Introduction

The light emitting diode (LED) was invented in the 1960s. It uses the electrons and holes in semiconductor materials to combine and release energy, so that the energy band (Energy Gat) level changes, and emits light to show the energy released. LED has the advantages of small size, long life, low driving voltage, low power consumption, fast reaction rate, good shock resistance, etc., and is widely used in signal indication, digital display and other fields. With the continuous advancement of technology, the development of ultra-bright LED has been successful, especially the development of white light LED, which makes it more and more used in color lamp decoration and even lighting.

1. Characteristics of ultra-bright LED

Compared with traditional lighting lamps, ultra-bright LED has the following advantages:

1) Long life, reliable and durable, extremely low maintenance cost LED can be used continuously for 105h, 100 times longer than ordinary incandescent bulbs;

2) High efficiency can now reach 201m/w. It is expected to reach 501m/W by 2005[1]. The spectrum of LED is almost entirely concentrated in the visible light band, and its luminous efficiency can reach 80%~90%. LED can save 1/4 of energy compared with energy-saving lamps

. 3) Bright colors, simple light color. Take a 12-inch red traffic light as an example. It uses a low-efficiency 140W incandescent lamp as the light source. After the 2000lm white light passes through the red filter, the light loss is 90%, leaving only 2001lm of red light. In the lamp designed by Lumileds Lighting using 18 red LED light sources, including circuit losses, it only consumes 14W of power to produce the same light effect.

4) Fast lighting speed. Automobile signal lights are an important application area of LED light sources. Due to the fast response speed of LED (ns level), installing high-position LED brake lights on cars can reduce the occurrence of car rear-end collisions.

Although ultra-bright LEDs have many advantages, they still have the following disadvantages:

1) Low power. The power of single LEDs on the market is generally below 5W, and there are no higher power LEDs. This is the biggest bottleneck that makes it difficult for LEDs to become the first choice for lighting.

2) The need for strict temperature control. LED is a semiconductor material with a PN junction like ordinary diodes. Since the power of high-brightness diodes is relatively large, heat dissipation needs to be considered as with power semiconductor devices. Excessive junction temperature will directly affect the life of the LED and increase the light decay of the LED. In severe cases, the LED will burn out.

3) High price. In addition to low power, price is the main factor that makes it difficult for LEDs to become lighting. Although LEDs are now recognized and favored by most people, their high prices are difficult for consumers to accept.

2. Characteristics of ultra-bright LEDs

HPWA-xH00 is a Lumileds This article uses a super bright LED from Lighting Company as an example to analyze the characteristics of super bright LEDs. Figure 1 shows the relationship curve between forward voltage drop (VF) and forward current (IF). From the curve, it can be seen that when the forward voltage exceeds a certain threshold (about 2V), which is usually called the on-voltage, it can be approximately considered that IF is proportional to VF. Table 1 shows the electrical characteristics of the current main super bright LEDs. From Table 1, it can be seen that the current maximum IF of super bright LEDs can reach 1A, while VF is usually 3~4V.

Since the optical characteristics of LEDs are usually described as a function of current, rather than a function of voltage, The relationship curve between the number of luminous flux (φV) and IF is shown in Figure 2. Therefore, the constant current source drive can better control the brightness. In addition, it can be seen from Table 1 that the forward voltage drop of the LED has a relatively large range of variation (up to 1V or more), and from the VF-IF curve in Figure 1, it can be seen that a small change in VF will cause a large change in IF, thereby causing a large change in brightness. Therefore, the use of a constant voltage source drive cannot guarantee the consistency of the LED brightness, and affects the reliability, life and light decay of the LED. Therefore, ultra-bright LEDs are usually driven by a constant current source.

Figure 3 is HPWA-xH00 The relationship curve between LED temperature and luminous flux (φV) is shown in Figure 3. The luminous flux is inversely proportional to the temperature. The luminous flux at 85℃ is half of that at 25℃, and the light output at -40℃ is 1.8 times that at 25℃. The change in temperature also has a certain impact on the wavelength of LFD. Therefore, good heat dissipation is the guarantee for the LED to maintain constant brightness.

3 Driving circuit of ultra-bright LED

Due to the limitation of LED power level, it is usually necessary to drive multiple LEDs at the same time to meet the brightness requirements. Therefore, a special driving circuit is required to light up the LED. The main circuits of LED driving are briefly introduced below.

