A good horse deserves a good saddle - Gallium Future GaN and Nanochip micro-isolation drivers fly together to promote GaN advanced applications

The future is here, and the socio-economic value of gallium nitride is accelerating.

This article introduces the technical cooperation plan between GaN and Nanochip in GaN. The compact cascade GaN devices provided by GaN cooperate with Nanochip's isolation drivers . The isolation drivers ensure effective protection of GaN devices under abnormal working conditions, perfectly demonstrating the core value of GaN in advanced applications with high efficiency and low loss, allowing engineers to use GaN with confidence.

Ordinary consumers began to understand and accept GaN starting with GaN PD fast charging in 2018. With GaN's excellent switching characteristics, it can work at high frequencies and achieve high conversion efficiency. GaN PD fast charging has successfully achieved miniaturization and lightweight, making it easy for consumers to carry and greatly improving user experience. In the past few years, the penetration rate of GaN in PD fast charging has gradually increased, and consumers' perception of GaN is "GaN = black technology". PD fast charging using GaN can be sold for a few hundred yuan, while ordinary PD fast charging using silicon devices is often priced at less than one hundred yuan. The application of GaN soon expanded from PD fast charging to other consumer products, and the output power gradually increased from 30W and 65W to 120W or even higher power.

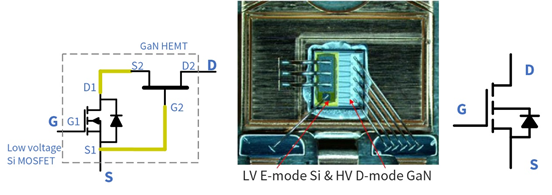

Ordinary consumers, and even engineers who don't know much about GaN, generally believe that GaN can only achieve an output power of tens of watts to more than a hundred watts. This is basically true, because enhanced GaN currently only has SMD packaging forms such as QFN/DFN and TOLL, and it is difficult to solve the heat dissipation problem in medium and high power application scenarios. However, GaN uses a unique compact cascade technology, and the packaging forms include QFN/DFN, TOLL, TO-220 and TO-247, etc., to meet a variety of application scenarios such as low power (30W~300W), medium power (300W~1kW) and high power (1kW~6kW).

At the beginning of its establishment, Gallium Future focused on the application and market expansion of small and medium power. However, starting from 2022, the company has focused on the medium and large power application market and made many breakthroughs in the application fields of portable energy storage bidirectional inverters, server power supplies, computing power supplies and plant lighting power supplies. The steady increase in the market's acceptance of gallium nitride is mainly due to the general consensus of society on energy conservation, emission reduction and high-efficiency power conversion.

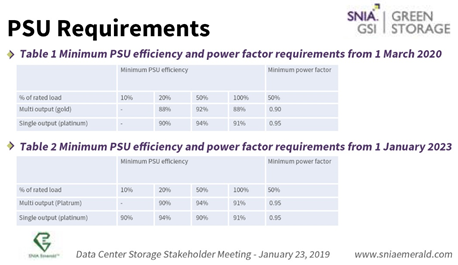

80+ energy efficiency standards

Technical Specifications for Energy Efficiency Grading Certification of Embedded Power Supplies

EU lot9 storage power efficiency requirements

To achieve 80+ 96% titanium efficiency, or CQC embedded power supply output within 40V energy efficiency level VI 96% peak efficiency and level VII 97% peak efficiency, the most cost-effective solution is the GaN totem pole bridgeless PFC topology plus resonant soft switching LLC topology.

Part 1: GaN achieves high conversion efficiency and enables energy conservation and emission reduction

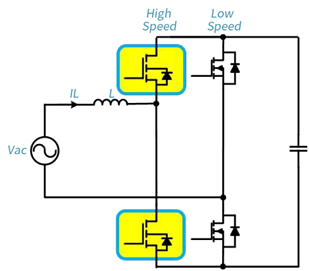

With its excellent switching characteristics and “zero” reverse recovery charge Qrr, GaN is particularly suitable for CCM BTP PFC (Continuous Current Mode Bridgeless Totem-Pole Power Factor Correction) topology. Compared with other commonly used traditional topologies, its main advantages include:

