1. Introduction

The current development trend of power management technology is that the huge market of Ethernet power supply technology is within reach. Power IC should have multiple functions. Power conversion IC integrates LDO and DC/DC converter, LED/LCD/OLED driver and other power semiconductor devices and power modules. However, this article only discusses the dimming control technology in LED/LCD/OLED driver. This is because LED has promoted the lighting revolution. LCD backlight is still the main LED application. Its LED has been used in various indoor and outdoor decorative lighting applications, and has begun to focus on general lighting applications such as flashlights, garden lights and street lights. These uses are opening up markets for LED lighting in the field of home and corporate lighting. The future of LED general lighting is the development of high-flux LEDs with a luminous efficiency of more than 100 lm/W, which enables LEDs to work with AC power without an inverter, thereby pushing LEDs closer to the mainstream general lighting market. Therefore, the brightness control of backlighting is an important technology in the LED lighting revolution, so there is an analysis and introduction of the new technical features and applications of LED lighting brightness control described below.

2. Topology of backlight brightness control

The topology of backlight brightness control is the dimming method, including dimming technologies such as pulse width modulation (PWM) using low-frequency and high-frequency signals, DC voltage control and resistor dimming. The following only introduces DC voltage control and PWM modulation technologies.

2.1 DC voltage dimming

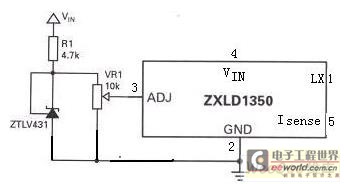

FIG1 is a typical DC voltage dimming schematic diagram using the ZETEX ZXLD1350 driver as an example.

The ZXLD1350 driver is a continuous inductive buck converter with built-in multi-switches and an output current of 350mA. The input voltage range is between 7V and 30V. Its feature is that the ZXLDl350 is equipped with a multi-function adjustment foot, which can adjust the brightness of the LED in a variety of ways by controlling the LED current.

Figure 1 Schematic diagram of DC voltage dimming

TLV431 is used as a shunt regulator to generate an external 1.25V voltage reference. This voltage reference is applied to the VRl potential to provide a dimming voltage of 0V-1.25V. Using an external regulator will affect the accuracy of the current setting. Using a 1% voltage reference makes the LED current more accurate compared to the internal voltage reference.

The adjustment pin can be overdriven by an external DC voltage (VADJ) to exceed the internal voltage reference and adjust the output current to exceed or below the rated value. The rated output current is:

Note that 100% brightness setting corresponds to VADJ = VREF. If VIN reaches its maximum value of 2.5V, RSENSE should be increased by a factor of 2. This will result in a small power reduction of 1% to 2%. The input impedance of the adjustment pin is 200kV + 20%. If the output impedance of the DC voltage is relatively high, this may have an effect.

2.2 Application of new dimming technology-PWM modulation technology

The wavelength of light emitted by an LED is closely related to the forward current driven into the device. To prevent color hue changes, the dimming method must be carefully selected. In the past, the most commonly used dimming method was to change the forward current or voltage on the device. Unfortunately, changes in current or voltage will change the wavelength of the light. This effect is proportional to the wavelength. Longer wavelengths experience the strongest change in color hue to current. In many applications, this result is unacceptable. If PWM modulation technology is used, the LED can be properly dimmed without causing wavelength changes. The on and off operation of the LED is achieved by changing the duty cycle. At this time, the forward current (1F) is a constant current.

2.2.1 Low-frequency and high-frequency dimming applications

⑴ Low frequency dimming. Since LEDs have a stable instantaneous drive current, they are suitable for low frequency dimming. The color temperature of the LED remains unchanged at all brightness levels. Another advantage of low frequency dimming is that the brightness can be reduced to 1%. Therefore, the dimming range is 100:1. The frequency is selected to avoid visible flicker. The PWM signal must be greater than 100Hz. If the selected frequency is too high, the built-in low-pass filter will start to merge the PWM signal and produce a nonlinear reaction. At the same time, the soft start function of the adjustment pin will cause a delay in the rise or fall of the PWM signal. This will make the LED current nonlinear, and the effect will be more significant when the frequency increases.

The common pulse width modulation diagram of low-frequency and high-frequency signals is shown in Figure 2. This figure is a pulse width modulation diagram taking the ZXLD1350 driver of ZETEX as an example.

Figure 2 Schematic diagram of pulse width modulation using the ZXLD1350 driver as an example

The upper limit of the low frequency is recommended to be 1kHz. The effect of possible audible noise from the inductor also needs to be considered. This may occur with some inductors with loose windings, and will be more noticeable at a PWM frequency of 1kHz than at 100Hz.

⑵High frequency dimming

If the system requires low radiation and input/output harmonics, high-frequency dimming is suitable. However, the dimming range will be reduced to 5:1. ZXLDl350 has a built-in low-pass filter that integrates high-frequency PWM signals and can perform DC dimming control. If the PWM frequency is higher than about 10kHz and the duty cycle is greater than the specified minimum value, the device will remain in operation and the output will remain unchanged.

