From health monitors and fitness trackers to virtual reality headsets, wearable electronics have become part of our daily lives. Researchers at the University of Washington recently published a paper in the journal Advanced Energy Materials, saying that they have pioneered a flexible wearable thermoelectric device that can convert body heat into electricity. The device has properties that are usually difficult to combine: it is both soft and stretchable, and strong and efficient.

"If we can capture the heat energy that is wasted in the surrounding environment, it's a 100 percent gain," said Mohammed Malakudi, assistant professor of mechanical engineering at the University of Washington. "But to use this energy for self-powered electronic devices, we need higher power density. Stretchable electronics made with 3D printing can improve efficiency and enable seamless integration into wearable devices."

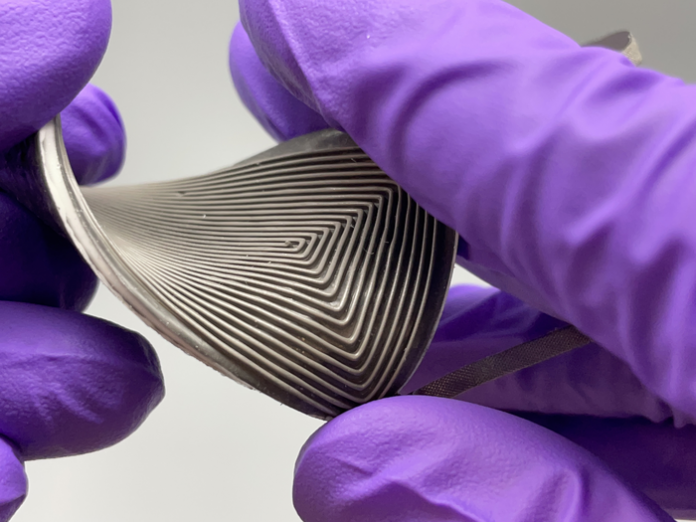

The researchers created a prototype device that remained fully functional even after more than 15,000 stretching cycles at 30 percent strain, which is ideal for wearable electronics and flexible robotics. The device also increased power density by 6.5 times compared to previous stretchable thermoelectric generators.

To create this prototype device, the researchers 3D printed composite materials with engineered functional and structural properties in each layer, and the filler material contains liquid metal alloys that provide high electrical and thermal conductivity. These alloys address the limitations of previous devices, including the inability to stretch, inefficient heat transfer, and complex manufacturing processes. The team also embedded hollow microspheres to direct heat to the semiconductor in the core layer and reduce the weight of the device.

The researchers said they were able to print the device onto stretchable textiles and curved surfaces, suggesting that future devices could be applied to clothing and other objects. A unique aspect of this research is that it covers the entire range from material synthesis to device fabrication and characterization, giving the researchers freedom to design new materials and exercise creativity.

Previous article:Apple AR/MR devices are expected to replace iPhones in the next 10 years, and the price can reach 17,000 yuan

Next article:New wearable sensor can detect multiple compounds in human sweat

- Popular Resources

- Popular amplifiers

- e-Network Community and NXP launch Smart Space Building Automation Challenge

- The Internet of Things helps electric vehicle charging facilities move into the future

- Nordic Semiconductor Launches nRF54L15, nRF54L10 and nRF54L05 Next Generation Wireless SoCs

- Face detection based on camera capture video in OPENCV - Mir NXP i.MX93 development board

- The UK tests drones equipped with nervous systems: no need to frequently land for inspection

- The power of ultra-wideband: reshaping the automotive, mobile and industrial IoT experience

- STMicroelectronics launches highly adaptable and easy-to-connect dual-radio IoT module for metering and asset tracking applications

- This year, the number of IoT connections in my country is expected to exceed 3 billion

- Infineon Technologies SECORA™ Pay Bio Enhances Convenience and Trust in Contactless Biometric Payments

- LED chemical incompatibility test to see which chemicals LEDs can be used with

- Application of ARM9 hardware coprocessor on WinCE embedded motherboard

- What are the key points for selecting rotor flowmeter?

- LM317 high power charger circuit

- A brief analysis of Embest's application and development of embedded medical devices

- Single-phase RC protection circuit

- stm32 PVD programmable voltage monitor

- Introduction and measurement of edge trigger and level trigger of 51 single chip microcomputer

- Improved design of Linux system software shell protection technology

- What to do if the ABB robot protection device stops

- Learn ARM development(19)

- Learn ARM development(14)

- Learn ARM development(15)

- Analysis of the application of several common contact parts in high-voltage connectors of new energy vehicles

- Wiring harness durability test and contact voltage drop test method

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- From probes to power supplies, Tektronix is leading the way in comprehensive innovation in power electronics testing

- Sn-doped CuO nanostructure-based ethanol gas sensor for real-time drunk driving detection in vehicles

- Design considerations for automotive battery wiring harness

- Do you know all the various motors commonly used in automotive electronics?

- ESP32, how to operate the configuration file?

- Summary of bare metal program burning method for embedded Linux development board

- Design of reversing radar based on MSP430

- 3D Printed Strokes A 3D Printer

- Canaan-K510 development kit development environment construction (try and ask for help)

- Atmel Studio has stopped working?

- How to calculate the primary inductance of the flyback power supply switch transformer

- XMC4800 Review (VI) Making a Simple Web Browser

- [GD32E231 DIY Contest]——04. Build an IoT cloud server based on MQTT communication

- EEWORLD University Hall----Introduction to UCD3138 digital power controller architecture and power peripherals

Low Power Analog Techniques for Wearable Biosensors

Low Power Analog Techniques for Wearable Biosensors On-chip ECG design and self-powered biomedical device design (Singapore National University courseware)

On-chip ECG design and self-powered biomedical device design (Singapore National University courseware)

京公网安备 11010802033920号

京公网安备 11010802033920号