Fewest components, lowest cost, and highest cost performance

Highest efficiency, greatly reduced losses, simple thermal management, and natural heat dissipation

High power per unit, high power density and light weight

Simple control, energy can flow in both directions, rectifier and inverter are used in one machine

GaN-based CCM BTP PFC topology

Part II: Challenges and countermeasures of GaN in medium and high power applications

As a leading domestic supplier of compact cascaded GaN devices, GaN Future has a GaN wafer yield of over 95%. Combined with the advantages of localized supply chain and resource integration, it has outstanding cost performance. Compared with enhanced GaN, the main advantages of GaN Future's compact cascaded GaN include:

Vgs threshold voltage lower limit up to 3.5V, strong anti-interference performance, especially suitable for high frequency, hard switching and high power applications

Vgs threshold voltage upper limit up to 20V (static), 30V (dynamic), drive compatible with Si MOSFET driver

No need for negative pressure shutdown, simple peripheral circuit

Half -individual diode, no need for anti-parallel SBD to reduce freewheeling loss and improve efficiency

Full range of packages, including SMD QFN/DFN/TOLL and plug-in TO-220/TO-247, covering the full power range of application scenarios

Direct alternative materials are available, and continuous large-scale supply is worry-free

However, there are some limitations in general for GaN, including weak avalanche capability, and the drain-source needs to improve overvoltage capability; the current impact resistance needs to be improved, and the upper and lower tubes need to be prevented from being directly connected in the half-bridge circuit. For the former, the future GaN overvoltage capability is outstanding. For example, for a device with a rated withstand voltage of 650V, its Vds has a non-repeatable peak voltage duration of up to 30us at 800V and a repeatable peak voltage duration of up to 750V. For the latter, the driver needs to have an interlock function, that is, when the upper and lower tube drive voltages given by the DSP digital controller or analog controller are both high, the driver locks the upper and lower tube drive voltages to low through its own logic control to ensure that the GaN device will not be directly connected and work safely. In the case of AC input dynamics, DC output dynamics, lightning surges, etc., the DSP digital controller or analog controller may output a false action signal due to external interference. The driver with the interlock function can effectively protect the GaN device.

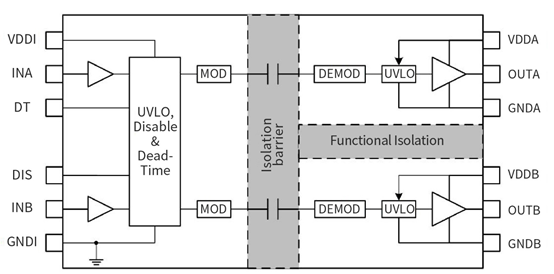

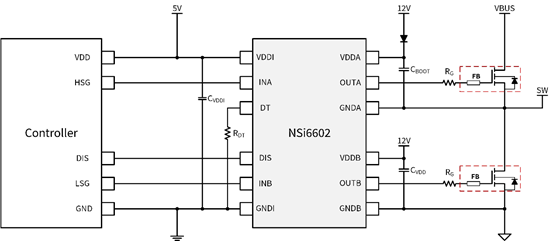

The Gallium Future application development team has rich experience in digital control and analog control, and has standardized the half-bridge GaN drive circuit, that is, uniformly adopting the Nanochip NSi6602 isolated driver.

NSi6602 Isolation Driver System Block Diagram

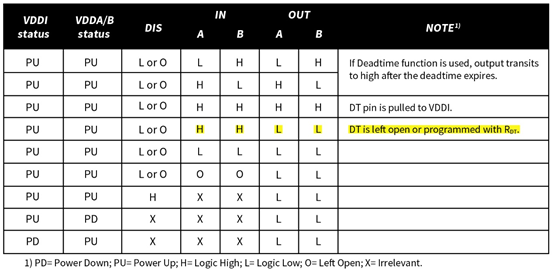

According to the logic table of NSi6602, the DT pin realizes the output interlock function or the dead zone adjustment function. At the same time, the input signal and output signal of NSi6602 are isolated, which is convenient for PCB board wiring and further improves the anti-interference performance. The common mode interference resistance CMTI of NSi6602 is as high as 150V/ns, which is very important in high-power short circuit and overcurrent protection. In addition, the differential mode voltage of its upper and lower drives can reach 1500V, which is also suitable for 900V GaN devices and three-phase system applications.