⑶ Input buffer transistor

When PWM dimming is performed, the input bipolar transistor Q should use an open collector output (as shown in Figure 2). This ensures that the 200mV input shutdown threshold is reached. Direct PWM control can also be performed without a buffer transistor, but it must be done with extreme caution. This operation will overload the built-in 1.25V voltage reference. If 100% PWM (DC) uses a 2.5V input voltage, the output current into the LED will reach twice the normal current. And it may damage the ZXLDl350. Overdriving with a 5V logic signal will most likely damage the device when the rated voltage of the adjustment pin is exceeded.

⑷Soft start and decoupling capacitors

Any additional capacitor on the adjust pin will affect the PWM signal rise and fall. This needs to be taken into account as the rise time will increase by approximately 0.5ms/nF. Compare this to a 100Hz PWM, where the on time Ton at 50% duty cycle and the off time Toff are 5ms, and the on time Ton at 1% duty cycle is 0.1ms. A lnF on the adjust pin will result in a rise time of 0.5ms, which will cause errors and limitations when dimming at low duty cycles.

2.2.2 Accurately control brightness using linear and PWM input signals

This solution uses highly integrated technology. It is characterized by high efficiency and low power consumption, minimal external components, and accurate temperature/brightness control. The new LM3402/02HV switching regulator can meet the needs of this technology. Figure 3 shows the application diagram of the LM3402/02HV switching regulator.

The LM3402/02HV switching regulator in Figure 3 has a dedicated brightness control (DIM) pin that can accurately control brightness using linear and PWM input signals. Lighting systems that use LEDs to emit light generally use PWM dimming control to control light brightness, and this brightness control method has become a widely used standard in the industry. As long as the current of the forward LED is adjusted, the light output of the LED will increase or decrease in a linear manner, but most of the light bands will shift. Some applications do not have very strict requirements on color, so linear brightness control will still be used, but automotive lights such as brake lights, LCD backlights, and direct display RGB LEDs have extremely strict requirements on brightness and color, so these applications generally use PWM to control brightness.

Figure 3 Application diagram of LM3402/02HV switching regulator

The features of the LM3402/02HV switching regulator are as follows: input voltage range 6V ~ 75V, using the circuit layout of the buck regulator; can provide a constant drive current for the light-emitting diode, the feedback voltage is 200mV; when the RON pin is at a low potential, the shutdown current will be further reduced; accurate PWM brightness control; switching frequency up to 1MHz; with hysteresis function, and fixed conduction time. Therefore, the switching frequency (FSW) can be controlled within the entire input voltage range.

2.2.3 Application of a PWM controlled series switch

When the PWM frequency is above 100Hz, the human eye cannot perceive the individual pulses, but by integrating these pulses and interpreting them as brightness, the brightness can be changed linearly by linearly changing the duty cycle without any wavelength change. The most common method for adjusting the brightness of an LED is a PWM controlled series switch as shown in Figure 4. Because the forward operating current is relatively high, care must be taken when selecting the switch to ensure that the switch can handle the conduction losses.

Figure 4 Block diagram of PWM dimming technology using ST's new technology

To overcome this problem, this solution eliminates the series switch and also improves energy efficiency. Figure 4 shows the block diagram of the new dimming technology, which uses ST's new technology. This new technology exists in two control loops: a current loop and a voltage loop (shown in Figure 4). When maximum brightness is required, the current loop drives the LED with a stable forward current; during dimming operation, the current control loop will limit the maximum output current, while the voltage loop will maintain the output voltage below the sum of the threshold voltages of the LED array. When the LED is disconnected, the voltage loop will control the maximum output voltage. The block diagram of this new dimming technology can obtain a more cost-effective and efficient solution because the power switch is no longer used.

3. Add the application of intelligent brightness control technology

LED lighting applications can benefit from the intelligence of an MCU. An MCU can be used for a variety of tasks, including user interface, communication, battery status monitoring, and temperature measurement. Adding an MCU to a design does not mean adding complexity, space, or cost. Microchip offers the PIC10F series of MCUs, which come in a 6-pin SOT-23 package. The device also has an oscillator and reset circuit inside. Connecting power and ground gives you four I/0 pins that can be programmed to perform any desired task. The FPIC10F pins can be used as analog or digital pins. Two device variants in the FPIC10F family include an analog comparator module. Two FPIC10FP device variants include an 8-bit analog-to-digital converter (ADC). You only need to learn 33 assembly instructions to write code for the PICIOF.

One application of MCU in LED lighting is brightness control. Power LEDs can be dimmed by reducing the drive current. However, this is not the most efficient way to control the brightness of an LED. Power LEDs achieve their best efficiency at the highest rated drive current. Better efficiency can be achieved by using a low frequency PWM signal to switch the LED on and off. The PWM signal is connected to the enable input of the SMPS control IC. When turned on, the LED is always driven at the highest current.

The PIC10F206 device provides a user push button interface for the SMPS IC and generates PWM control signals. The PIC10F206 has an internal oscillator and reset circuit and does not require any external circuitry. In these applications, the PIC10F206 device can also be used for linear brightness control or monitoring battery status.