3.1 Resistor current limiting circuit

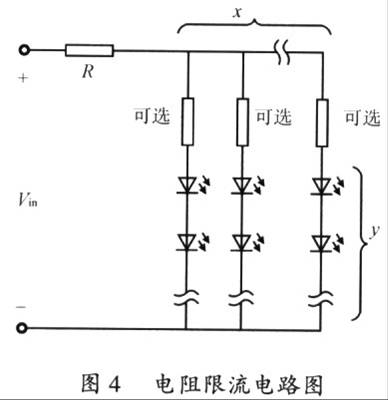

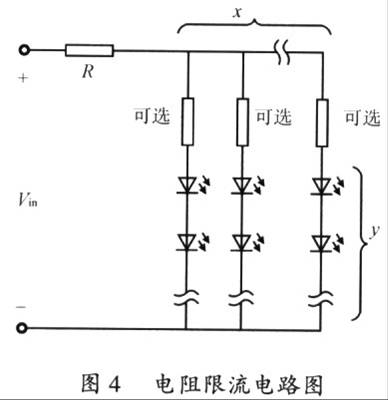

As shown in Figure 4, the resistor current limiting driving circuit is the simplest driving circuit. The current limiting resistor is calculated according to formula (1).

Where: Vin is the input voltage of the circuit:

VF is the forward current of IED;

VF is the voltage drop of LED when the forward current is IF;

VD is the voltage drop of the anti-reverse diode (optional);

y is the number of LEDs in each string;

x is the number of parallel LED strings.

From Figure 1, the linearized mathematical model of LED is:

Where: Vo is the turn-on voltage drop of a single LED;

Rs is the linearized equivalent series resistance of a single LED.

Then the calculation of the current limiting resistor in formula (1) can be written as:

When the resistor is selected, the relationship between IF and VF of the resistor current limiting circuit is:

From formula (4), it can be seen that the resistor current limiting circuit is simple, but when the input voltage fluctuates, the current through the LED will also change, so the regulation performance is poor. In addition, since the power loss of the resistor R is xRIF, the efficiency is low.

3.2 Linear regulator

The core of the linear regulator is to use the power transistor or MOSFET working in the linear region as a dynamically adjustable resistor to control the load. There are two types of linear regulators: parallel type and series type.

Figure 5 (a) shows a parallel linear regulator, also known as a shunt regulator (only one LED is drawn in the figure, but in fact the load can be multiple LEDs in series, the same below). It is connected in parallel with the LED. When the input voltage increases or the LED decreases, the current through the shunt regulator will increase, which will increase the voltage drop on the current limiting resistor to keep the current through the LED constant.

Since the shunt regulator needs a resistor in series, the efficiency is not high, and it is difficult to achieve constant regulation when the input voltage changes over a wide range.

Figure 5 (b) shows a series regulator. When the input voltage increases, the dynamic resistance is increased to keep the voltage (current) on the LED constant.

Since the power transistor or MOSFET has a saturation conduction voltage, the minimum input voltage must be greater than the sum of the saturation voltage and the load voltage for the circuit to work correctly.

3.3 Switching regulator The

above driving technology is not only limited by the input voltage range, but also has low efficiency. When used for low-power ordinary LED driving, the loss is not obvious because the current is only a few mA. When used for driving high-brightness LEDs with a current of several hundred mA or even higher, the loss of the power circuit becomes a more serious problem. The switching power supply is the most efficient in energy conversion at present, which can reach more than 90%. Power converters such as Buek, Boost and Buck-Boost can all be used to drive LEDs, but in order to meet the constant current drive of LEDs, the output current is detected instead of the output voltage for feedback control.

Figure 6 (a) is an LED driving circuit using a Buck converter. Unlike the traditional Buek converter, the switch tube S is moved behind the inductor L, so that the source of S is grounded, which facilitates the driving of S. The LED is connected in series with L, and the freewheeling diode D is connected in anti-parallel with the series circuit. The driving circuit is not only simple but also does not require an output filter capacitor, which reduces the cost. However, the Buck converter is a step-down converter and is not suitable for occasions with low input voltage or multiple LEDs connected in series.

Figure 6 (b) is an LED driving circuit using a Boost converter. The output voltage is pumped to a higher expected value than the input voltage through inductor energy storage, realizing the driving of the LED under low input voltage.

