Preface

Since brushless DC motors have a series of advantages of AC motors such as simple structure, reliable operation, and easy maintenance, as well as many advantages of DC motors such as high operating efficiency, no excitation loss, and good speed regulation performance, they are becoming increasingly popular in various fields of today's national economy.

For more than a century, electric motors, as electromechanical energy conversion devices, have been used in all areas of the national economy and in people's daily lives. The main types are synchronous motors, asynchronous motors and DC motors. Since traditional DC motors use brushes for mechanical commutation, there is relative mechanical friction, which brings about weaknesses such as noise, fire, radio interference and short life. In addition, the high manufacturing cost and difficult maintenance have greatly limited its application range, resulting in the use of three-phase asynchronous motors in most industrial and agricultural production.

In view of the above shortcomings of traditional DC motors, as early as the 1930s, people began to develop DC brushless motors that use electronic commutation instead of brush mechanical commutation. After decades of efforts, this wish was finally realized in the early 1960s. Since the 1970s, with the rapid development of the power electronics industry, many high-performance semiconductor power devices, such as GTR, MOSFET, IGBT, IPM, etc., have appeared one after another, and the advent of high-performance permanent magnet materials have laid a solid foundation for the widespread application of DC brushless motors.

The basic composition of three-phase DC brushless motors

The DC brushless permanent magnet motor is mainly composed of three parts: the motor body, the position sensor and the electronic switch circuit. Its stator winding is generally made into multi-phase (three-phase, four-phase, five-phase, etc.), and the rotor is composed of permanent magnets with a certain number of pole pairs (2p=2,4,...). Figure 1 shows the structure of a three-phase two-pole DC brushless motor.

Figure 1 Composition of three-phase two-pole brushless DC motor

The three-phase stator windings are connected to the corresponding power switch devices in the electronic switch circuit respectively, and the A, B, and C phase windings are connected to the power switch tubes V1, V2, and V3 respectively. The tracking rotor of the position sensor is connected to the motor shaft.

When one phase of the stator winding is energized, the current interacts with the magnetic field generated by the magnetic poles of the rotor permanent magnet to generate torque, driving the rotor to rotate. The position sensor then converts the rotor magnet position into an electrical signal to control the electronic switch circuit, so that the stator windings are turned on in a certain order, and the stator phase current changes phase in a certain order as the rotor position changes. Since the conduction order of the electronic switch circuit is synchronized with the rotor angle, it plays the commutation role of the mechanical commutator.

Figure 2 is a schematic diagram of the semi-controlled bridge circuit of a three-phase brushless DC motor. Here, a photoelectric device is used as a position sensor, and three power transistors V1, V2, and V3 form a power logic unit.

Figure 2 Three-phase DC brushless motor

The three photoelectric devices VP1, VP2 and VP3 are installed at 120 degrees apart and evenly distributed at one end of the motor. With the help of the rotating shading plate installed on the motor shaft, the light from the light source is irradiated on each photoelectric device at once, and the position of the rotor magnetic pole is determined according to whether a photoelectric device is irradiated with light.

Figure 3 Switching sequence and schematic diagram of stator magnetic field rotation

The rotor position shown in Figure 2 corresponds to the position shown in Figure 3 a). Since the radio and television device VP1 is illuminated by light at this time, the power transistor V1 is turned on, and the current flows into the winding A-A'. The torque generated by the winding current and the rotor magnetic pole causes the rotor magnetic pole to rotate in the direction of the arrow in Figure 3. When the rotor magnetic pole rotates to the position shown in Figure 3 b), the rotating shading plate directly mounted on the rotor shaft also rotates synchronously, shielding VP1 and irradiating VP2 with light, so that transistor V1 is turned off and transistor V2 is turned on. The current is disconnected from winding A-A' and flows into winding B-B', so that the rotor magnetic pole continues to rotate in the direction of the arrow. When the rotor magnetic pole rotates to the position shown in Figure 3 c), the rotating shading plate has shielded VP2, so that VP3 is illuminated by light, causing transistor V2 to be turned off and transistor V3 to be turned on, so that the current flows into winding C-C', thereby driving the rotor magnetic pole to continue to rotate clockwise and return to the position of Figure 3 a).