3.1 How to generate PWM control signal in the new solution

There are several ways to generate PWM control signals to control power supply circuits. Devices with a capture-compare-PWM(*) module can use the on-chip digital time base to generate PWM signals to control power supply circuits, as shown in Figure 5, which shows the output of a buck LED driver to Q1 using the PIC12HV615 comparator.

Figure 5 Buck LED driver using PIC12HV615 comparator

The signal pulse width is controlled by the MCU clock and duty cycle registers; the Enhanced* (E*) module enables one PWM signal to control 2 or 4 output pins for half-bridge or H-bridge control respectively; devices with comparators and E* modules can use the comparator signal to control the off time of the PWM signal; devices with comparators and PWM SR latches can use the comparator signal and/or clock pulses to switch the latch output; external PWM peripheral ICs can be used. This method is useful when multiple high-speed PWM channels are required, and the PWM signal can be generated using software and I/0 pins. This method is less expensive if the PWM frequency and duty cycle resolution requirements are not too high; PIC microcontrollers with on-chip comparators (such as PICl2F609) can be used to implement simple LED drivers. PICl2HV609 adds an internal regulator that can operate at a DC bus higher than 5V.

3.2 PWM control signal generation example - MCP1630 high-speed PWM controller

The MCP1630 provides another method for generating high-speed PWM signals for high-power LED drivers (see Figure 6).

Figure 6 High-power LED driver provided by MCPl630

The MCPl630 is an 8-pin device that contains the components required to generate an analog PWM control loop, including: an error amplifier, a comparator, and a high current output pin to drive a power transistor. The MCPl630 is designed to be used in conjunction with an MCU that provides a reference clock source. The PICHV615 MCU controls the PWM frequency and the maximum duty cycle. Depending on the application requirements, the switching frequency can be up to 1MHz. The MCU can also control the reference input of the error amplifier when dimming or soft-start functions are required. Multiple MCPl630 devices can be connected to one MCU to support multiple power supply channels.

The MCP1630 can be used to solve advanced power supply problems. When using multiple MCP1630 devices, a phase offset can be applied to each clock input to reduce bus current ripple. For applications that are sensitive to EMI, jitter can be applied to the clock signal to reduce the radiated energy of a given frequency.

4. Application of backlight brightness control technology

The brightness control of backlight LED can be achieved through PWM or constant current control. PWM brightness control requires a constant current driver to drive the LED, but the on/off time needs to be adjusted to achieve the desired brightness. Therefore, PWM is more complicated than direct constant current control. So a new solution is presented. To this end, RGB LED backlighting is used as an example to illustrate.

The pixels in an LCD display are divided into three primary color zones: red, green and blue. The color of a pixel is defined by the mixture of these three primary colors. With RGB backlighting, the driver must correct the brightness balance between the three primary colors red, green and blue to prevent white point shifts when the LED temperature changes. In addition, the driver must ensure that the correct intensity of light is maintained at any operating temperature. Compensation can be done in a closed loop or open loop. With closed loop compensation, a photosensitive sensor is used to measure the white point and its intensity. Conversely, with open loop compensation, the temperature is measured in advance and the brightness balance is adjusted using a predefined compensation curve. The LP5520 is an example of an RGB backlighting driver, which is an open loop compensated LED driver. Figure 7 shows the principle of open loop color compensation.

Figure 7 Principle of open-loop color compensation

The temperature compensation curves are measured using RGB LEDs in real applications, and these curves are programmed into the EEPROM memory inside the chip. The chip is integrated into an LCD display module, and the module manufacturer programs the compensation curves during production. In addition, the RGB LED backlight can also be used as an optimized color filter.

5. Conclusion

The above-mentioned efficient LED brightness control technology has several different topological methods, which can be summarized into two categories: one is to use an analog driver IC independently, or to use it with an MCU (to add intelligence); the other is to integrate the LED drive function into the MCU application. The choice of topology depends on the application, and the upcoming integrated multi-task mixed signal solution will inevitably bring new challenges to LED brightness control technology.

Previous article:Design of constant current drive power supply for high power LED lighting

Next article:Selection tips for high-power LED lamp beads and LED point light sources

Recommended ReadingLatest update time:2024-11-16 22:21

- Popular Resources

- Popular amplifiers

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- New real-time microcontroller system from Texas Instruments enables smarter processing in automotive and industrial applications

- 【CH579M-R1】+BH1750 light intensity detection

- Introduction to Several Common Laser Sensor Applications

- Both ends are TYPEC ports

- 5G Overview and Fundamentals

- TI's F28379D controlCARD for C2000 Real-Time Control Development Kit

- A Brief Analysis of Wireless Positioning Technology

- [TI recommended course] #C2837x Getting Started Guide#

- EEWORLD University Hall--One minute to understand: SRRC certification

- Unable to penetrate indoors? Wi-Fi encounters an awkward situation in urban configuration

- It turns out that she was the one who scolded Lei Jun for an hour as if he were a primary school student

Siemens PLC Project Tutorial

Siemens PLC Project Tutorial LED Cube Code

LED Cube Code ESP32-S3 source code

ESP32-S3 source code

京公网安备 11010802033920号

京公网安备 11010802033920号