Decoding infrared forehead thermometer: technical principles, disassembly analysis, design solutions, circuit solutions and other technical solutions

[Copy link]

This post was last edited by Rambo on 2020-3-12 13:45

Forehead Thermometer

The sudden outbreak of COVID-19 has had a negative impact on the growth of several global industrial chains. However, the epidemic has also made epidemic prevention materials, which usually have a stable demand, suddenly become in short supply, such as masks, alcohol, and disinfectant. At present, companies in many cities have sounded the clarion call to resume work, and forehead thermometers have become a new in-demand product.

Returning to work is very important, and prevention and control measures are essential. In addition to wearing masks, temperature screening has also become an important line of defense in epidemic control. By identifying people with abnormal body temperatures, taking measures such as timely detection and early isolation can effectively prevent the spread of the epidemic.

At present, various transportation checkpoints, stations, hospitals, residential areas, supermarkets, enterprises, institutions and other places with heavy traffic are using this infrared forehead thermometer to measure body temperature.

Temperature detection tool classification

Temperature detection tools are divided into two categories: contact and non-contact:

Contact type:

(1) Glass thermometer (mercury thermometer): It is the most common thermometer. It can keep the mercury column in its original position as the body temperature rises, making it easy for users to observe at any time.

(2) Electronic thermometer: It uses the definite relationship between the physical parameters of certain substances (such as resistance, voltage, current, etc.) and the ambient temperature to display the body temperature in digital form.

Contactless:

Infrared body temperature detector (forehead thermometer, ear thermometer, etc.): By measuring the radiation temperature of the eardrum or forehead, the human body temperature is measured non-contactly.

Traditional contact thermometers have a long testing time and the equipment needs to come into contact with the patient. There is a risk of cross-infection when used on a large scale and they are not suitable for rapid screening in public places.

Forehead thermometers, a non-contact temperature measuring instrument, have become a key material for epidemic prevention and control. Unlike the mercury thermometers and electronic thermometers used at home, "forehead thermometers" measure body temperature based on the infrared radiation energy emitted by the human body, so they are also called handheld infrared thermometers.

Disassembly and analysis of infrared forehead thermometer

In order to better understand the technical principle of the infrared forehead thermometer, let's first disassemble this forehead thermometer to understand its internal structure. After disassembling it, we will find that its core technology lies in the infrared sensor and the main control board.

Infrared forehead thermometer structure diagram

Technical principle of infrared forehead thermometer

All objects with a temperature above zero (-273.15℃) are constantly emitting infrared energy into the surrounding space. Its radiation characteristics, radiation energy, wavelength distribution, etc. are closely related to the surface temperature of the object. Conversely, by measuring the infrared energy radiated by the object itself, its surface temperature can be accurately determined. This is the mechanism of infrared radiation temperature measurement.

The human body, like other organisms, also radiates infrared energy to the surroundings. Its wavelength is generally 9-13μm, which is in the near-infrared band of 0.76-100μm. Since the light within this wavelength range is not absorbed by the air, that is to say, the size of the infrared radiation from the human body has nothing to do with the environmental impact, but is only related to the amount of energy stored and released by the human body. Therefore, the surface temperature of the human body can be accurately determined by measuring the infrared energy radiated by the human body itself. The human infrared temperature sensor is designed and manufactured based on this principle.

Infrared temperature sensor

At present, there are mainly the following types of infrared temperature sensors on the market, depending on the materials used for energy conversion:

(1) Pyroelectric type: triglycine sulfate, lithium tantalate, etc.

(2) Thermopile type: N-type and P-type polysilicon

(3) Diode type: single crystal or polycrystalline PN junction

(4) Thermal capacitor type: dual material film

(5) Thermistor type: vanadium oxide, amorphous silicon, etc. In fact, these types only differ in the conversion method and material energy efficiency ratio after receiving infrared energy.

