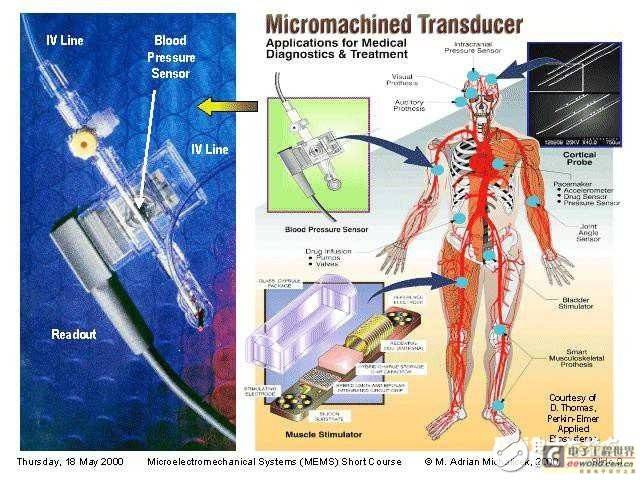

With the development of wearable smart devices, especially medical wearable smart devices, they mainly rely on MEMS sensors to detect various body information of the wearer. So what are MEMS sensors?

MEMS, or Microelectro Mechanical Systems, is a multidisciplinary frontier research field developed on the basis of microelectronics technology. After more than 40 years of development, it has become one of the major scientific and technological fields that has attracted worldwide attention. It involves multiple disciplines and technologies such as electronics, mechanics, materials, physics, chemistry, biology, and medicine, and has broad application prospects.

As of 2010, there are about 600 companies in the world engaged in the research and production of MEMS, and have developed hundreds of products including micro pressure sensors, accelerometers, micro inkjet print heads, and digital micromirror displays, among which MEMS sensors account for a considerable proportion.

MEMS sensors are new sensors made using microelectronics and micromachining technology. Compared with traditional sensors, they are small, light, low cost, low power consumption, high reliability, suitable for mass production, easy to integrate and intelligent. At the same time, the characteristic size of micrometers enables it to perform functions that traditional mechanical sensors cannot achieve.

Its main applications are as follows:

1. Application in medical treatment

MEMS sensors are used in non-invasive fetal heart rate detection. Detecting fetal heart rate is a highly technical task. Since the fetal heart rate is very fast, between 120 and 160 times per minute, it is difficult to measure accurately with a traditional stethoscope or even an ultrasonic Doppler instrument that only has an amplification function and manual counting. Ultrasonic Doppler fetal heart rate monitors with digital display functions are expensive and are only used in a few large hospitals. They are not popular in medium and small hospitals and rural areas. In addition, the ultrasonic vibration wave acting on the fetus will have a great adverse effect on the fetus. Although the detection dose is very low, it also belongs to the category of destructive detection and is not suitable for regular, repeated inspections and home use.

Based on VTI's MEMS accelerometer, a non-invasive fetal heart rate detection method is proposed, and a simple, easy-to-learn, intuitive and accurate medical auxiliary instrument for clinical diagnosis and maternal self-examination between a fetal heart rate stethoscope and a Doppler fetal monitor is developed.

The fetal heart rate is converted into an analog voltage signal through an acceleration sensor, and the difference is amplified by the instrument amplifier used for pre-amplification. Then a series of intermediate signal processing such as filtering is performed, and the analog voltage signal is converted into a digital signal by an A/D converter. It is input into the microcontroller through an optical isolation device for analysis and processing, and finally the processing result is output.

The fetal heart rate detector designed based on MEMS acceleration sensor can be used as a terminal to make a remote fetal heart monitoring system after appropriate improvement. The central signal acquisition and analysis monitoring host at the hospital end gives automatic analysis results, and the doctor diagnoses the results. If there is a problem, the pregnant woman is notified to come to the hospital in time. This technology is conducive to pregnant women to check the condition of the fetus at any time, which is beneficial to the health of the fetus and the pregnant woman.

2. Application in automotive electronics

MEMS pressure sensors are mainly used to measure airbag pressure, fuel pressure, engine oil pressure, intake pipe pressure and tire pressure. This sensor uses single crystal silicon as material, and uses MEMS technology to make a force-sensitive diaphragm in the middle of the material, then diffuses impurities on the diaphragm to form four strain resistors, and then connects the strain resistors into a circuit in the Wheatstone bridge method to obtain high sensitivity.