In this way, as the position sensor rotor sector rotates, the stator winding is fed phase by phase under the control of the position sensors VP1, VP2, and VP3, realizing the phase change of the current of each phase winding. During the phase change process, the rotating magnetic field formed by each phase winding of the stator in the working air gap is jumpy. This rotating magnetic field has three magnetic states within the range of 360 electrical degrees, and each magnetic state lasts for 120 electrical degrees. The relationship between the current of each phase winding and the magnetic field of the motor rotor is shown in Figure 3. Figure 3a) is the first state, and Fa is the magnetomotive force generated after the winding A-A' is energized. Obviously, the interaction between the winding current and the rotor magnetic field causes the rotor to rotate in the clockwise direction; after rotating 120 degrees electrical angle, it enters the second state, at which time the winding A-A' is powered off, and B-B' is powered on, that is, the magnetic field generated by the stator winding rotates 120 degrees, as shown in Figure 3 b), and the motor stator continues to rotate in the clockwise direction; after rotating another 120 degrees electrical angle, it enters the third state, at which time the winding B-B' is powered off, C-C' is powered on, and the magnetic field generated by the stator winding rotates another 120 degrees electrical angle, as shown in Figure 3 c); it continues to drive the rotor to rotate 120 degrees electrical angle in the clockwise direction and then returns to the initial state. Figure 4 shows a schematic diagram of the conduction sequence of each phase winding.

Figure 4 Schematic diagram of conduction of each phase winding

Position sensor

The position sensor plays the role of determining the position of the rotor pole in the DC brushless motor and providing the correct commutation information for the logic switch circuit, that is, converting the position signal of the rotor magnetic pole into an electrical signal, and then controlling the commutation of the stator winding. There are many types of position sensors, each with its own characteristics. Common position sensors in DC brushless motors are as follows: electromagnetic position sensor, photoelectric position sensor, and magnetic position proximity sensor. The

electromagnetic position sensor is more commonly used in DC brushless motors. The open transformer used for three-phase DC brushless motors consists of two parts: the stator and the tracking rotor. The stator generally has six poles, and the intervals between them are 60 degrees. Three of the poles are wound with a primary winding, and are connected in series with each other and passed through a high-frequency power supply. The other three poles are wound with secondary windings WA, WB, and WC. They are 120 degrees apart. The tracking rotor is a cylinder made of non-magnetic material, and a 120-degree fan-shaped magnetic material is embedded on it. It is connected to the motor shaft during installation, and its position corresponds to a certain magnetic pole. The high-frequency magnetic flux generated by the primary winding is coupled to the secondary winding by tracking the material on the rotor, so an induced voltage is generated on the secondary winding, while the other two-phase secondary windings are connected to the primary winding without a coupling loop, so their induced voltage is basically zero. As the motor rotor rotates, the sector piece also rotates, causing it to leave the current coupled primary winding and approach the next primary winding. In this way, as the motor rotor moves, voltages are induced on the secondary windings of the open transformer. The angle of the sector-shaped magnetic conductive sheet is generally slightly larger than 120 degrees electrical angle, and is usually around 130 degrees electrical angle. In the three-phase full-control circuit, in order to meet the needs of the phase-changing decoder, the angle of the sector-shaped magnetic conductive sheet is 180 degrees electrical angle. At the same time, the number of sector-shaped magnetic conductive sheets should be equal to the number of pole pairs of the DC brushless motor.

The proximity switch position sensor is mainly composed of a resonant circuit and a fan-shaped metal rotor. When the fan-shaped metal rotor approaches the inductance L of the oscillation loop, the Q value of the circuit decreases, resulting in insufficient positive feedback and cessation of oscillation, so the output is zero. When the fan-shaped metal rotor leaves the inductance element L, the Q value of the circuit begins to rise, and the circuit starts to oscillate again, outputting a high-frequency modulation signal. After diode detection, the useful control signal is taken out to control the logic switch circuit to ensure the correct commutation of the motor.

As mentioned earlier, the photoelectric position sensor is made using the photoelectric effect. It consists of a shading plate that rotates with the motor rotor, a fixed light source, and a photoelectric tube.