Currently, the infrared sensors used in ear and forehead thermometers are all thermopile type, and the basic physical principle is the Seebeck effect.

Thermopile temperature sensor parameter indicators:

Measuring range: -50℃-100℃;

Measurement accuracy: within 0.1℃, within ±0.1%;

Working temperature: -20℃-+85℃;

Maximum measuring distance: ≦0-50mm (300-500mm with lens)

Output voltage: 0-10mV;

The maximum range of the thermopile temperature sensor can be -60℃ to +1200℃

There are two main packaging forms of infrared thermopile sensor finished product: TO46 (TO18)/TO39 (TO5);

Infrared forehead temperature gun chip

The core chip of the infrared temperature gun is mainly composed of ADC chip and control chip design, which can realize functions such as button control, LCD display, and power detection.

Working process of infrared thermometer: infrared thermometer is composed of optical system, photoelectric detector, signal amplifier and signal processing, display output and other parts. The optical system collects the infrared radiation energy of the target within its field of view. The size of the field of view is determined by the optical parts and position of the thermometer. The infrared radiated by the object to be measured first enters the optical system of the thermometer, and then the optical system collects the incident infrared rays to make the energy more concentrated; the collected infrared rays are input into the photoelectric detector. The key component of the detector is the infrared sensor, whose task is to convert the optical signal into an electrical signal; the electrical signal output from the photoelectric detector is converted into the temperature value of the target to be measured after being corrected by the amplifier and signal processing circuit according to the algorithm inside the instrument and the target emissivity.

Calibration of the forehead thermometer

Ambient temperature: Place the sensor in a 25.00 +/- 0.02 degree water tank, wait for it to stabilize and then press a key to confirm, which usually takes 30 seconds.

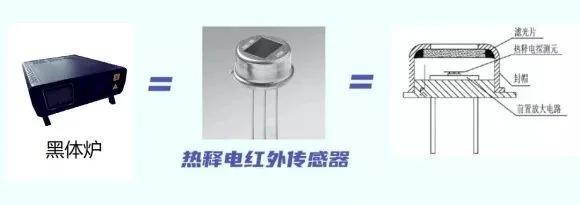

Blackbody temperature: first adjust the blackbody furnace to 37.00 +/- 0.02 degrees, then insert the sensor into the blackbody furnace, and press a key to confirm after it stabilizes. It usually takes 20 seconds.

What do you need to prepare for solution design and product production?

1. How many function keys does the shell have and what are their functions?

2. How many feet does the LCD screen need?

3. Is the sensor digital or analog?

4. Product specifications: what kind of battery is used, for home or medical use, and whether calibration is required

Production test requirements

2. Does the factory have a constant temperature room? Can it be adjusted to medium, high and low temperatures?

3. Do you know how to fix the heat sink? If there is a problem with one of the structure, optical components or sensors, it will lead to continuous testing and correction, which is also an unclear factor. Electronic design engineers may not be able to solve these problems.

4. Do you have clinical trial resources? (Find a hospital that has large, medium and small hospitals, with people with and without fever, and collect test data for a period of time)

5. If you are doing medical regulation, do you have domestic CFDA medical qualification? Abroad, it is called FDA and CE Medical (CFDA takes at least one and a half years to approve).

Design of infrared forehead thermometer

Solution Overview

The non-contact infrared forehead thermometer is a new instrument that uses modern sensor measurement technology, microelectronics technology and other technical means to measure the temperature of the object being measured. When the infrared forehead thermometer is aimed at and close to the object being measured to the effective distance detected by the digital proximity sensor, press the power/measurement button and hold it for several seconds, then the infrared sensor module inside the infrared forehead thermometer will collect the temperature and convert it into an electrical signal, then convert the electrical signal into a digital signal, and then transmit it to the single-chip microcomputer through the communication interface. The single-chip microcomputer collects the current ambient temperature through the digital temperature sensor, performs corresponding temperature compensation processing on the transmitted temperature digital signal, and stores the corrected temperature as the current record number. At the same time, it determines the LCD backlight range of the temperature, and then displays the corresponding backlight: (35.0-37.4℃) normal body temperature green backlight, (37.5-37.9℃) high body temperature yellow backlight, (38-42.9℃) high body temperature red backlight, if the body temperature is abnormal, it will also issue a "beep beep beep" alarm, and finally voice broadcast the current temperature. When not in use for more than 30 seconds, it automatically enters low power mode to save power.