There are several common forms of automotive MEMS pressure sensors, including capacitive, piezoresistive, differential transformer, and surface acoustic wave. The principle of MEMS accelerometers is based on Newton's laws of classical mechanics. They are usually composed of a suspension system and a detection mass. The acceleration is detected by the offset of a micro silicon mass block. They are mainly used in automotive airbag systems, anti-skid systems, car navigation systems, and anti-theft systems. In addition to capacitive and piezoresistive types, MEMS accelerometers also have piezoelectric, tunnel current, resonant, and thermocouple types. Among them, capacitive MEMS accelerometers have the characteristics of high sensitivity and minimal temperature influence, and are the mainstream products among MEMS micro accelerometers.

Micro gyroscope is an angular rate sensor, mainly used for GPS signal compensation of car navigation and car chassis control system. There are several types, such as vibration type and rotor type. The most widely used one is the vibration gyroscope, which uses the Coriolis effect generated by the vibration mass block of single crystal silicon or polycrystalline silicon when it is driven by the base to sense the angular velocity. For example, when the car is turning, the system measures the angular velocity through the gyroscope to indicate whether the steering wheel is turned in place, and actively applies appropriate brakes on the inner or outer wheels to prevent the car from leaving the lane. Usually, it forms an active control system together with a low accelerometer.

3. Applied to sports tracking system

In the daily training of athletes, MEMS sensors can be used to measure 3D human motion and record every movement. Coaches analyze the results and compare them repeatedly to improve the performance of athletes. With the further development of MEMS technology, the price of MEMS sensors will also decrease, which can also be widely used in mass gyms.

In skiing, the pressure sensor, acceleration sensor, gyroscope and GPS in 3D motion tracking can give users extremely accurate observation capabilities. In addition to providing movement data of the ski board, it can also record the user's position and distance. The same is true for surfing. The 3D motion tracking installed on the surfboard can record information such as wave height, speed, surfing time, paddle board distance, water temperature and calories consumed.

Previous article:

Next article:Gas detectors helped

- Popular Resources

- Popular amplifiers

- ADLINK Launches AmITX Mini-ITX Motherboard to Power Edge AI and IoT Innovation

- e-Network Community and NXP launch Smart Space Building Automation Challenge

- The Internet of Things helps electric vehicle charging facilities move into the future

- Nordic Semiconductor Launches nRF54L15, nRF54L10 and nRF54L05 Next Generation Wireless SoCs

- Face detection based on camera capture video in OPENCV - Mir NXP i.MX93 development board

- The UK tests drones equipped with nervous systems: no need to frequently land for inspection

- The power of ultra-wideband: reshaping the automotive, mobile and industrial IoT experience

- STMicroelectronics launches highly adaptable and easy-to-connect dual-radio IoT module for metering and asset tracking applications

- This year, the number of IoT connections in my country is expected to exceed 3 billion

- Intel promotes AI with multi-dimensional efforts in technology, application, and ecology

- ChinaJoy Qualcomm Snapdragon Theme Pavilion takes you to experience the new changes in digital entertainment in the 5G era

- Infineon's latest generation IGBT technology platform enables precise control of speed and position

- Two test methods for LED lighting life

- Don't Let Lightning Induced Surges Scare You

- Application of brushless motor controller ML4425/4426

- Easy identification of LED power supply quality

- World's first integrated photovoltaic solar system completed in Israel

- Sliding window mean filter for avr microcontroller AD conversion

- What does call mean in the detailed explanation of ABB robot programming instructions?

- Europe's three largest chip giants re-examine their supply chains

- Breaking through the intelligent competition, Changan Automobile opens the "God's perspective"

- The world's first fully digital chassis, looking forward to the debut of the U7 PHEV and EV versions

- Design of automotive LIN communication simulator based on Renesas MCU

- When will solid-state batteries become popular?

- Adding solid-state batteries, CATL wants to continue to be the "King of Ning"

- The agency predicts that my country's public electric vehicle charging piles will reach 3.6 million this year, accounting for nearly 70% of the world

- U.S. senators urge NHTSA to issue new vehicle safety rules

- Giants step up investment, accelerating the application of solid-state batteries

- Guangzhou Auto Show: End-to-end competition accelerates, autonomous driving fully impacts luxury...

- EEWORLD University Hall----Computer Organization and Design: RISC-V (Zhejiang University)

- TMS320F28335 ADC Explanation

- Research on battery charging method

- V850E/Dx3: Next-generation 32-bit automotive instrument cluster microcontroller family

- The domestic operating system RT-Thread seems to be more powerful and can enter the automotive field

- Research on a novel power factor correction chip

- Using SPMC75F2313A to implement LIN node

- Getting Started with CircuitPython for the Raspberry Pi Pico

- Switching Power Supply Interest Group Task 06

- AT32F4xx Standard Library BSP&Pack Application Guide

TC1039NECHRT

TC1039NECHRT

京公网安备 11010802033920号

京公网安备 11010802033920号