutting processing methods are also different. Judging tool wear or breakage based on this single criterion alone will cause certain false alarms. Therefore, according to the characteristics of the deep hole drilling system, this study designs a multi-sensor force and vibration measurement device for deep hole drilling, which has the advantages of strong versatility, fast dynamic response, and easy installation and use.

Figure 1 Schematic diagram of multi-sensor force and vibration measurement device

Experimental research

This experimental study collected two working condition signals of normal and failure during deep hole processing. Drill bits with different degrees of wear and cutting parameters are used to obtain signals of different experimental states and the degree of influence on the signals. The data acquisition device uses 4 channels to collect force, torque, vertical and horizontal vibration signals respectively.

Data acquisition under normal drilling conditions:

the change law of tool status signal when the tool is initially worn and normally worn;

the change law of tool status signal when the speed is changed;

the change law of tool status signal when the feed rate is changed.

Data acquisition under simulated fault conditions :

the change law of tool status signal when the tool is rapidly worn and damaged;

the change law of tool status signal when the chip is blocked;

the change law of tool status signal when the guide block is broken.

Signal analysis:

Since the measurement signal not only contains useful information reflecting the working state of the object, but also contains a lot of useless background noise, the useful information reflecting the working state is often submerged in the useless background noise, and it is generally difficult to directly discover and extract it. In the time domain waveform analysis of the four signals of force, torque, vertical vibration and horizontal vibration, it is found that the original signal is not very different in the time domain and cannot be used for online monitoring of the drill bit. For this reason, the original signal should be processed.

When the frequency domain signal analysis of the four signals is performed, it is found that the force and torque signals have no obvious spectral peaks in the frequency domain, and there is no obvious change law. Only when the tool is damaged does it have a characteristic frequency, so time series analysis is applied to the force and torque signals. The AR model is used to estimate its parameters and obtain the residual equation of the force time series model.

The vibration signal changes significantly in the frequency domain signal. The spectrum analysis of the vibration signal in the horizontal and vertical directions is shown in Figure 2.

Figure 2 Power spectrum analysis of low-frequency vibration signal

The characteristic of the frequency spectrum change of the power spectrum density of the vibration signal in the low-frequency band is that as the tool wear increases, the main peak amplitude increases rapidly and then tends to be gentle, while the main peak frequency position moves from high frequency to low frequency. When the tool is rapidly worn and close to damage, the main peak frequency in the horizontal direction is concentrated at about 400Hz, and many new spectrum peaks appear; the main peak frequency in the vertical direction is concentrated at about 210Hz, and many new spectrum peaks also appear. This change reflects the generation and development of tool wear, which stimulates the harmonic components of the tool-workpiece-machine tool processing system through cutting force, resulting in changes in the vibration modal parameters of the system. The appearance of multiple spectrum peaks disperses the signal energy, so the spectrum peak amplitude increases slowly, and the increase in cutting damping caused by the deterioration of the contact area between the tool and the workpiece reduces the main peak frequency position of the vertical vibration. The

change law of the power spectrum in the high-frequency band is basically the same as that in the low-frequency band, but the law is not as prominent as that in the low-frequency band. The frequency of the main peak amplitude appearing in the high-frequency region is very small, and there are few spectrum peaks. This is because the forced vibration source of the cutting processing system is generally within 1,000Hz. Therefore, the high frequency spectrum can effectively isolate or weaken the harmonic components of the processing system. Whether

the pattern recognition

state classification can be successful depends to a large extent on the feature analysis and the selection of feature quantities. The dynamic system of deep hole processing is a random process, which is difficult to analyze with a certain deterministic time function. The purpose of feature analysis is to transform the original signal into a feature quantity and find out its relationship with the working condition. There are many such feature quantities, but to reflect the regularity, sensitivity and clustering type of the working condition state in the pattern space, the separability is not the same. It is necessary to select feature quantities with good regularity and strong sensitivity as pattern vectors based on feature analysis to make them have better separability.

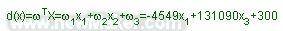

This experimental study analyzed the characteristics of vibration, axial force and torque signals in the time domain and frequency domain respectively. On the basis of using time series models, power spectra and autocorrelation spectra, the characteristic spectrum peaks of horizontal vibration and the residual variance of the time series model of force were selected as pattern vectors, and the perceptron algorithm was used to obtain the weighted vector w=(-4,540, 131,090, 300)T. Therefore, the classification function is obtained:

Experiments have proved that the designed multi-sensor force and vibration measuring device for deep hole drilling is simple to install, reliable in operation, and the combined signals are complementary, which improves the accuracy of monitoring and is suitable for monitoring the status of drilling tools during deep hole drilling.

The vibration signal has significant characteristics in the frequency domain that reflect the wear state of the tool. Under different drilling conditions and drilling amounts, its power spectrum changes differently, but the trend of change is consistent. The

amplitude of the main peak of horizontal vibration and the residual variance of the force are selected as feature vectors. The mode vector is constructed. It can fully reflect the operation status of the deep hole processing system. (end)

Previous article:Two wheels processed by CNC--CNC tools and digital measuring instruments

Next article:Research on dynamic signal detection of vibration tapping tool wear

- New IsoVu™ Isolated Current Probes: Bringing a New Dimension to Current Measurements

- Modern manufacturing strategies drive continuous improvement in ICT online testing

- Methods for Correlation of Contact and Non-Contact Measurements

- Keysight Technologies Helps Samsung Electronics Successfully Validate FiRa® 2.0 Safe Distance Measurement Test Case

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Seizing the Opportunities in the Chinese Application Market: NI's Challenges and Answers

- Tektronix Launches Breakthrough Power Measurement Tools to Accelerate Innovation as Global Electrification Accelerates

- Not all oscilloscopes are created equal: Why ADCs and low noise floor matter

- Enable TekHSI high-speed interface function to accelerate the remote transmission of waveform data

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- STMicroelectronics discloses its 2027-2028 financial model and path to achieve its 2030 goals

- 2024 China Automotive Charging and Battery Swapping Ecosystem Conference held in Taiyuan

- State-owned enterprises team up to invest in solid-state battery giant

- The evolution of electronic and electrical architecture is accelerating

- The first! National Automotive Chip Quality Inspection Center established

- BYD releases self-developed automotive chip using 4nm process, with a running score of up to 1.15 million

- GEODNET launches GEO-PULSE, a car GPS navigation device

- Should Chinese car companies develop their own high-computing chips?

- Infineon and Siemens combine embedded automotive software platform with microcontrollers to provide the necessary functions for next-generation SDVs

- Continental launches invisible biometric sensor display to monitor passengers' vital signs

- ARM programming mode and 7 modes

- Resource Download: Qorvo Wi-Fi Graphics File: 802.11ax / 802.11ac for the Smart Home

- Award-winning live broadcast: Tektronix's three-detection "detector" will help you overcome the pitfalls of probes

- Platform-based variable speed motor solution development

- Evaluation report summary: AI development board based on Allwinner - R329 development board

- 【GD32E503 Review】Chip internal interface test

- TI Power

- KuKa band satellite transponder

- Super summary: 25 op amp parameters explained in detail

- New support for STM32WB55 in MicrPython

ICCV2023 Paper Summary: Embodied Vision: Active Agents, Simulation

ICCV2023 Paper Summary: Embodied Vision: Active Agents, Simulation Control system development based on MODBUS/UDP

Control system development based on MODBUS/UDP

京公网安备 11010802033920号

京公网安备 11010802033920号