A magnetic position sensor refers to a semiconductor sensitive element whose certain electrical parameters change with the surrounding magnetic field according to a certain law. Its basic principles are the Hall effect and the magnetoresistance effect. Common magnetic sensors include Hall elements or Hall integrated circuits, magnetoresistors, and magnetoresistive diodes.

The research results show that the Hall electromotive force E generated on the semiconductor wafer can be expressed by the following formula:

![]()

![]()

In the formula, RH is the Hall coefficient (

![]() );

);

IH is the control current (A);

B is the magnetic induction intensity (T);

d is the sheet thickness (m);

p is the material resistivity (Ω*s);

u is the material mobility (

![]() );

);

if the constants in the above formula are represented by KH, then

E=KHIHB.

The electromotive force generated by the Hall element is very low, and it is not convenient to apply it directly. Hall integrated circuits are used in practical applications. The polarity of the output voltage of the Hall element changes with the direction of the magnetic field. The position sensor of the DC brushless motor uses a switch-type Hall integrated circuit.

The magnetoresistance effect refers to the change of the resistance value of the element with the magnetic induction intensity. The sensor made according to the magnetoresistance effect is called a magnetoresistance resistor.

Operating characteristics of three-phase brushless DC motors

It is very difficult to analyze the operating characteristics of brushless DC motors very accurately. In general engineering applications, the following assumptions are made:

(1) The air gap magnetic induction intensity of the motor is distributed sinusoidally along the air gap.

(2) When the winding is energized, the effect of the magnetic flux generated by the current on the air gap is negligible.

(3) The control circuit works in the switching state, and the voltage drop of the power transistor is constant.

(4) Each winding is symmetrical, and its corresponding circuit is completely consistent, and the corresponding electrical time constant is negligible.

(5) The power consumption of the control circuit such as the position sensor is negligible.

Since it is assumed that the magnetic induction intensity generated by the rotor magnet is distributed sinusoidally in the air gap of the motor, that is, B=BMsinθ. In this way, if a continuous DC current is passed through a phase winding of the stator, the torque generated is

TM=ZDLBMrIsinθ

, where ZD is the number of effective conductors in each phase winding;

L is the effective length of the wire in the winding, that is, the length of the magnet;

r is the radius of the air gap in the motor;

I is the phase current of the winding.

That is to say, when a certain phase is connected with a constant DC, the torque generated by the interaction between it and the rotor magnetic field will also change according to the sinusoidal law with the different rotor positions, as shown in Figure 5.

Figure 5 Single-phase torque under constant current

For the external load, the average torque of the motor is zero. However, in the case of the three-phase half-controlled circuit of the DC brushless motor, a rectangular wave current of 1/3 cycle passes through each phase winding. The torque generated by the current and the rotor magnetic field is only a section of the sinusoidal torque curve equivalent to 1/3 cycle, and this section of the curve is related to the relative position of the rotor when the winding starts to be energized. Obviously, the maximum average torque can be generated by turning on the transistor at the moment shown in Figure 6a. Because in this case, the current-carrying conductor is in a relatively strong air gap magnetic field during the 120-degree time when the winding is energized. Therefore, the rotary pulse it generates is the smallest and the average value is larger. It is customary to select this point as the reference point for the transistor to start conducting and set it as. In the case of = 0 degrees, the total torque generated when the three-phase windings of the motor are energized in turn is shown in Figure 6b.

Figure 6 Half-bridge torque of three-phase brushless DC motor

If the conduction time of the transistor is advanced or delayed, the pulsation value of the torque will increase and the average value will decrease. When = 30 degrees, the instantaneous torque of the motor passes through the zero point, that is, when the rotor rotates to certain positions, the torque generated by the motor is zero, and a dead point will be generated when the motor starts. After ≥ 30 degrees, the instantaneous value of the motor torque will be negative, and the average value of the total output torque will be smaller. Therefore, in the case of three-phase half-control, especially at starting, it should not be greater than 30 degrees, and when the DC brushless motor is operating normally, always try to adjust the angle to 0 degrees to maximize the average torque generated by the motor. When = 0 degrees, the average value of the output torque can be obtained:

When the motor rotates under the action of electric torque, the rotating rotor magnetic field will cut the stator winding, inducing electromotive force on each phase winding. When its speed n remains unchanged, the electromotive force waveform is also a sine wave, and the phase is consistent with the torque phase. In this circuit, each phase winding is only energized in one cycle, so the applied voltage only works during this period. Therefore, for the applied voltage, the induced electromotive force waveform is shown in Figure 7.