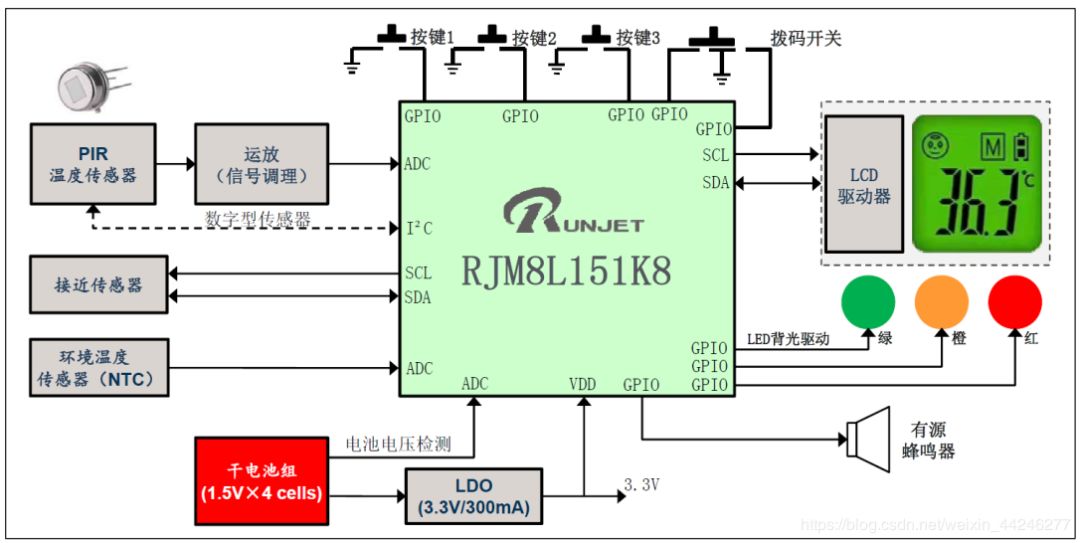

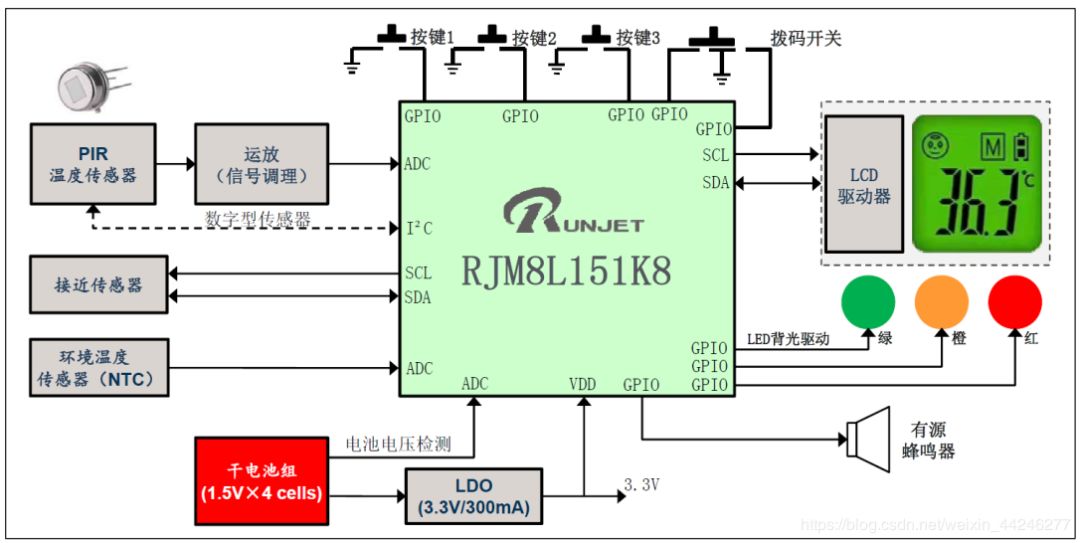

Solution Hardware Diagram

This non-contact infrared forehead thermometer solution consists of an ultra-low power, high-security MCU: RJM8L151, a power module, a button module, an infrared sensor module, a temperature sensor (module), a digital proximity sensor module, an ambient temperature sensor, a voice module, a speaker and an LCD display module. The hardware block diagram is shown below:

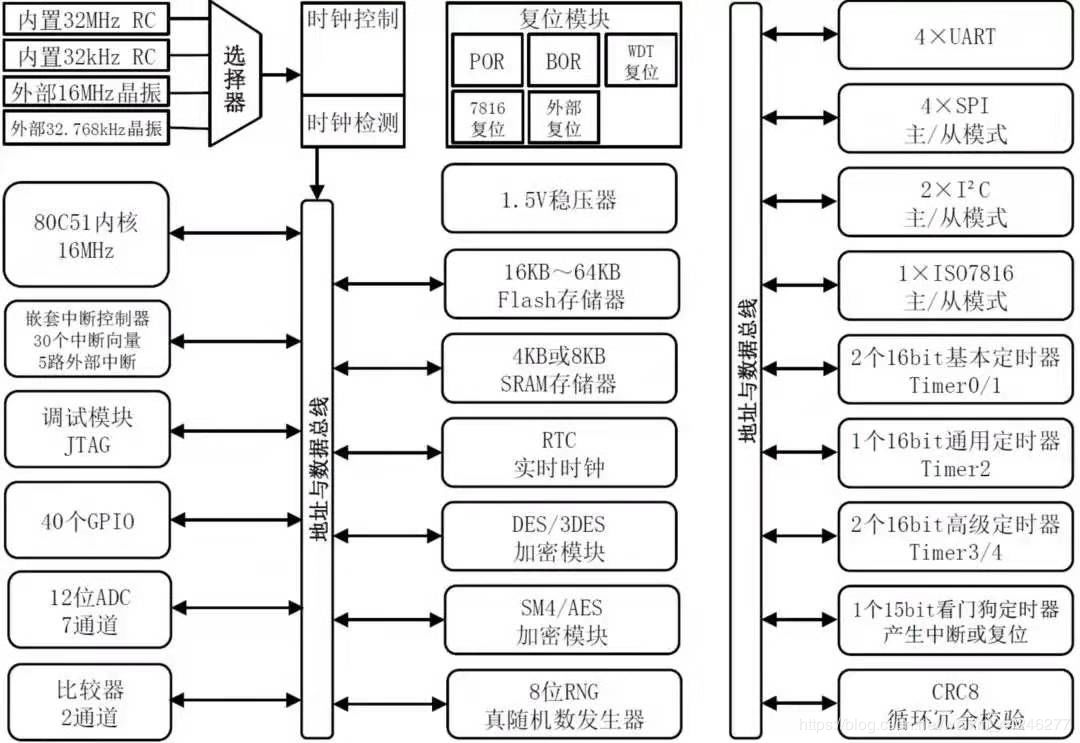

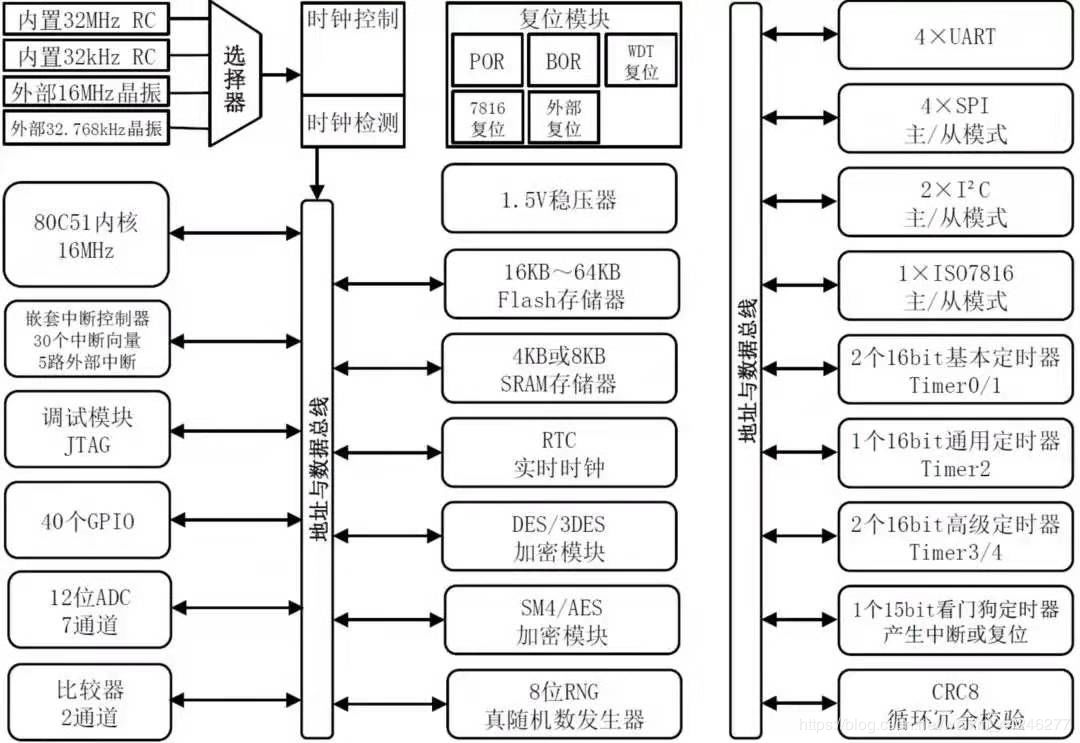

1. Microcontroller MCU

The ultra-low power and high-security RJM8L151 series MCU launched by Wuhan Ruinajie Electronic Technology Co., Ltd. is used. The chip has excellent running and standby power consumption performance, supports 4-way IO wake-up chip, and integrates 12-bit high-precision successive approximation ADC, 2-channel multi-function comparator, timer, real-time clock (RTC), watchdog timer (WDT), power supply programmable voltage detection (PVD), interrupt controller, hardware true random number generator, AES/DES/SM4 hardware encryption engine and communication interface: UATR, SPI, IIC, GPIO, ISO7816, JTAG and other modules, with high cost performance, large storage capacity, high security, low power consumption, rich interfaces and other characteristics. The chip supports the development and debugging of application code using KeiluVision or IAR integrated development environment. The hardware block diagram of the RJM8L151 series security MCU is shown in the figure below:

2. Power module

It is powered by 2 AAA dry batteries and uses a voltage conversion chip to maintain the output voltage of the power module to ensure that the MCU, infrared sensor, digital proximity sensor, voice chip, LCD screen and other modules can work normally and stably when the battery voltage drops.

