Abstract: In view of the current situation that traditional car door locks are not safe and reliable enough, a simulated car fingerprint recognition door lock system based on fingerprint recognition technology is proposed. The overall scheme of the system is designed, and the relevant hardware is selected; the Biokey SDK algorithm is used as the software of the system, and the algorithm is secondary developed to meet the control requirements of the system. A simulated car fingerprint recognition door lock system is built. The output signal is measured and the action of the actuator is observed. The experiment shows that the system can control the car door lock switch well and is convenient and reliable.

0 Introduction

Car door locks are divided into two categories: mechanical and electronic. The biggest flaw of mechanical car door locks is the lack of security; the emergence of electronic car door locks has greatly improved the security of car door locks. However, with the development of technology, various special car theft tools and methods have been circulated on the Internet, and the security of electronic car door locks has been severely tested. Fingerprint recognition technology is one of the safest and most reliable identity recognition technologies at present. It has high feasibility and practicality, and is also the most mature and promising biometric technology.

This paper uses fingerprint recognition technology to design a simulated car fingerprint recognition door lock. According to the special situation of the car, the actuator is designed and the corresponding hardware is selected; secondary development is carried out based on the Biokey SDK algorithm to improve the software function. A simulated car fingerprint recognition door lock system is built to test whether the action of the actuator meets the requirements.

1 System overall design

The system can be divided into three parts: an automatic fingerprint recognition system consisting of a fingerprint collection device and a computer, a control system consisting of a computer and control elements, and a door lock controller and a bidirectional DC motor to simulate a car door lock (as shown in Figure 1).

1.1 Fingerprint collector

Fingerprint collection is the first step in the automatic fingerprint recognition system. Fingerprint collectors are usually classified according to the imaging method. Commonly used fingerprint imaging methods include: optical device imaging; crystal sensor imaging; ultrasonic device imaging. Ultrasonic scanning is considered to be a very good type of fingerprint imaging technology [1]. The author compared various fingerprint collectors on the market and selected the most cost-effective U.are.U4000 fingerprint collector. Its features include: automatic reading of fingerprint images, transferring digitized fingerprint images to computers via USB interface, and supporting Zhongkong Technology Biokey SDK development tools [2].

1.2 Data Acquisition Card

This system uses the PCI9111DG data acquisition card produced by Taiwan ADLink Company to realize the data input and output functions. The acquisition card has three data ports for communicating with the outside world: CN1, CN2, and CN3. This system only uses the CN3 port. ACLD-9137 is the wiring terminal for CN3. The author uses the analog output channel (port 30) and the analog ground port (port 9) on the wiring terminal to connect to the corresponding signal input port on the door lock controller to realize the control of the actuator.

1.3 Car door locks

The car door lock is composed of a door lock controller and an actuator. This system uses the bidirectional DC motor of the ALTO central door lock as the actuator, and simulates the door lock's opening and closing action by controlling the motor's forward and reverse rotation.

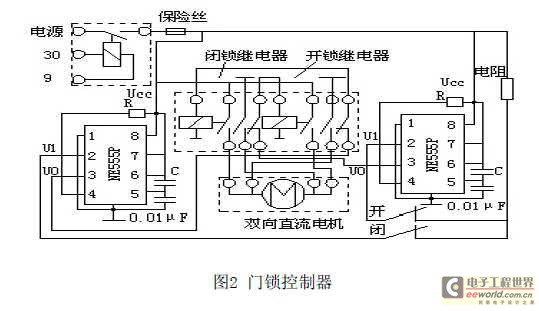

The function of the door lock controller is to control the switch of the door lock actuator, shorten the working time and save energy [3]. This system uses a door lock controller composed of a relay and a 555 monostable trigger to control the actuator. The circuit diagram of the door lock controller is shown in Figure 2.

Working principle of door lock controller: the door lock open and close button remains in the state, and the controller does not output the execution signal to the actuator; press the unlock button, the actuator rotates forward, and when the duration of pressing the button T>TP (the width of the rectangular pulse signal of the 555 monostable trigger output driving the relay), the actuator working time is equal to TP; the locking process is the same as the unlocking process; when the unlock and lock switches are pressed at the same time, due to the interlocking function between the relays, the door lock controller does not output a signal to the actuator to protect the circuit.

Pulse width calculation formula:

TP = RC ln 3 =1.1RC

Where R and C are the external resistance and capacitance of the 555 monostable trigger respectively[4].