Figure 6 (c) is an LED driving circuit using a Buck-Boost converter. Similar to the Buek circuit, the source of S in this circuit can be directly grounded, which facilitates the driving of S. Although the Boost and Buck-Boosl converters have one more capacitor than the Buck converter, they can both increase the absolute value of the output voltage. Therefore, they are more widely used when the input voltage is low and multiple LEDs need to be driven

. Introduction to the driver control chip of ultra-bright LED

Based on the characteristics of high-power constant current drive of high-brightness LED, many companies have launched dedicated driver control chips for high-brightness LED, such as: MELexis, Infinton (Infineon), Lienear Technology (Linte), Supenex Inc, Analog.Devices (ADI), etc.

4.1 Introduction to MLxl0801 chip

MLXl0801 is a LED driver chip for automotive applications published by Melexi8. The chip can also be used to drive coils such as relays and as an electronic fuse. The principle block diagram of the MLxl0801 chip is shown in Figure 7. It integrates power MOSFET with a maximum drive current of 350mA. When used as an LED driver, it has the following characteristics:

- Simple external application circuit;

- Internal/external temperature detection protection;

- High-efficiency switching power supply drive;

- Brightness can be controlled by PWM input;

- LED parameters can be adjusted and stored in the on-chip NV memory.

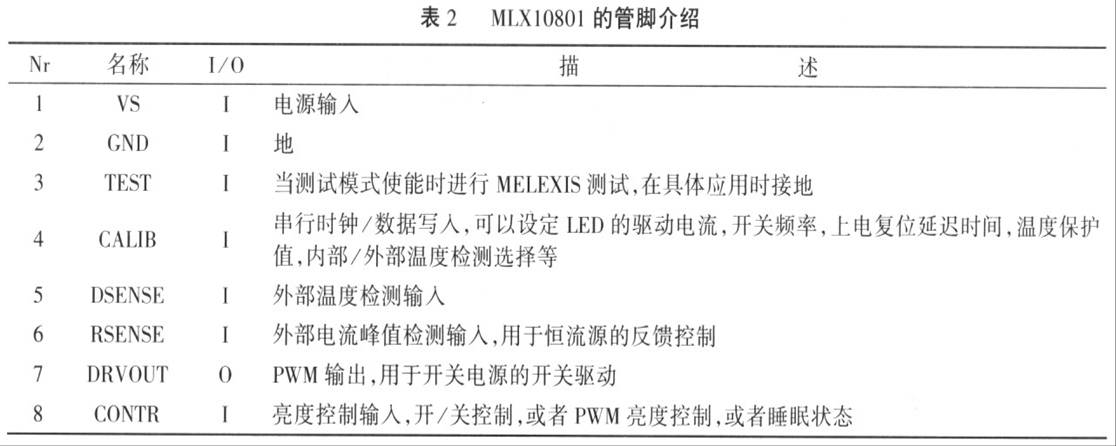

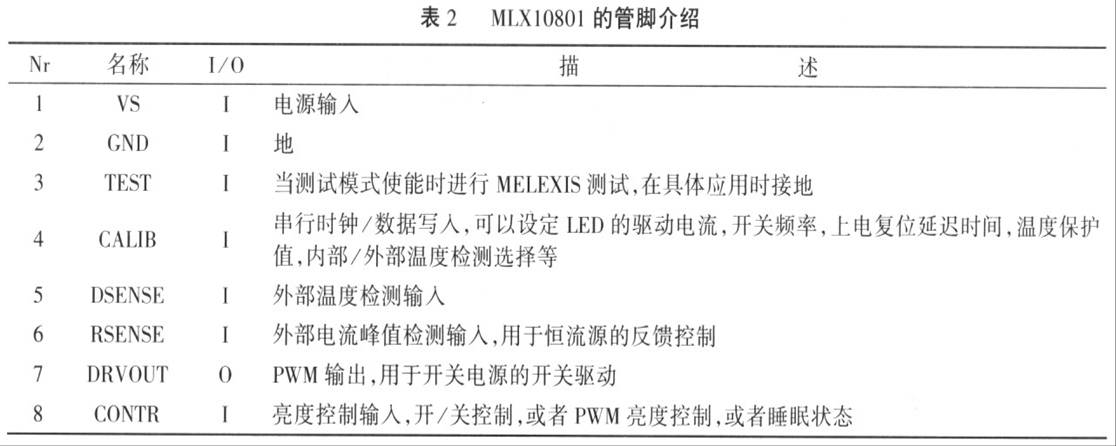

Although MLX10801 has only 8 pins, it is powerful. Table 2 is an introduction to the pin functions of MLX10801.