3. Sensor module

A) Use an integrated infrared sensing module, which includes an infrared thermopile sensor and a dedicated processing chip. The advantages are stable circuit, simple interface, and easy debugging, but the disadvantage is that the price is relatively high. Sensor signals can be selected from MLX90614, HMS K1C1 F5.5, and 10TP583T, among which the following are examples:

The infrared sensing part of the infrared sensor MLX90614 is the 81101 thermoelectric unit. The 81101 is an infrared thermopile sensor, which receives the infrared radiation signal of the target object, and then amplifies and processes the signal through the internal DSP signal processing dedicated integrated chip MLX90302 and 17-bit ADC, and outputs it in PWM or SMBus mode (compatible with standard speed IIC). The measurement accuracy can reach 0.2%, the measurement speed is fast, and the low power consumption MLX90614 supports sleep mode. The digital temperature sensor is mainly used to measure the ambient temperature so that the infrared sensor can be used for temperature compensation to improve the accuracy. The digital proximity sensor is used to detect the effective distance when measuring temperature.

B) The use of thermopile sensor + peripheral circuit has the advantage of low cost, but the disadvantage is that the small signal amplification and processing circuit and temperature compensation circuit need to be carefully designed and debugged, and the product design cycle is long. Sensor signals can be selected from MTP10-B7F55, RTP678, etc., among which the following are examples:

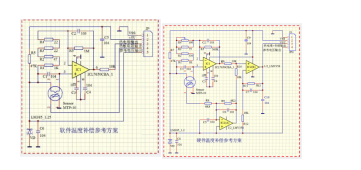

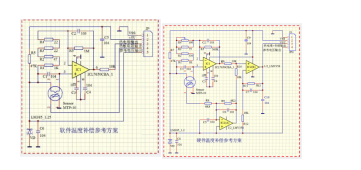

Using Sannic's MTP10-B7F55, fast and high-precision temperature measurement can be achieved. Its built-in NTC can measure the ambient temperature for temperature compensation to improve accuracy. Its application method can be flexibly selected. The principle is as follows:

(a) Software temperature compensation (b) Hardware temperature compensation

(c) Analog interface (d) Digital interface

3.2 Digital Proximity Sensor

It is used to determine the distance between the measured object and the PIR sensor. The measurement is started only when the object distance ratio is optimal, ensuring the accuracy of the measurement data, such as TMD26721.

3.3 Ambient temperature sensor

Its function is to obtain the ambient temperature during measurement, so as to remove the ambient temperature from the measured value of the infrared temperature sensor, obtain the measured human body temperature, and compensate the infrared temperature sensor. Some ambient temperature sensors are integrated into thermopile sensors, such as MTP10-B7F55.

4. Button module

The design includes 5 independent buttons, namely power/measurement button, SET button, UP button, DOWN button, and MODE button. The first 4 buttons have sleep and wake-up functions.

Power/Measurement Button: After pressing the button to wake up from sleep mode, the MCU will perform a temperature measurement and display the current temperature after completion.

SET button: After pressing the button to wake up from sleep mode, enter the function setting mode. Each press corresponds to the following functions:

F1 Display unit switch: Default is °C, press UP key to switch to °F, press DOWM key to switch to °C

F2 Voice broadcast switch ON/OFF: ON by default, press the UP key to switch to ON, press the DOWM key to switch to OFF

F3 Delete temperature record

UP key: Scroll up from the current temperature record to temperature record 32, and then scroll again to temperature record 1

DOWN key: scroll down from the current temperature record to temperature record 1, and scroll again to temperature record 32

MODE button: switch between human body mode and surface mode

5. Voice module

The voice chip WTN1010/VC505 is used to store voice fragments, such as 'ten o'clock', '℃', '℉', 'one', 'two', 'nine', 'beep beep beep', etc., and the complete voice is formed by playing the selected segments and putting them together to drive the speaker to sound.

6. LCD display module

Use RFD-TA20001ZT-11 to display current temperature, current memory temperature, measurement mode, battery status, voice switch status, etc.