Figure 7 Back electromotive force of a three-phase brushless DC motor semi-controlled circuit

Similarly, the average value of the induced electromotive force can be obtained by the following formula:

From the above average torque and average back electromotive force, the voltage balance equation of the DC brushless motor during stable operation can be obtained. To this end, the back electromotive force coefficient and torque coefficient are first defined:

For a specific motor, they are constants. Of course, their size depends on the connection method of the main circuit and the commutation method of the power transistor.

The voltage balance equations of the three-phase half-controlled bridge of the brushless DC motor are:

![]()

Among them,

![]() ,

,

![]() , after substituting them into the above formula, we can get its mechanical characteristic equation as follows:

, after substituting them into the above formula, we can get its mechanical characteristic equation as follows:

![]()

Where n is the motor speed (r/min);

U is the power supply voltage (V);

△U is the power tube voltage drop (V);

Kc is the electromotive force coefficient;

Ta is the average value of the electric torque generated by the motor (N?m);

KT is the torque coefficient;

R is the internal resistance of the motor (Ω).

In the three-phase half-controlled circuit, the torque fluctuation is between TM and TM/2, which is the disadvantage of the brushless DC motor.

Application of three-phase brushless DC motor

Three-phase half-controlled circuit

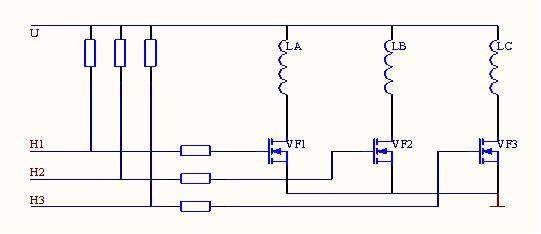

The common three-phase half-controlled circuit is shown in Figure 8. In the figure, LA, LB, and LC are the three-phase windings A, B, and C of the motor stator. VF1, VF2, and VF3 are three MOSFET power tubes, which mainly play the role of switches. H1, H2, and H3 are signals from the rotor position sensor. As mentioned above, in the three-phase half-controlled circuit, the output signal of the position sensor is required to be high level for 1/3 cycle and low level for 2/3 cycle, and the phase between each sensor signal is also required to be 1/3 cycle.

Figure 8 Three-phase half-controlled bridge circuit

Like general motors, when the motor starts, due to its low speed, the back electromotive force generated by the rotor flux cutting the stator winding is very small, so it may generate excessive current I. For this reason, an additional current limiting circuit is usually required. Figure 9 is a common one. The voltage comparator in the figure is mainly used to limit the main circuit current. When the voltage drop IRf of the current I passing through the motor winding on the anti-lock resistor Rf is greater than a given voltage U0, the comparator outputs a low level and turns off the three power field effect transistors VF1, VF2, and VF3 at the same time, that is, the main circuit is cut off. When IRf < U0, the comparator does not play any role. When IRf < U0, the comparator outputs a high level, and it does not play any role at this time. I0 = U0 / Rf is the maximum current to be limited, and its size depends on the specific requirements. Generally, it is about twice the rated current.

Figure 9 Limitation of starting current

Three-phase Y connection circuit

The three-phase half-controlled circuit has a simple structure, but the utilization rate of the motor body is very low. Each winding is only energized for 1/3 of the cycle, which is not fully utilized, and the torque fluctuates greatly during operation. In situations with higher requirements, the three-phase full-controlled circuit shown in Figure 10 is generally used. The three-phase full-controlled circuit has two types of commutation: two-two commutation and three-three commutation.