Figure 8 is a typical application circuit of MLX10801. LED, L, D2, Rsense and MOSFET integrated in MLX10801 form a typical Buck-type LED driver circuit. The LED in Figure 8 can be connected in series with multiple LEDs according to the brightness requirements. MLX10801 detects the peak current through the LED by detecting the voltage on Rsense, compares the current value with the set reference value, and controls the LED current by controlling the pulse width of the pin DRV0UT. CONTR can be used as an external switch. On/off control, or input PWM signal to control LED flashing. When control is not needed, this pin can be connected to pin VS through resistor R. DSENSE is used to connect an external thermistor to detect LED temperature and protect IED. Although the MLXl0801 chip has a built-in thermistor, in order to ensure that the temperature can be correctly detected when the chip is far away from the LED, MIX10801 still sets pin DSENSE to achieve long-distance temperature detection. Pin CALIB is used to communicate with the controller to receive parameters such as the controller setting LED current, maximum allowed temperature, internal temperature detection or external temperature detection, whether to prevent shaking, and soft start time.

4.2 Comparison of high-power LED driver chips

Table 3 lists the performance comparison of the current main high-power IED driver control chips. When using high-power IED driver control chips, you can choose according to different application scenarios:

1) When higher power is required, you can choose a controller that does not integrate the power device in the chip, so that you can choose the power device separately according to the actual power demand;

2) When higher conversion efficiency is required, such as portable devices, you can choose a switch power supply type drive circuit;

3) When used in high-reliability equipment, you can choose a chip with comprehensive control functions such as temperature protection and fault alarm.

5 Conclusion

With the advancement of technology, the power of ultra-bright LEDs will be further improved and the cost will be reduced. High-efficiency and energy-saving ultra-bright LEDs will be widely used in the lighting field. Low-cost, high-reliability drive circuits are the key to ensuring that LEDs have lasting brightness.

Keywords:LED

Reference address:Brief Analysis of the Driving Function and Application of Ultra-Bright LED

The light emitting diode (LED) was invented in the 1960s. It uses the electrons and holes in semiconductor materials to combine and release energy, so that the energy band (Energy Gat) level changes, and emits light to show the energy released. LED has the advantages of small size, long life, low driving voltage, low power consumption, fast reaction rate, good shock resistance, etc., and is widely used in signal indication, digital display and other fields. With the continuous advancement of technology, the development of ultra-bright LED has been successful, especially the development of white light LED, which makes it more and more used in color lamp decoration and even lighting.

1. Characteristics of ultra-bright LED

Compared with traditional lighting lamps, ultra-bright LED has the following advantages:

1) Long life, reliable and durable, extremely low maintenance cost LED can be used continuously for 105h, 100 times longer than ordinary incandescent bulbs;

2) High efficiency can now reach 201m/w. It is expected to reach 501m/W by 2005[1]. The spectrum of LED is almost entirely concentrated in the visible light band, and its luminous efficiency can reach 80%~90%. LED can save 1/4 of energy compared with energy-saving lamps

. 3) Bright colors, simple light color. Take a 12-inch red traffic light as an example. It uses a low-efficiency 140W incandescent lamp as the light source. After the 2000lm white light passes through the red filter, the light loss is 90%, leaving only 2001lm of red light. In the lamp designed by Lumileds Lighting using 18 red LED light sources, including circuit losses, it only consumes 14W of power to produce the same light effect.

4) Fast lighting speed. Automobile signal lights are an important application area of LED light sources. Due to the fast response speed of LED (ns level), installing high-position LED brake lights on cars can reduce the occurrence of car rear-end collisions.

Although ultra-bright LEDs have many advantages, they still have the following disadvantages:

1) Low power. The power of single LEDs on the market is generally below 5W, and there are no higher power LEDs. This is the biggest bottleneck that makes it difficult for LEDs to become the first choice for lighting.

2) The need for strict temperature control. LED is a semiconductor material with a PN junction like ordinary diodes. Since the power of high-brightness diodes is relatively large, heat dissipation needs to be considered as with power semiconductor devices. Excessive junction temperature will directly affect the life of the LED and increase the light decay of the LED. In severe cases, the LED will burn out.