Solution Function Specifications

2) Measurement distance: 3~8CM

3) Measurement mode: Human body mode: 32.0-42.9°C (89.6-109.3°F)

Body surface mode: 0.0-99.9°C (32.0-211.9°F)

4) Measurement time: <6s

5) Measurement accuracy: ±0.2°C (35.0°-42.0°C); ±0.3°C (other ranges)

6) Display resolution: 0.1°C or 0.1°F

7) Display unit: °C (Celsius) and °F (Fahrenheit)

8) Support 32 groups of storage memory

9) Support three-color backlight display

Normal body temperature: green backlight (35.0-37.4℃)

Yellow backlight when body temperature is high (37.5-37.9℃)

Red backlight for extremely high body temperature (38-42.9℃)

10) Support low battery voltage display

11)Support voice broadcast

12) Support automatic shutdown to save power

Advantages of RJM8L151:

1) Ultra-low power consumption

Up to 6 low-power management modes are available, including deep sleep power consumption of 5nA, external wake-up of less than 5us and support for 4-way IO wake-up, Halt mode power consumption as low as 0.4uA and RAM data retention, etc., which can greatly extend the battery life.

2) Built-in PVD programmable voltage detection

The input voltage after battery boosting can be quickly detected and managed in stages.

3) Built-in 12-bit high-precision successive approximation ADC

The battery voltage can be directly collected in real time and accurately to digitally display and understand the battery usage status.

4) Rich communication interfaces

The chip supports UATR, SPI, IIC, GPIO, ISO7816, etc. For extended functions, peripheral devices can have more communication options.

5) 15-bit watchdog timer

There is a built-in 15-bit watchdog timer, which can be used to reset the system when it runs abnormally or freezes, returning the system to normal operation, further improving the stability of the system.

6) Memory Security

High-strength physical protection circuits are designed for internal Flash, SRAM and other storage units to effectively prevent malicious code theft and reverse analysis.

Copyright Statement: This plan is an original article by CSDN blogger "1028_Yang Yang" and complies with the CC 4.0 BY-SA copyright agreement. Please attach the original source link and this statement when reprinting.