Figure 10 Three-phase full-control circuit

In this circuit, the three-phase winding of the motor is Y-connected. If the two-phase energization method is adopted, when the current is turned on from the power tubes VF1 and VF2, the current flows from VF1 into the A-phase winding, and then flows back to the power supply from the C-phase winding through VF2. If the torque generated by the current flowing into the winding is considered positive, then the torque generated from the winding is negative, and the magnitude of their combined torque is, and the direction is on the angle bisector of Ta and -Tc. After the motor rotates 60 degrees, VF1VF2 is energized and then VF2VF3 is energized. At this time, the current flows from VF3 into the B-phase winding, and then flows out from the C-phase winding through VF2 and returns to the power supply. At this time, the magnitude of the combined torque is also. But the direction of the combined torque T has rotated 60 degrees electrical angle. Then, each time a power tube is commutated, the direction of the combined torque vector rotates 60 degrees electrical angle. Therefore, the combined torque is increased by times by using the two-phase commutation method of the three-phase Y-connected full-control circuit. The phase is changed every 60 degrees of electrical angle, each power tube is energized for 120 degrees, each winding is energized for 240 degrees, and the forward and reverse directions are energized for 120 degrees respectively. The output torque waveform is shown in Figure 11. It can be seen from the figure that the torque fluctuation of the three-phase full control room is smaller than that of the three-phase half control room, from 0.87Tm to Tm.

Figure 11 Full-controlled bridge output waveform

Three-three power-on mode, the order of this power-on is VF1VF2VF3, VF2VF3VF4, VF3VF4VF5, VF4VF5VF6, VF5VF6VF1, VF6VF1VF2, VF1VF2VF3. When VF6VF1VF2 is turned on, the current flows from the VF1 tube into the A phase winding, and flows out from VF6 and VF2 through the B and C phase windings respectively. After 60 degrees of electrical angle, the phase is switched to VF1VF2VF3 for power-on. At this time, the current flows in from VF1 and VF3, flows into the C phase winding through the A and B phase windings, and flows out through VF2. In this power-on mode, three power tubes are powered at every moment. The phase is switched every 60 degrees, and one power tube is switched each time, and each power tube is powered for 180 degrees. The resultant torque is 1.5Ta.

The three-phase Δ connection circuit can also be divided into two control modes: two-by-two energization and three-by-three energization.

The power-on sequence of the two-by-two energization mode is VF1VF2, VF2VF3, VF3VF4, VF4VF5, VF5VF6, VF6VF1, VF1VF2. When VF1VF2 is turned on, the current flows in from VF1, passes through the A-phase winding and the B- and C-phase windings respectively, and then flows out from VF2. At this time, the connection of the windings is that the B- and C-phase windings are connected in series and then connected in parallel through the A-phase winding. If it is assumed that the current flowing through the A-phase winding is I, the current flowing through the B- and C-phase windings is I/2 respectively. The resultant torque here is 1.5 times the torque of the A-phase.

The order of the three-three power-on mode is VF1VF2VF3, VF2VF3VF4, VF3VF4VF5, VF4VF5VF6, VF5VF6VF1, VF6VF1VF2, VF1VF2VF3. When VF6VF1VF2 is powered on, the current flows in from the VF1 tube, passes through the A and B phase windings at the same time, and then flows out from the VF6 and VF2 tubes respectively. No current passes through the C phase winding, which is equivalent to the A and B phase windings being connected in parallel. At this time, it is equivalent to the A and B phase windings being connected in parallel, and the synthetic torque is times the torque of the A phase.

Microcomputer control of brushless DC motor

Figure 12 shows the principle block diagram of using 8751 single-chip microcomputer to control brushless DC motor. The P1 port of 8751 is connected with the 7406 inverter to control the commutation of the brushless DC motor. The P2 port is used to measure the signals H1, H2, and H3 from the position sensor. The P0 port is connected to an external digital-to-analog converter.

Figure 12 Schematic diagram of computer control of brushless DC motor

Commutation control

According to the commutation mode of the stator winding, first find out the state of the three rotor magnetic steel position sensor signals H1, H2, and H3, and the relationship between the six power tubes, and put them in the EEPROM of the microcontroller in a table form. 8751 can find the corresponding conductive power tube according to the state from H1, H2, and H3, and send it through the P1 port to realize the commutation of the brushless DC motor.