3) High price. In addition to low power, price is the main factor that makes it difficult for LEDs to become lighting. Although LEDs are now recognized and favored by most people, their high prices are difficult for consumers to accept.

2. Characteristics of ultra-bright LEDs

HPWA-xH00 is a Lumileds This article uses a super bright LED from Lighting Company as an example to analyze the characteristics of super bright LEDs. Figure 1 shows the relationship curve between forward voltage drop (VF) and forward current (IF). From the curve, it can be seen that when the forward voltage exceeds a certain threshold (about 2V), which is usually called the on-voltage, it can be approximately considered that IF is proportional to VF. Table 1 shows the electrical characteristics of the current main super bright LEDs. From Table 1, it can be seen that the current maximum IF of super bright LEDs can reach 1A, while VF is usually 3~4V.

Since the optical characteristics of LEDs are usually described as a function of current, rather than a function of voltage, The relationship curve between the number of luminous flux (φV) and IF is shown in Figure 2. Therefore, the constant current source drive can better control the brightness. In addition, it can be seen from Table 1 that the forward voltage drop of the LED has a relatively large range of variation (up to 1V or more), and from the VF-IF curve in Figure 1, it can be seen that a small change in VF will cause a large change in IF, thereby causing a large change in brightness. Therefore, the use of a constant voltage source drive cannot guarantee the consistency of the LED brightness, and affects the reliability, life and light decay of the LED. Therefore, ultra-bright LEDs are usually driven by a constant current source.

Figure 3 is HPWA-xH00 The relationship curve between LED temperature and luminous flux (φV) is shown in Figure 3. The luminous flux is inversely proportional to the temperature. The luminous flux at 85℃ is half of that at 25℃, and the light output at -40℃ is 1.8 times that at 25℃. The change in temperature also has a certain impact on the wavelength of LFD. Therefore, good heat dissipation is the guarantee for the LED to maintain constant brightness.

3 Driving circuit of ultra-bright LED

Due to the limitation of LED power level, it is usually necessary to drive multiple LEDs at the same time to meet the brightness requirements. Therefore, a special driving circuit is required to light up the LED. The main circuits of LED driving are briefly introduced below.

3.1 Resistor current limiting circuit

As shown in Figure 4, the resistor current limiting driving circuit is the simplest driving circuit. The current limiting resistor is calculated according to formula (1).

Where: Vin is the input voltage of the circuit:

VF is the forward current of IED;

VF is the voltage drop of LED when the forward current is IF;

VD is the voltage drop of the anti-reverse diode (optional);

y is the number of LEDs in each string;

x is the number of parallel LED strings.

From Figure 1, the linearized mathematical model of LED is:

Where: Vo is the turn-on voltage drop of a single LED;

Rs is the linearized equivalent series resistance of a single LED.

Then the calculation of the current limiting resistor in formula (1) can be written as:

When the resistor is selected, the relationship between IF and VF of the resistor current limiting circuit is:

From formula (4), it can be seen that the resistor current limiting circuit is simple, but when the input voltage fluctuates, the current through the LED will also change, so the regulation performance is poor. In addition, since the power loss of the resistor R is xRIF, the efficiency is low.

3.2 Linear regulator

The core of the linear regulator is to use the power transistor or MOSFET working in the linear region as a dynamically adjustable resistor to control the load. There are two types of linear regulators: parallel type and series type.

Figure 5 (a) shows a parallel linear regulator, also known as a shunt regulator (only one LED is drawn in the figure, but in fact the load can be multiple LEDs in series, the same below). It is connected in parallel with the LED. When the input voltage increases or the LED decreases, the current through the shunt regulator will increase, which will increase the voltage drop on the current limiting resistor to keep the current through the LED constant.

Since the shunt regulator needs a resistor in series, the efficiency is not high, and it is difficult to achieve constant regulation when the input voltage changes over a wide range.

Figure 5 (b) shows a series regulator. When the input voltage increases, the dynamic resistance is increased to keep the voltage (current) on the LED constant.

Since the power transistor or MOSFET has a saturation conduction voltage, the minimum input voltage must be greater than the sum of the saturation voltage and the load voltage for the circuit to work correctly.