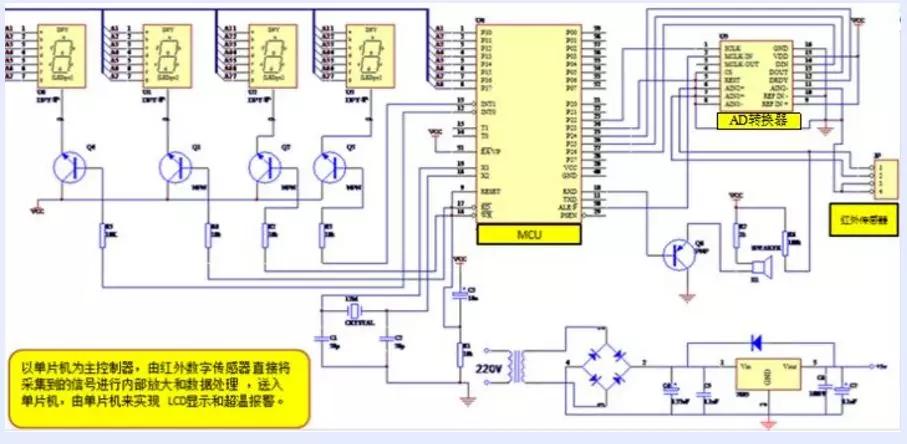

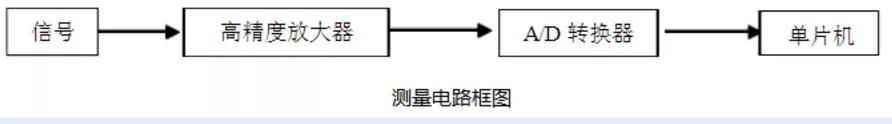

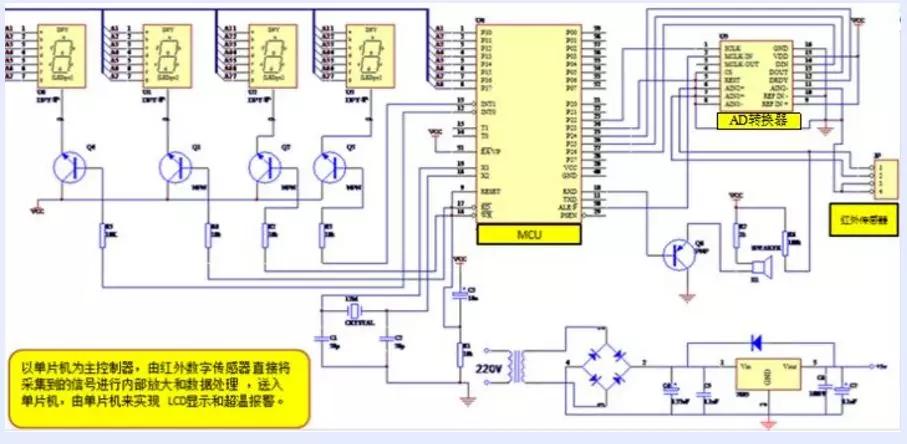

Ear Thermometer Digital Circuit Technology

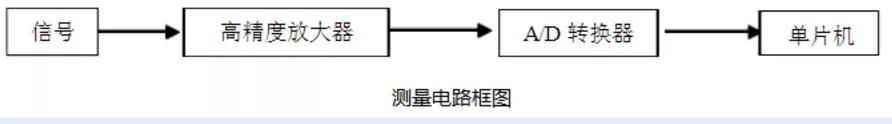

The principle of digital processing is to convert the signals of thermistors and thermopiles into electrical signals and amplify them. Through A/D conversion, the microcontroller collects the data and processes them internally to obtain the corresponding temperature value.

Complete circuit system

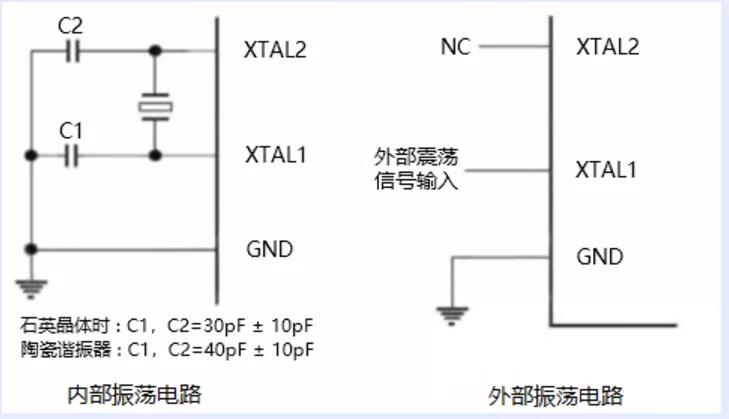

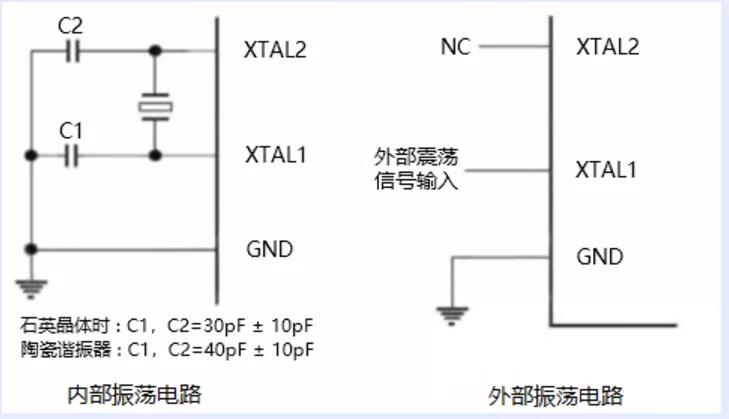

2. Clock circuit

3. Reset circuit

Reprinted from: https://mp.weixin.qq.com/s/G5uSegQ9mfAROwXC-Pwojw

|

提升卡

提升卡 变色卡

变色卡 千斤顶

千斤顶