NSi6602 Logic Table

A good horse deserves a good saddle. In the future, GaN and Nanochip's micro-isolation drivers will fly together in pairs. The isolation drivers ensure the effective protection of GaN devices under abnormal working conditions, perfectly demonstrating the core value of GaN's high efficiency and low loss in advanced applications, allowing engineers to adopt GaN with confidence.

In actual applications, BTP PFC uses two NSi6602s to drive two GaN fast transistors and two Si MOSFET slow transistors respectively. In the LLC part, if it is a half-bridge LLC, one NSi6602 is used, and if it is a full-bridge LLC, two NSi6602s are used.

NSi6602 Typical Application Diagram

In response to different application requirements, NSi6602 provides a series of products with different isolation voltage levels and package types. Please refer to the table below for details.

NSi6602 Isolation Driver Product Selection Table

Part 3: Rich Application Cases

GaN bidirectional inverter for portable energy storage:

The AC side supports global voltage range, including Central European and American and Japanese standards

Typical voltage on DC side is 48V, customizable

Power is 2kW, supports various overload operations

BTP PFC uses two G1N65R035TB-N (35mΩ/650V, TO-247-3L) GaN and two NSi6602B-PSDNR, operating at 65kHz

The full-bridge LLC uses four G1N65R070TA-H (70mΩ/650V, TO-220) GaN and two NSi6602B-PSDNR, with a resonant frequency of 120kHz

Support multiple machines in parallel to increase output power

Peak efficiency 96% @ 220Vac

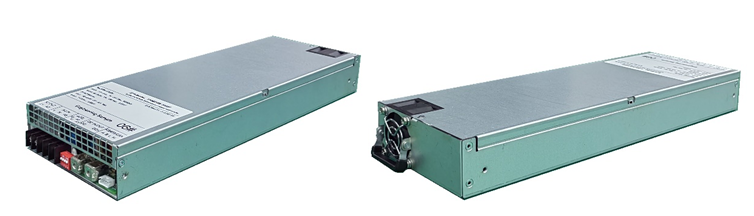

2.5kW high efficiency, high power density, fully digital controlled, conduction-cooled server power supply

AC input voltage: 90Vac~264Vac, low voltage derating

DC output: 12.2V/205A, Vsb/2.5A

Output power is 2.5kW, supporting multiple machines in parallel

BTP PFC uses two G1N65R035TB-N (35mΩ/650V, TO-247-3L) GaN and two NSi6602B-PSDNR, operating at 65kHz

The half-bridge LLC uses a NSi6602B-PSDNR with a resonant frequency of 125kHz

Peak efficiency 96.2%, meeting 80+ Titanium efficiency certification

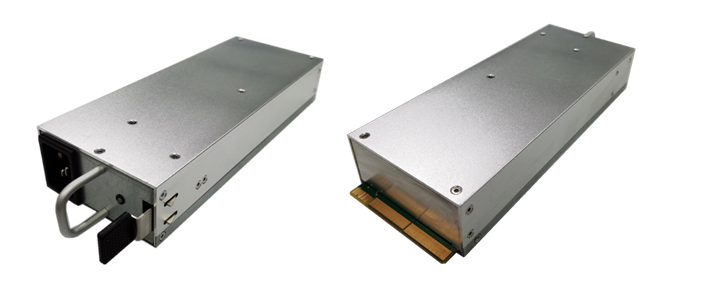

3.6kW high-efficiency computing power supply

AC input voltage: 180Vac~300Vac

DC output voltage: 11.5V-15.5V/240A, 3.6kW

BTP PFC uses two G1N65R035TB-N (35mΩ/650V, TO-247-3L) GaN and two NSi6602B-PSDNR, operating at 65kHz

LLC uses two NSi6602B-PSDNRs with a resonant frequency of 100kHz

Previous article:ROHM signs joint development agreement with Mazda and Imasen Electric for e-Axle inverter using silicon carbide power modules