3.3 Switching regulator The

above driving technology is not only limited by the input voltage range, but also has low efficiency. When used for low-power ordinary LED driving, the loss is not obvious because the current is only a few mA. When used for driving high-brightness LEDs with a current of several hundred mA or even higher, the loss of the power circuit becomes a more serious problem. The switching power supply is the most efficient in energy conversion at present, which can reach more than 90%. Power converters such as Buek, Boost and Buck-Boost can all be used to drive LEDs, but in order to meet the constant current drive of LEDs, the output current is detected instead of the output voltage for feedback control.

Figure 6 (a) is an LED driving circuit using a Buck converter. Unlike the traditional Buek converter, the switch tube S is moved behind the inductor L, so that the source of S is grounded, which facilitates the driving of S. The LED is connected in series with L, and the freewheeling diode D is connected in anti-parallel with the series circuit. The driving circuit is not only simple but also does not require an output filter capacitor, which reduces the cost. However, the Buck converter is a step-down converter and is not suitable for occasions with low input voltage or multiple LEDs connected in series.

Figure 6 (b) is an LED driving circuit using a Boost converter. The output voltage is pumped to a higher expected value than the input voltage through inductor energy storage, realizing the driving of the LED under low input voltage.

Figure 6 (c) is an LED driving circuit using a Buck-Boost converter. Similar to the Buek circuit, the source of S in this circuit can be directly grounded, which facilitates the driving of S. Although the Boost and Buck-Boosl converters have one more capacitor than the Buck converter, they can both increase the absolute value of the output voltage. Therefore, they are more widely used when the input voltage is low and multiple LEDs need to be driven

. Introduction to the driver control chip of ultra-bright LED

Based on the characteristics of high-power constant current drive of high-brightness LED, many companies have launched dedicated driver control chips for high-brightness LED, such as: MELexis, Infinton (Infineon), Lienear Technology (Linte), Supenex Inc, Analog.Devices (ADI), etc.

4.1 Introduction to MLxl0801 chip

MLXl0801 is a LED driver chip for automotive applications published by Melexi8. The chip can also be used to drive coils such as relays and as an electronic fuse. The principle block diagram of the MLxl0801 chip is shown in Figure 7. It integrates power MOSFET with a maximum drive current of 350mA. When used as an LED driver, it has the following characteristics:

- Simple external application circuit;

- Internal/external temperature detection protection;

- High-efficiency switching power supply drive;

- Brightness can be controlled by PWM input;

- LED parameters can be adjusted and stored in the on-chip NV memory.

Although MLX10801 has only 8 pins, it is powerful. Table 2 is an introduction to the pin functions of MLX10801.

Figure 8 is a typical application circuit of MLX10801. LED, L, D2, Rsense and MOSFET integrated in MLX10801 form a typical Buck-type LED driver circuit. The LED in Figure 8 can be connected in series with multiple LEDs according to the brightness requirements. MLX10801 detects the peak current through the LED by detecting the voltage on Rsense, compares the current value with the set reference value, and controls the LED current by controlling the pulse width of the pin DRV0UT. CONTR can be used as an external switch. On/off control, or input PWM signal to control LED flashing. When control is not needed, this pin can be connected to pin VS through resistor R. DSENSE is used to connect an external thermistor to detect LED temperature and protect IED. Although the MLXl0801 chip has a built-in thermistor, in order to ensure that the temperature can be correctly detected when the chip is far away from the LED, MIX10801 still sets pin DSENSE to achieve long-distance temperature detection. Pin CALIB is used to communicate with the controller to receive parameters such as the controller setting LED current, maximum allowed temperature, internal temperature detection or external temperature detection, whether to prevent shaking, and soft start time.

4.2 Comparison of high-power LED driver chips

Table 3 lists the performance comparison of the current main high-power IED driver control chips. When using high-power IED driver control chips, you can choose according to different application scenarios:

1) When higher power is required, you can choose a controller that does not integrate the power device in the chip, so that you can choose the power device separately according to the actual power demand;

2) When higher conversion efficiency is required, such as portable devices, you can choose a switch power supply type drive circuit;

3) When used in high-reliability equipment, you can choose a chip with comprehensive control functions such as temperature protection and fault alarm.

5 Conclusion

With the advancement of technology, the power of ultra-bright LEDs will be further improved and the cost will be reduced. High-efficiency and energy-saving ultra-bright LEDs will be widely used in the lighting field. Low-cost, high-reliability drive circuits are the key to ensuring that LEDs have lasting brightness.