Starting current limitation

The resistor R13 is connected in series in the main circuit, so Uf=R13*IM, and its size is proportional to the motor current IM. Uf and the output voltage U0 of the digital-to-analog converter are respectively sent to the two input terminals of the LM324 operational amplifier. Once the feedback voltage is greater than Uf and greater than the given signal U0 from the digital-to-analog converter, the LM324 outputs a low level, so that the three power tubes VF4, VF6, and VF2 in the main circuit cannot be turned on, thereby cutting off all current paths of the stator winding of the DC brushless motor and forcing the motor current to drop. Once the current drops to make Uf less than U0, the LM324 output returns to a high level. The main circuit also has the ability to conduct, which plays a role in limiting the current.

Speed control

During the normal operation of the DC brushless motor, the current of the DC brushless motor can be controlled by controlling the output voltage U0 of the digital-to-analog converter, and then the current of the motor can be controlled. That is, the 8751 single-chip microcomputer calculates the speed of the motor through the period of the sensor signal and compares it with the given speed. If it is higher than the given speed, the output value of the P2 port is reduced, the motor current is reduced, and the purpose of reducing its speed is achieved. On the contrary, the output value of the P2 port is increased, thereby increasing the speed of the motor.

Implementation of PWM control

Speed control can also be achieved through PWM. Figures 13 and 14 show how PWM control is used to control the speed of a brushless DC motor.

Figure 13 PWM control principle diagram

Figure 14 PWM control principle diagram

The forward and reverse rotation of the DC brushless motor changes its rotation direction by changing the commutation order. The specific method only requires changing the commutation control table.

Implementation of variable structure control

When the DC brushless motor is in the starting state or in the adjustment process, the operation mode of the DC brushless motor is adopted to achieve the rapidity of dynamic response. Once the motor speed reaches the given value, it is immediately transferred to the synchronous motor operation mode to ensure its steady speed accuracy. At this time, the computer only needs to control the commutation of the motor at a certain frequency. At the same time, the computer measures the speed through the signal cycle of the position sensor and determines whether it falls out of synchronization. Once the cloth is lost, it will immediately switch to the operation of the DC brushless motor and pull it back into synchronization.

Figure 15 Variable structure control of brushless DC motor

Previous article:The structure principle and application of bidirectional thyristor

Next article:QTouch Technology

- Popular Resources

- Popular amplifiers

- Molex leverages SAP solutions to drive smart supply chain collaboration

- Pickering Launches New Future-Proof PXIe Single-Slot Controller for High-Performance Test and Measurement Applications

- CGD and Qorvo to jointly revolutionize motor control solutions

- Advanced gameplay, Harting takes your PCB board connection to a new level!

- Nidec Intelligent Motion is the first to launch an electric clutch ECU for two-wheeled vehicles

- Bosch and Tsinghua University renew cooperation agreement on artificial intelligence research to jointly promote the development of artificial intelligence in the industrial field

- GigaDevice unveils new MCU products, deeply unlocking industrial application scenarios with diversified products and solutions

- Advantech: Investing in Edge AI Innovation to Drive an Intelligent Future

- CGD and QORVO will revolutionize motor control solutions

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- FPGA Design Practice (Logic)

- SIMterix-Simplies~4~ Verilog

- 6. [Learning LPC1768 library functions] Watchdog experiment

- [AT32F421 Review] +PWM adjusts fan speed

- 【IOT harmful gas detection equipment based on STM32F7508-DK】Work submission

- Five Design Challenges Facing Remote Patient Monitoring Systems

- 【FAQ】ST wide bandgap high-performance silicon carbide and gallium nitride products and technologies and different application cases

- Answer the questions to win a gift | Choose gate drivers from Infineon, and get a 50-yuan JD card

- Share a table of the electrical and thermal characteristics of the selected packaging materials

- [RVB2601 Creative Application Development] Flower Watering Detector - Development Board Introduction

5962-9072301HXX

5962-9072301HXX

京公网安备 11010802033920号

京公网安备 11010802033920号