Next article:ROHM develops MOSFET with insulating structure, small size and ultra-low power consumption

Recommended ReadingLatest update time:2024-11-17 01:48

- Popular Resources

- Popular amplifiers

-

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun)

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun) -

Modern Product Design Guide

Modern Product Design Guide -

Modern arc welding power supply and its control

Modern arc welding power supply and its control -

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun)

Small AC Servo Motor Control Circuit Design (by Masaru Ishijima; translated by Xue Liang and Zhu Jianjun, by Masaru Ishijima, Xue Liang, and Zhu Jianjun)

- MathWorks and NXP Collaborate to Launch Model-Based Design Toolbox for Battery Management Systems

- STMicroelectronics' advanced galvanically isolated gate driver STGAP3S provides flexible protection for IGBTs and SiC MOSFETs

- New diaphragm-free solid-state lithium battery technology is launched: the distance between the positive and negative electrodes is less than 0.000001 meters

- [“Source” Observe the Autumn Series] Application and testing of the next generation of semiconductor gallium oxide device photodetectors

- 采用自主设计封装,绝缘电阻显著提高!ROHM开发出更高电压xEV系统的SiC肖特基势垒二极管

- Will GaN replace SiC? PI's disruptive 1700V InnoMux2 is here to demonstrate

- From Isolation to the Third and a Half Generation: Understanding Naxinwei's Gate Driver IC in One Article

- The appeal of 48 V technology: importance, benefits and key factors in system-level applications

- Important breakthrough in recycling of used lithium-ion batteries

- Innolux's intelligent steer-by-wire solution makes cars smarter and safer

- 8051 MCU - Parity Check

- How to efficiently balance the sensitivity of tactile sensing interfaces

- What should I do if the servo motor shakes? What causes the servo motor to shake quickly?

- 【Brushless Motor】Analysis of three-phase BLDC motor and sharing of two popular development boards

- Midea Industrial Technology's subsidiaries Clou Electronics and Hekang New Energy jointly appeared at the Munich Battery Energy Storage Exhibition and Solar Energy Exhibition

- Guoxin Sichen | Application of ferroelectric memory PB85RS2MC in power battery management, with a capacity of 2M

- Analysis of common faults of frequency converter

- In a head-on competition with Qualcomm, what kind of cockpit products has Intel come up with?

- Dalian Rongke's all-vanadium liquid flow battery energy storage equipment industrialization project has entered the sprint stage before production

- Allegro MicroSystems Introduces Advanced Magnetic and Inductive Position Sensing Solutions at Electronica 2024

- Car key in the left hand, liveness detection radar in the right hand, UWB is imperative for cars!

- After a decade of rapid development, domestic CIS has entered the market

- Aegis Dagger Battery + Thor EM-i Super Hybrid, Geely New Energy has thrown out two "king bombs"

- A brief discussion on functional safety - fault, error, and failure

- In the smart car 2.0 cycle, these core industry chains are facing major opportunities!

- Rambus Launches Industry's First HBM 4 Controller IP: What Are the Technical Details Behind It?

- The United States and Japan are developing new batteries. CATL faces challenges? How should China's new energy battery industry respond?

- Murata launches high-precision 6-axis inertial sensor for automobiles

- Ford patents pre-charge alarm to help save costs and respond to emergencies

- Crowdfunding 3,000 yuan to buy batteries for needle penetration tests, BYD VS CATL technology game

- [Evaluation of EC-01F-Kit, the NB-IoT development board of Anxinke] + Alibaba Cloud connection to upload light illumination data

- Operate the lmx2582 registers through stm32, the project file is in the attachment

- 【ESP32-S2-Kaluga-1 Review】2. Update the firmware

- Speed sensor

- How to use Labview to perform secondary development on Ginkgo 2

- What is iPhone USB PD fast charging?

- 5. [Learning LPC1768 library functions] 485 experiments

- HC8819 data, the step-down chip found when disassembling the car charger

- W806-KIT Complete Information Package

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun)

Siemens Motion Control Technology and Engineering Applications (Tongxue, edited by Wu Xiaojun)

京公网安备 11010802033920号

京公网安备 11010802033920号