Previous article:Research on the Water Cube LED Building Landscape Lighting Design

Next article:Technology that improves LCD TV LED backlight efficiency

Recommended ReadingLatest update time:2024-11-16 23:45

Analysis of three major problems of LED display

LED display screen

is a high-tech engineering product that integrates electronics, electricity,

computers

, communications, information, image processing,

optics

, materials, structures and other multidisciplinary technologies. The relevant engineering and technical problems in any of these disciplines w

[Power Management]

360-degree analysis of LED flip chip knowledge

What is LED flip chip? In recent years, flip chip technology has been emerging in the field of chips, especially in the high-power and outdoor lighting application market. However, due to its late development, many people do not know what LED flip chip is and what are the advantages of LED flip chip? Today, the ed

[Power Management]

Research status and progress of LED driver circuits for high-power backlight sources

1 Introduction

As the backlight source of LCD, LED has now shown a trend of replacing CCFL. Compared with traditional CCFL, LED backlight has the advantages of wide color gamut, good color reproduction, strong controllability, long life, and no mercury vapor and other harmful gases. LED backlight can also achie

[Power Management]

Power supply topology for LED lighting

This article provides an overview of LED characteristics and the trade-offs that occur when driving LEDs. It then provides a detailed discussion of the various switching power supply topologies that are suitable for driving and dimming LEDs, along with a detailed explanation of the relative benefits of these power s

[Power Management]

Involving Micro-LED mass transfer technology! Longli Technology obtained an invention patent certificate

Longli Technology recently issued an announcement stating that the company recently received an invention patent certificate issued by the State Intellectual Property Office. The patent is named "Method for preparing LED displays by hydrophilic and hydrophobic interface assembly" and the patent number is ZL20201072876

[Mobile phone portable]

Play with LED dot matrix 1: 16X64 single red dot matrix static display

//MCU: STC89C52

//Crystal: 22.1184M

//Display: HUB08 interface 16X64 single red dot matrix

//Display mode: static 16X16 Chinese characters

//Author: huqin

//QQ: 1766135164

//Website: http://www.51hei.com

//Time: 2013-05-13

#include

#include"zimo.h"

sbit SDAR1=P0^4; //Red data 1

sbit SDAR2=P3^3; //Red data 2

[Microcontroller]

Selection and Design of LED Drivers for Portable Applications

白光LED

广泛用于小型

液晶

显示

器(

LCD

)

面板

、键盘背光以及指示器应用。

高亮度LED

则用于手机和数位相机的闪光光源。这些应用需要最佳化的

驱动

器解决方案,能够延长电池使用时间、减小印制电路板(

PCB

)面积及高度。在这些应用领域,常见的

LED驱动

器方案涉及线性、

电感

型或电荷泵型不同拓扑结构,各有其特点。例如,电感型方案总效能最佳;电荷泵方案由于使用低高度陶瓷电容,佔用的电路板面积和高度极小;线性方案非常适合色彩指示器以及简单

[Power Management]

Two LED sorting methods based on chip and package

The human eye has a very high resolution for the color and

brightness

of light, and is particularly sensitive to differences and changes in color. The human eye has different sensitivities to light of different color wavelengths. For example, for light with a wavelength of 585nm, the human eye can sense when

[Power Management]

- Popular Resources

- Popular amplifiers

Recommended Content

Latest Power Management Articles

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

MoreSelected Circuit Diagrams

MorePopular Articles

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

MoreDaily News

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

Guess you like

- In the timer mode selection, 0: 32-bit free count 1: 16-bit reload count What is the difference between these two modes?

- Shanghai Semiconductor IC Company Epidemic Welfare Package PK, Too Lucky!

- Configuration Case Sharing--Modbus to Profinet Gateway Connecting ACS510 Inverter

- Modification of 4-20mA two-wire passive digital display meter Part 6 (general schematic diagram)

- Radio Frequency Learning Knowledge Consulting Network and Information Query Network (Collation)

- Pixel Pump, an open source vacuum pump using micropython

- Questions about PCF8583

- Answers to questions about programming the Lingdongwei MM32 MCU

- 16-bit MSP430G series microprocessor usage expansion

- [Reprint] STM32 drives VGA display to display IKS01A2 sensor data

Siemens PLC Project Tutorial

Siemens PLC Project Tutorial LED Cube Code

LED Cube Code ESP32-S3 source code

ESP32-S3 source code

京公网安备 11010802033920号

京公网安备 11010802033920号