2 Software Design

2.1 Biokey SDK Algorithm Description

The Biokey SDK algorithm is a fast and accurate 1:1 and 1:N fingerprint recognition algorithm that is fully open to software developers and system integrators. When using the Biokey SDK for fingerprint recognition (recognition of 2000 to 6000 fingerprints), it can be easily completed in 1 to 5 seconds without pre-classifying the fingerprints by name, PIN, etc. [5]. The standard process of the fingerprint recognition algorithm is shown in Figure 3:

[page]

2.2 Software interface functions and implementation

Secondary development of Biokey algorithm. Fingerprint registration is implemented by function OnOnEnrollZkfpengx2(). During the registration process, all fingerprints are stored in the computer memory according to the process number. Image saving is implemented by function: OnMeuSaveb and function OnMeusavej. The saving path can be set according to the actual situation. The two recognition forms of 1:1 and 1:N are implemented by: OnMeuOnetoone() and OnMeuOneton() respectively. After the match is successful, the signal is output by function m_PCI9111.WriteDOPort(). The variable temp in the function represents the voltage of the output signal. The author sets temp=6, that is, the output voltage is set to 6V.

The fingerprint recognition system flow chart is shown in Figure 4.

3 System Testing

Preparation: First, connect the pin jumper JP1 on PCI9111DG to U1 (the output signal range needs to be 0V~10V). Then start the software, register 5 different fingers and save the image, exit the software and re-enter. Then power on the door lock controller, select 1:N recognition type on the software interface, and test the system with different fingers. Use the multimeter voltage range to measure the voltage signals of terminals 30 and 9 on the ACLD-9137 line terminal, and observe the action of the bidirectional DC motor at the same time. 0 represents hold, 1 represents unlocking action, and -1 represents locking action. The system test results are shown in Table 1:

4 Conclusion

This system uses an optical fingerprint acquisition instrument to collect fingerprint images, uses a computer to calculate fingerprint images, and designs a simple and practical door lock controller to effectively control the door lock actuator, reducing the cost of the system. The test results show that the car fingerprint recognition door lock solution designed in this paper is feasible. It can effectively and conveniently control the opening and closing of the door lock, and the fingerprint recognition system makes the door lock have sufficient security.

The author's innovation: This paper proposes to apply fingerprint recognition technology to car door locks to solve the problem of insufficient security and reliability of traditional car door locks, laying a foundation for the application of fingerprint recognition technology in car anti-theft systems.

References

[1] Zhao Liang, Gong Mingmin. Research on identity authentication technology based on fingerprint recognition [J]. Microcomputer Information, 2006, 9-1: 301-304

[2] ZKT URU4000B fingerprint collector. http://www.yktchina.com/biz/2008_11/200811271250040713.html

[3] Liu Xigong. Central door lock system [M]. Practical manual for troubleshooting of domestic automobile central control/remote control door lock and anti-theft system. Beijing: Machinery Industry Press, 2008: 2-3

[4] Qin Zenghuang. Triggers and Sequential Logic Circuits[M]. Electrical Engineering. Beijing: Higher Education Press, 2008: 321-322.

[5] Guan Haixin. Member management system based on fingerprint recognition [D]. [Master's degree thesis], Sichuan: Sichuan University, 2006

[6] Guo Chuanjun. Research on computer fingerprint recognition technology [J]. China Science and Technology Information, 2007 (5): 108-109

Previous article:3S3P Automotive Tail Light (RCL) LED Driver Reference Design

Next article:Automotive body electronic control system solution based on 16-bit controller

- Popular Resources

- Popular amplifiers

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- MSP430F149 Learning Road - Capture/Compare Mode

- [Mil MYC-J1028X development board trial] Build a super powerful OpenWRT soft router

- Codebook Background Modeling

- It's Friday. Let's do a little reasoning

- Why should rectifier filter capacitors use high frequency and low resistance?

- Counting TI's star products in T-BOX: linear regulators | Section 5: TPS7B7701-Q1: Safeguarding automotive applications

- GD32E230C development board download error

- About the steps of converting .brd to .PCB

- In the LLC circuit, when the operating frequency fs is less than the resonant frequency fr, there is a problem with the secondary rectifier diode voltage waveform.

- bq40z50 series thermistor resistance coefficient calculator

Design of automotive BCM based on MC9S12XS128

Design of automotive BCM based on MC9S12XS128 Biokey_SDK Program Development Manual

Biokey_SDK Program Development Manual MN347H/BCH

MN347H/BCH

京公网安备 11010802033920号

京公网安备 11010802033920号